Let Every Smile Light Up Your Trust

Xielifeng Are Your Machining Experts!

IOS 9001

IOS 14001

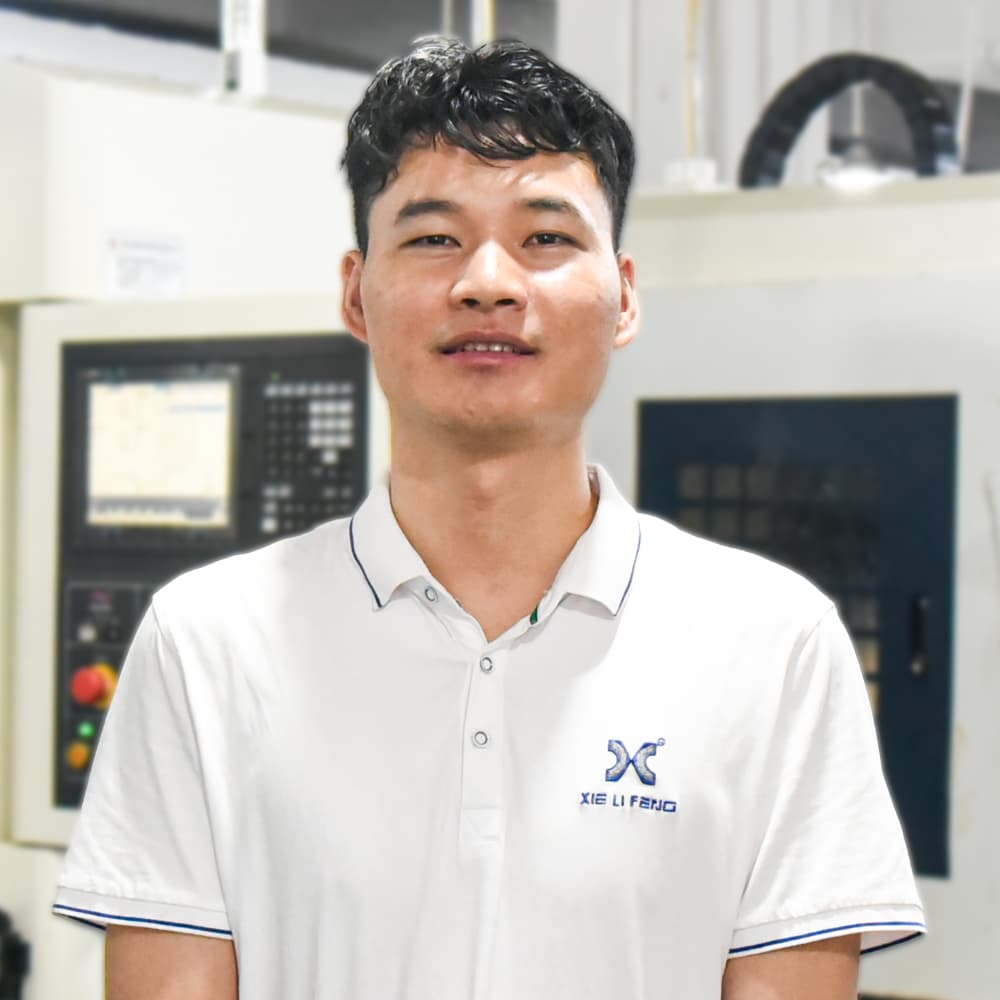

Mr. Zhang

Founded Xielifeng CNC machining parts factory in 1999. With a background in mechanical engineering and years of manufacturing experience, he grew the factory from a small workshop to an industry leader. Focused on innovation and quality control, he developed techniques that improved efficiency and product quality. He has received several industry awards and shared his insights at various forums.

