Xielifeng,

the Plastic Materials Expert,

Meeting All Your Machining Needs.

All uploads are secure and confidential. Learn more.

ISO 9001

ISO 14001

Plastic Material Selection

| Material Name | Performances | Industry | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| ABS | Good overall properties, high impact strength | Consumer electronics, Automotive | ||||||||

| PEI Amber | High mechanical strength, high temperature resistance | Aerospace, Electronics | ||||||||

| HDPE | Good chemical resistance, abrasion resistance | Food processing, Chemical | ||||||||

| PE | Strong chemical resistance, easy to process | Packaging, Agriculture | ||||||||

| PP | Lightweight, good chemical resistance | Automotive, Packaging | ||||||||

| PBT | High mechanical strength, heat resistance | Electronics, Automotive | ||||||||

| PPS | Very high chemical stability, heat resistance | Chemical, Electronics | ||||||||

| PC | High impact strength, transparency | Safety, Medical | ||||||||

| PA6G | High strength, abrasion resistant | Machinery, Automotive | ||||||||

| Nylon MoS2 | Self-lubricating, high abrasion resistance | Industrial machinery | ||||||||

| PTFE | Extremely low friction coefficient, very high chemical resistance | Chemical, Aerospace | ||||||||

| PVDF | Strong chemical resistance, abrasion resistant | Chemical, Construction | ||||||||

| PCTFE | Excellent chemical stability, low gas permeability | Aerospace, Medical | ||||||||

| PVC Grey | Good chemical resistance, high rigidity | Construction, Industrial | ||||||||

| UHMW Black | Extremely high abrasion resistance, high impact strength | Food processing, Packaging | ||||||||

| PEEK | High-performance plastic, excellent temperature and chemical resistance | Aerospace, Medical | ||||||||

| PETP | Good mechanical and electrical properties | Electronics, Machinery | ||||||||

| POM | High rigidity, excellent wear resistance and dimensional stability | Machinery, Automotive | ||||||||

| G10 | Excellent electrical insulation, moisture resistant | Electronics | ||||||||

| White Nylon | High strength, wear-resistant, good chemical resistance | Automotive, Electronics | ||||||||

| Food Grade PET | Non-toxic, transparent, good chemical resistance | Food processing | ||||||||

| Green PP Rod | Strong chemical resistance, impact resistant | Chemical, Medical | ||||||||

| Carbon Fiber Plate | High strength, lightweight, corrosion-resistant | Aerospace, Sports | ||||||||

| Transparent Acrylic | High transparency, easy to process, impact resistant | Advertising, Construction | ||||||||

