The composition and function of CNC system

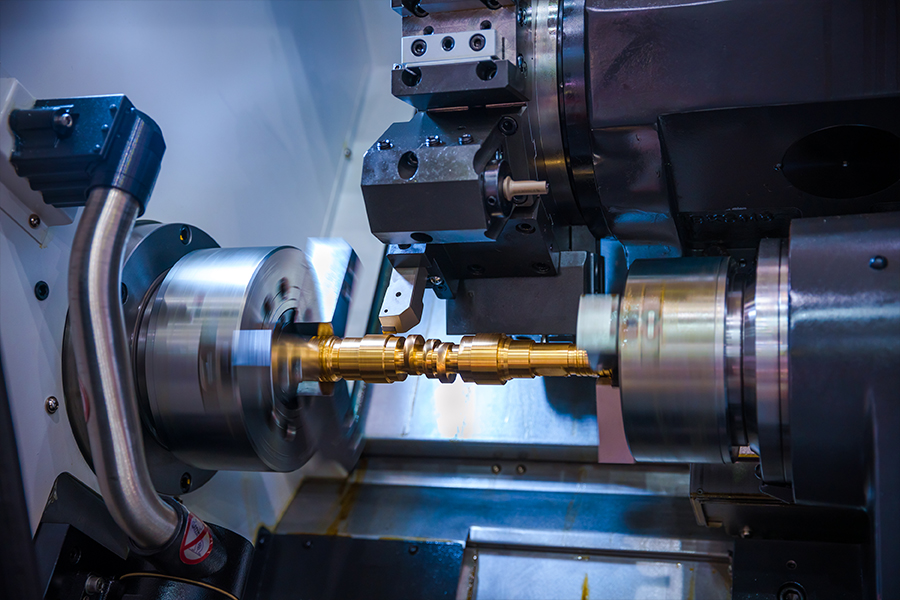

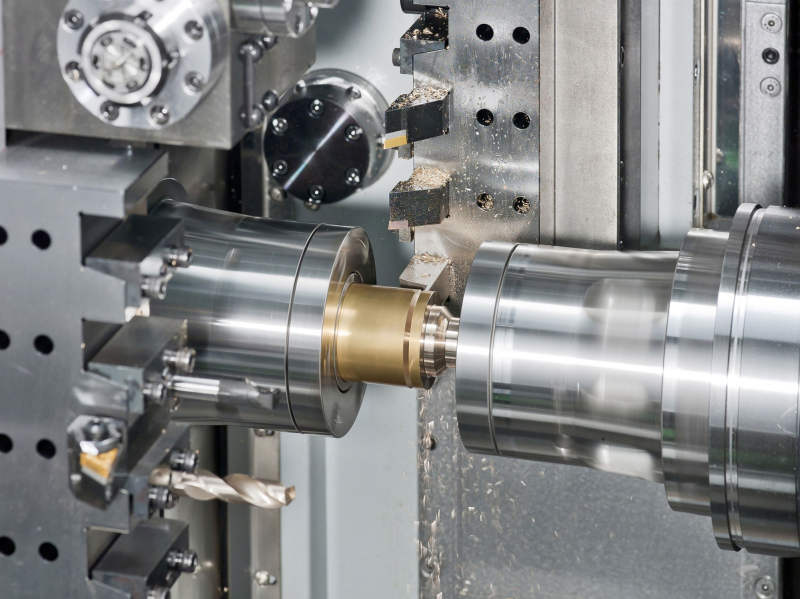

In mechanical manufacturing technology, the geometry of the parts to be processed is ever-changing, but in general, they are rotary parts and non-rotary parts. The rotary part machining mainly includes holes, shafts, tapered surfaces, curved surfaces and threads machining, etc., and the non-revolving parts mainly include the processing of holes, plane contours, three-dimensional contours, and […]

The composition and function of CNC system Read More »