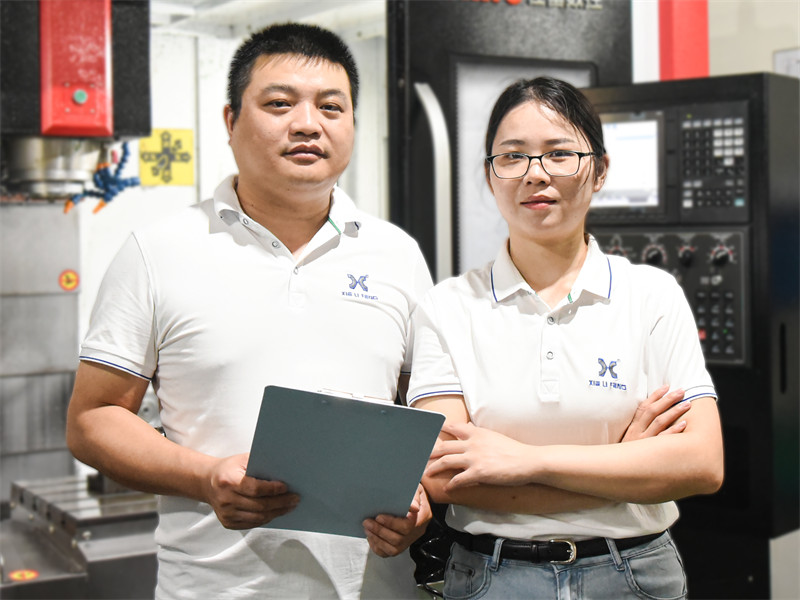

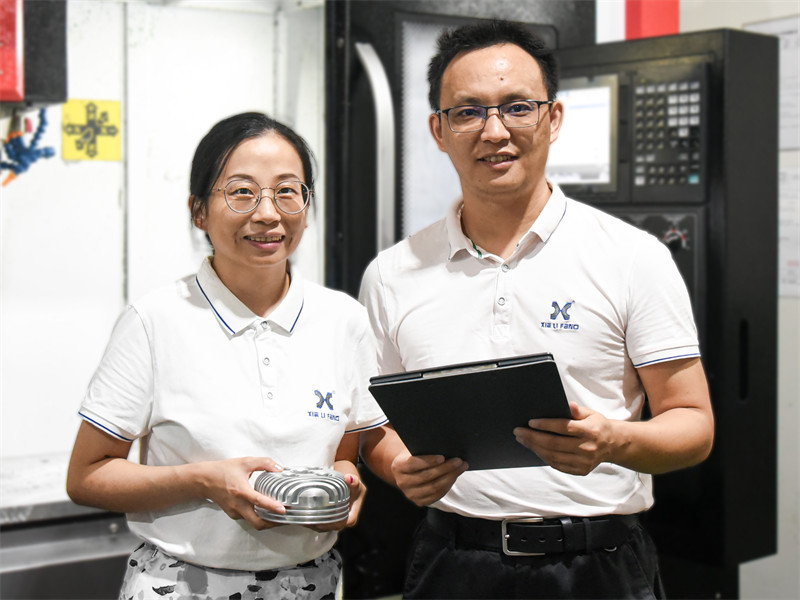

Xielifeng Gold Service Team

When you inquire with Xielifeng, a team of at least two experts will assist you. Our experienced and skilled team offers flexible, efficient solutions to ensure high-quality, customized machining.

If you have preferred experts, let us know!

Rapid Prototyping Expert Team

Business Manager: Stefen

With 8 years of experience, specializes in rapid response and flexible order management, ensuring timely fulfillment of customer needs.

Engineer: Henry

Specializing in rapid prototyping, proficient in various techniques, and capable of delivering high-quality prototypes in a short time.

Mass Customization Expert Team

Business Manager: Peter

With over 10 years of expertise in managing high-volume orders, ensures efficient production and on-time delivery.

Engineer: Emily

Skilled in mass production processes and automation line design, guaranteeing efficient and high-quality output.

5-Axis Machining Expert Team

Business Manager: Crystal

Strong process knowledge and communication skills ensure smooth execution, timely delivery, and cost optimization for clients.

