Cutting speed and feed rate of CNC machining center

1: Spindle speed=1000Vc/πD

2: The maximum cutting speed (Vc) of general tools: 50 m/min for high-speed steel; 150 m/min for superhard tools; 250 m/min for coated tools; 1000 m/min for ceramic and diamond tools 3 Brinell hardness for processing alloy steel When =275-325, high-speed steel tool Vc=18m/min; carbide tool Vc=70m/min (cutting amount=3mm; feed rate f=0.3mm/r)

There are two calculation methods for the spindle speed. The following examples are given: Spindle speed: one is G97 S1000, which means that the spindle rotates 1000 revolutions per minute, which is commonly referred to as constant speed. The other is that G96 S80 is constant surface speed, which is the spindle speed determined by the workpiece surface.

There are also two feed rates. G94 F100 means that the tool travel distance in one minute is 100 mm. The other is G95 F0.1, which means that the tool feed size is 0.1 mm for each revolution of the spindle. Tool selection and cutting amount determination in NC machining

The selection of the tool and the determination of the cutting amount are important contents in the CNC machining process, which not only affect the machining efficiency of the CNC machine tool, but also directly affect the machining quality. The development of CAD/CAM technology makes it possible to directly use CAD design data in CNC machining, especially the connection between the microcomputer and the CNC machine tool, so that the entire process of design, process planning and programming can be completed on the computer, and generally no output is required. Specialized craft files.

Now, many CAD/CAM software packages provide automatic programming functions. These software generally prompt the related issues of process planning in the programming interface, such as tool selection, machining path planning, cutting amount setting, etc. The programmer only needs to set the relevant issues. parameters, the NC program can be automatically generated and transmitted to the CNC machine tool to complete the processing. Therefore, the tool selection and cutting amount determination in CNC machining are completed in the state of human-computer interaction, which is in sharp contrast with ordinary machine tool processing. At the same time, programmers must master the basic principles of tool selection and cutting amount determination. Fully consider the characteristics of CNC machining when programming. In this paper, the problems of tool selection and cutting amount determination that must be faced in NC programming are discussed, some principles and suggestions are given, and the problems that should be paid attention to are discussed.

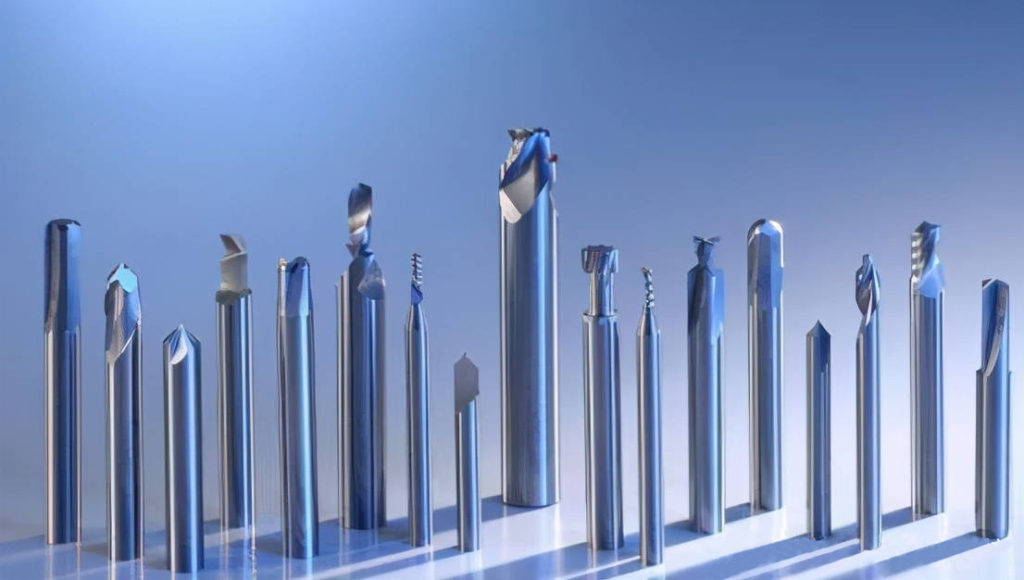

Selections of CNC Machining Tools

The tool selection is carried out under the man-machine interaction state of NC programming. The tool and tool holder should be correctly selected according to the processing capacity of the machine tool, the performance of the workpiece material, the processing procedure, the cutting amount and other related factors. The general principle of tool selection is: easy installation and adjustment, good rigidity, high durability and precision. On the premise of meeting the processing requirements, try to choose a shorter tool holder to improve the rigidity of tool processing.

When selecting a tool, the size of the tool should be adapted to the surface size of the workpiece to be machined. In production, end mills are often used to process the peripheral contours of plane parts; when milling planes, carbide insert milling cutters should be selected; when machining bosses and grooves, high-speed steel end mills should be selected; machining blank surfaces or rough machining When drilling holes, corn milling cutters with carbide inserts can be selected; for the processing of some three-dimensional profiles and variable bevel contours, ball end milling cutters, annular milling cutters, conical milling cutters and disc milling cutters are often used.

When machining free-form surfaces, since the cutting speed of the end of the ball nose tool is zero, in order to ensure the machining accuracy, the cutting line spacing is generally very dense, so the ball nose is often used for the finishing of the surface. The flat-end tool is superior to the ball-end tool in terms of surface processing quality and cutting efficiency. Therefore, as long as the premise of ensuring that it does not cut, whether it is roughing or finishing of the curved surface, the flat-end tool should be preferred. In addition, the durability and accuracy of the tool have a great relationship with the price of the tool. It must be noted that in most cases, although the choice of a good tool increases the tool cost, the resulting improvement in processing quality and processing efficiency , the entire processing cost can be greatly reduced.

On the machining center, various tools are installed on the tool magazine, and the tool selection and tool change can be performed at any time according to the program regulations. Therefore, a standard tool holder must be used, so that the standard tools for drilling, boring, expanding, milling and other processes can be quickly and accurately installed on the machine tool spindle or tool magazine. Programmers should understand the structure size, adjustment method and adjustment range of the tool holder used on the machine tool, so as to determine the radial and axial dimensions of the tool during programming. At present, the machining centers in my country use the TSG tool system, and the tool shank has two types: straight shank (three specifications) and taper shank (four specifications), including a total of 16 kinds of tool shanks for different purposes.

In economical CNC machining, since the sharpening, measurement and replacement of tools are mostly performed manually, it takes a long time to assist. Therefore, the arrangement order of the tools must be reasonably arranged. Generally, the following principles should be followed: minimize the number of tools; after a tool is clamped, all processing parts that it can perform should be completed; the rough and finishing tools should be used separately, even if they are tools of the same size; first milling and then drilling ; Perform surface finishing first, and then perform two-dimensional contour finishing; when possible, the automatic tool change function of the CNC machine tool should be used as much as possible to improve production efficiency, etc.

Related searches: cnc machining aluminum. stainless steel, brass parts, brass turning parts