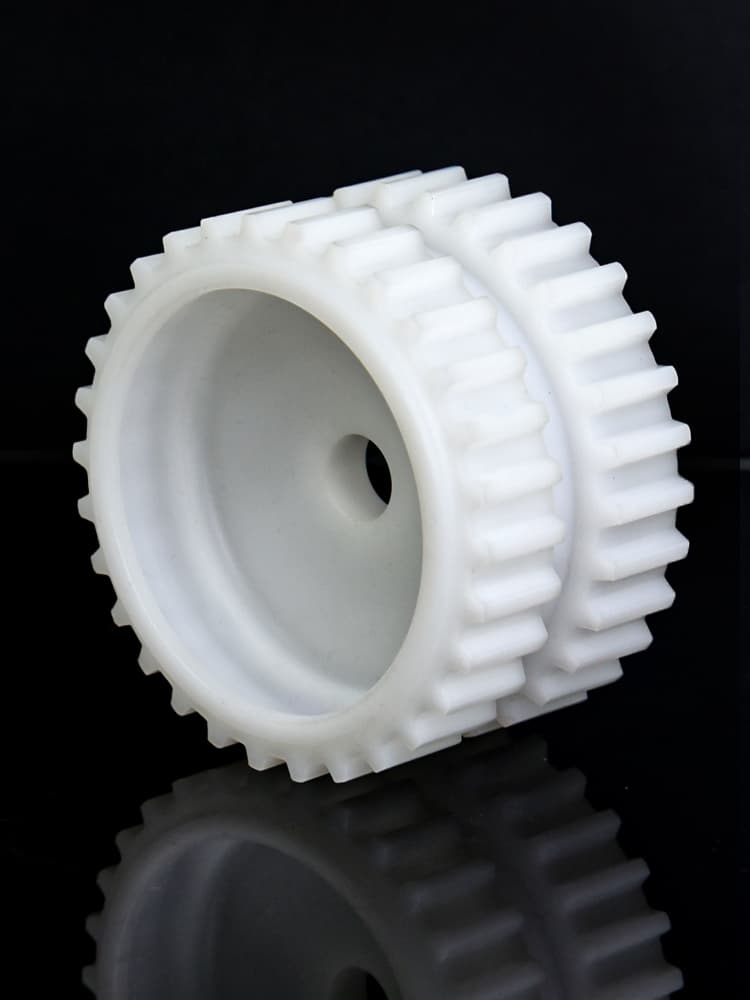

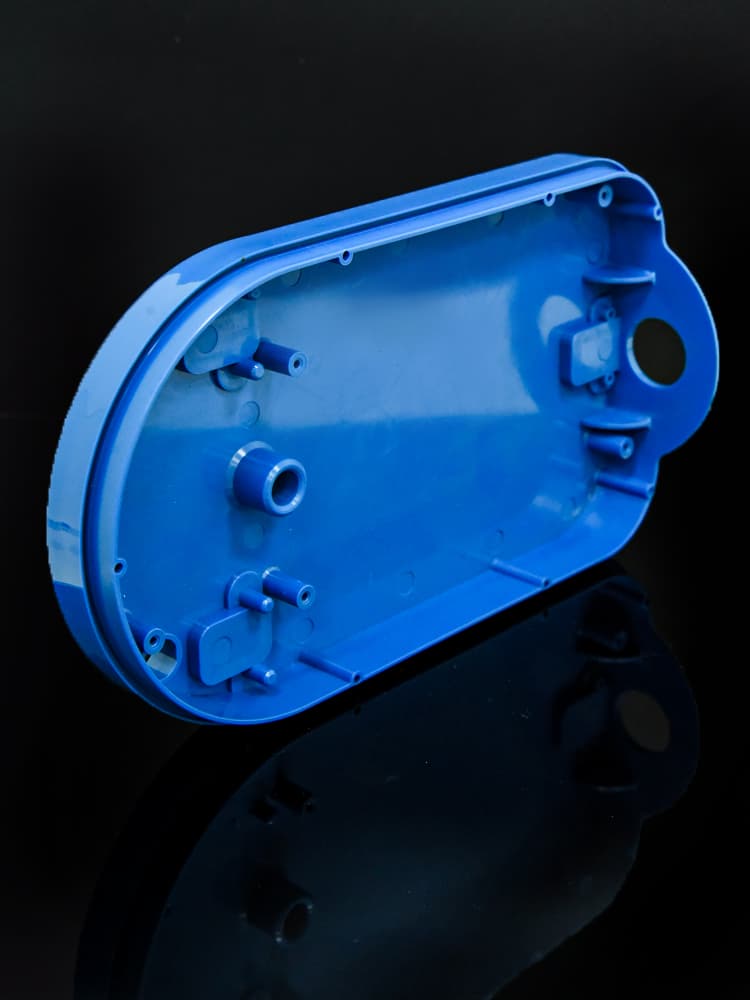

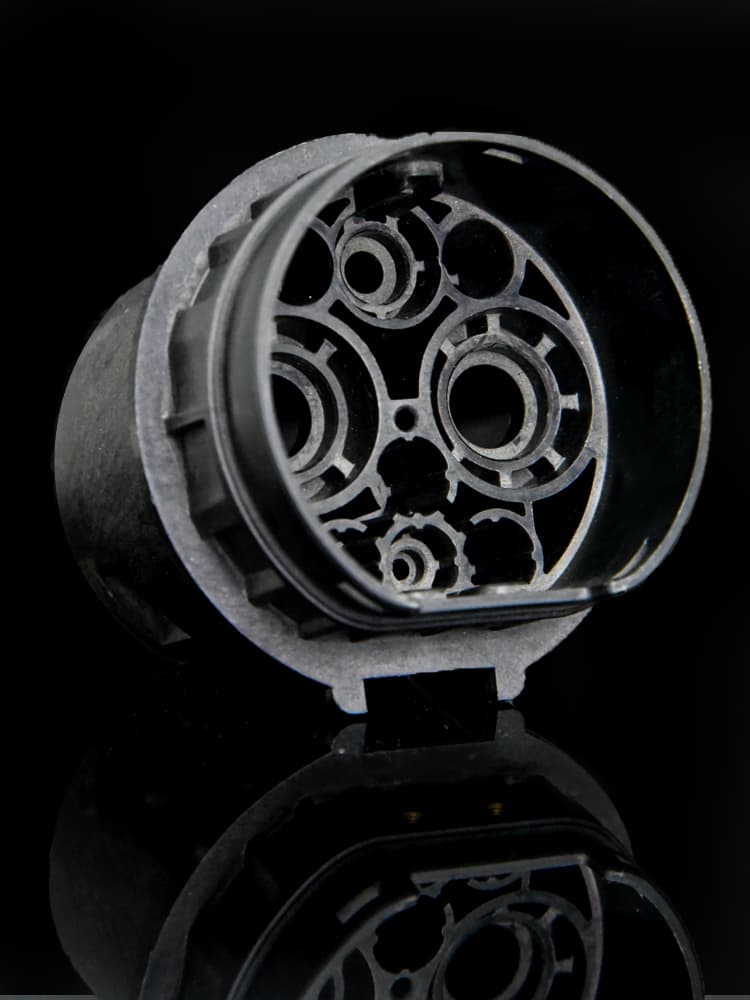

CNC Plastic Parts Case Study

Plastic Selection Guide-Industry

| Industry | Material Recommendation | Materials Characteristics | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Consumer Electronics, Electronics | ABS, PEI, PBT, PPS, PETP, G10, White Nylon | High-temperature resistance, excellent chemical stability, good electrical properties | |||||||||||