Engineer: James

Skilled in handling complex shapes with precision, committed to delivering top quality in every project, regardless of complexity.

Multi-Industry Expert Team

Business Manager: Jenny

With a decade of multi-industry sales experience, excels at delivering tailored solutions supported by deep industry expertise.

Engineer: Daniel

With 15 years of machining experience and extensive material knowledge, capable of handling complex parts and diverse materials.

Surface Finishing Expert Team

Business Manager: David

With 7 years of experience in surface treatment, skilled in various processes to deliver optimal solutions for clients.

Engineer: Benjamin

Proficient in anodizing, plating, and coating techniques, ensuring excellent product appearance and performance.

Multi-Industry Expert Team

Business Manager: Harry

Skilled in integrating diverse manufacturing processes to deliver comprehensive solutions for clients.

Engineer: Sophia

Specialized in sheet metal, die casting, and plastic injection, providing smooth integration with machining for optimized solutions.

Professional Engineer Team

Xielifeng takes pride in our team of highly experienced professional engineers who excel in their respective fields and have exceptional skills and extensive practical experience. Whether you need automotive parts, high-precision aerospace components, new energy parts, industrial equipment parts, consumer electronics components, or specialized parts for other industries, our engineers can provide you with high-quality and reliable solutions.

Automotive Sector

Henry

10 years of experience

Familiar with automotive industry standards.

Ensures products meet strict requirements.

Aerospace Sector

James

12 years of experience

Focuses on high-precision and high-demand parts processing.

Ensures products meet aerospace standards.

New Energy Sector

Julia

9 years of experience

Proficient in new energy material processing technology.

Provides efficient and sustainable solutions.

Industrial Sector

Bella

10 years of experience

Specializes in high-strength and durable parts processing.

Ensures product reliability in harsh environments.

3C Electronics Sector

Grace

6 years of experience

Expert in precision consumer electronics parts processing.

Ensures high performance and reliability of products.

3C Electronics Sector

Lucy

8 years of experience

High-frequency communication equipment parts processing.

Ensures high precision and stability of products.

Medical Sector

Daniel

7 years of experience

Proficient in precision processing of medical equipment parts

Skilled in medical parts machining, ensuring precision.

Appliance Sector

Andrew

9 years of experience

Efficient and durable machining of household appliance parts.

Ensuring long-lasting reliability and performance.

Lighting Sector

Nora

7 years of experience

Focuses on energy-efficient and high-performance lighting parts.

Provides high-quality and long-lasting products.

Firefighting Sector

Benjamin

10 years of experience

Proficient in durable processing of firefighting equipment parts.

Ensures product reliability and safety in extreme environments.

Team Culture

Customer First, Quality First

The Xielifeng team prioritizes customer satisfaction, offering tailored solutions and maintaining close communication. We ensure high quality through strict control from material selection to final testing

Innovation & Learning

The Xielifeng team focuses on innovation, adopting the latest technologies and equipment while encouraging employee creativity. We enhance skills through training to stay competitive in a changing market.

Teamwork and Diversity

We know teamwork is crucial to success. Engineers and business managers work together to meet customer needs. We welcome diverse backgrounds, promote inclusivity, and foster a supportive environment for innovation and growth.

Environmental & Safety

We prioritize sustainability with eco-friendly materials and energy-efficient equipment, reducing waste and emissions. Employee safety is key, with strict adherence to safety standards and protective equipment.

Team Honors and Activities

Internal Seminars: Employees showcase innovations and learn together.

Visiting and Learning: Learn the latest technologies and equipment.

External Competitions: Participate in skill competitions to improve technical expertise.

Regular Maintenance: Regular training to maintain optimal equipment condition.

Standards: Train to follow ISO 9001 and other international standards, ensuring global quality.

Technical Exchanges: Share technology, understand needs and customize solutions.

Green Practices: Implement eco-friendly measures and engage in community activities.