Stamping is the process of placing flat sheet metal in either blank or coil form into a stamping press where a tool and mold surface forms the metal into a net shape. Stamping includes a variety of sheet-metal forming manufacturing processes, such as punching using a machine press or stamping press, blanking, embossing, bending, flanging, and coining. This could be a single stage operation where every stroke of the press produces the desired form on the sheet metal part or could occur through a series of stages. The process is usually carried out on sheet metal, but can also be used on other materials, such as polystyrene. Progressive dies are commonly fed from a coil of steel, coil reel for the unwinding of the coil to a straightener to level the coil and then into a feeder which advances the material into the press and die at a predetermined feed length. Depending on part complexity, the number of stations in the die can be determined. Stamping is usually done on the cold metal sheet.

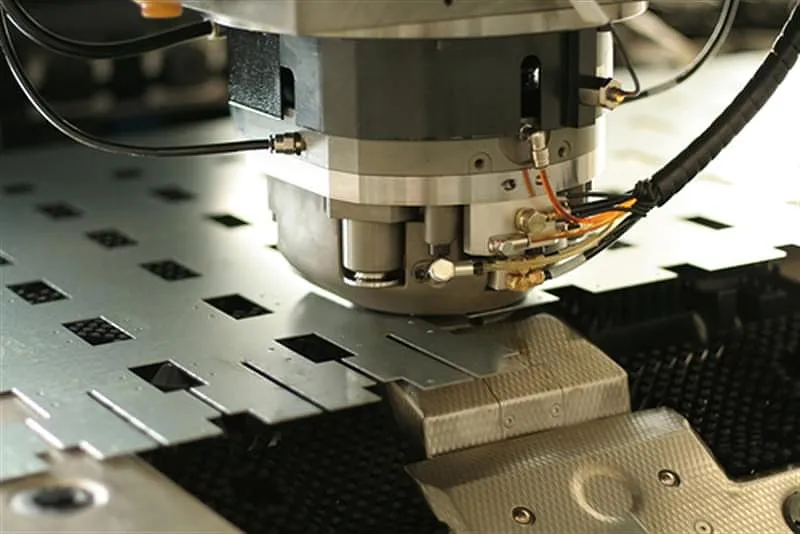

CNC punching is a sheet metal manufacturing process that is carried out by CNC punch presses. These machines can be either a single head and tool rail design or multi-tool turret design. The CNC punching machine is basically programmed to move a sheet of metal in an x and y direction so as to accurately position the sheet under the machine’s punching ram ready to punch a hole or form. The processing range for most CNC punch presses is 0.5mm to 6.0mm thick in a range of materials including steel, SGCC, stainless steel and aluminum etc. The choice of hole-punched can be as simple as a circle or rectangle right through to special shapes to suit a specific cut out design. By using a combination of single hits and overlapping geometries, complex sheet metal component shapes can be produced. The machine may also punch 3D forms such as dimples, thread plunges and electrical knockouts etc. on either side of the sheet, which is often employed in sheet metal enclosure design. Some modern machines may have the ability to tap threads, fold small tabs, punch sheared edges without any tool witness marks making the machine very productive within the component cycle time. The instruction to drive the machine to create the desired component geometry is known as the CNC program.

Get An Instant Online Quote Now

For your convenience’s sake, please directly forward your RFQ to our support email [email protected], we will give you the quote with 24 hours. It will be better if you send us both 2D and 3D drawings.

FAQs:

3-5 days.10-15 days for bulk orders.Depends on your specific items,We can expedite for you.

First full size inspection—Mass production—Check process (3 hours sampling)—100% Shipping random checks. We have professional QC team, control the quility during the mass production and inspect the completely goods before shipping.

Kindly please provide the product drawing in PDF, and will be better you can provde in DWG or STEP.

YES,OEM/ODM,customer’s logo is welcomed.

Regularly doing 30%-50% deposit and 50%-70% balance by T/T, Western Union,Paypal,other payment terms also can be discussed based on our cooperation.