| Automotive | ABS, PP, PBT, PA6G, POM, white Nylon | High strength, wear resistance, good chemical resistance | |||||||||||

| Aerospace & Aviation | PEI, PTFE, PCTFE, PEEK, Carbon Fiber Plate | High-performance plastic, high mechanical strength, excellent chemical resistance | |||||||||||

| Chemical Industry | Hdpe, PPS, PTFE, PVDF, Green PP Rod | Chemical resistance, wear resistance, impact resistance, heat resistance | |||||||||||

| Machinery, Industrial Machinery | PA6G, Nylon MoS2, PETP, POM | Wear resistance, high strength | |||||||||||

| Construction | PVDF, PVC Grey, Transparent Acrylic | Good chemical resistance, wear resistance, high rigidity, impact resistance | |||||||||||

| Food Processing | HDPE,UHMW Black, Food Grade PET | Wear resistance, high impact strength, chemical resistance | |||||||||||

| Medical | PC, PCTFE, PEEK, Green PP Rod | Strong chemical resistance, excellent chemical stability, high impact strength | |||||||||||

| Packaging | PE, PP, UHMW Black | Lightweight, wear resistance, strong chemical resistance | |||||||||||

Plastic Selection Guide-Properties

| Properties | Material | Suitable for | ||||||

|---|---|---|---|---|---|---|---|---|

| Excellent mechanical properties | ABS | Household appliance housings, automotive parts, electronic product housings, etc. | ||||||

| PA6G | Bearings, gears, mechanical parts, etc. | |||||||

| PEI | Aerospace parts, medical devices, electronic components, etc. | |||||||

| PC | Car lamp covers, transparent parts, mechanical parts, etc. | |||||||

| Excellent corrosion resistance | HDPE | Chemical containers, pipelines, etc. | ||||||

| PVDF | Medical devices, electronic components, chemical processing equipment, etc. | |||||||

| PPS | Chemical containers, automotive parts, electronic product parts, etc. | |||||||

| Excellent high temperature resistance | PBT | Electronic components, automotive parts, household appliance parts, etc. | ||||||

| PA6G | Electronic components, automotive parts, aerospace parts, etc. | |||||||

| Excellent low temperature resistance | PE | Refrigerated food packaging, low-temperature pipelines, antifreeze containers, etc. | ||||||

| POM | Refrigerated food containers, low temperature parts, etc. | |||||||

| Excellent insulation | PA6G | Wire insulation, mechanical parts, insulation boards, etc. | ||||||

| Nylon | Electronic components, mechanical parts, insulation boards, etc. | |||||||

| Excellent transparency | PC | Car lamp covers, transparent containers, optical lenses, etc. | ||||||

| PET | Bottles, food packaging, transparent parts, etc. | |||||||

| Excellent wear resistance | PA6G | Conveyor belts, pulleys, wear-resistant parts, etc. | ||||||

| Nylon | Sliding bearings, gears, plastic shoemaking, etc. | |||||||

| G10 | Mechanical parts, insulation boards, electronic product parts, etc. | |||||||

How to Choose the Right Plastic Materials

Corrosion Resistance

PTFE: Almost unaffected by all chemicals.

PP: Good chemical resistance, excellent resistance to acids and alkalis.

PE: Excellent chemical resistance and impact resistance, suitable for various corrosive environments.

Outdoor Usage

PE: Good weather resistance and UV resistance, excellent chemical resistance, strong impact resistance.

PP: Good UV resistance, suitable for long-term outdoor use.

PC: Excellent weather resistance and impact resistance, high transparency.

Wear Resistance

POM: High wear resistance and self-lubricating properties, high mechanical strength.

UHMW-PE: High wear resistance and impact resistance, low friction coefficient.

PA: High wear resistance, good mechanical properties, and impact resistance.

Overall Performance

HDPE: Excellent weather resistance and impact resistance, suitable for various applications.

PET: Excellent mechanical properties and dimensional stability, suitable for precision parts.

G10: Excellent mechanical properties and electrical insulation, suitable for electronic parts.

Surface Treatment of Plastics

| Surface Finish | Surface Finish Description | CNC Parts Appearance | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Machining Surface Finishes | Parts are machined and deburred, with sharp edges chamfered. Visible machining marks and slight surface scratches. | Depends on the material | |||||||||

| Polishing | A method to reduce surface roughness and achieve a bright, smooth surface. The polishing process ranges from Ra 0.8 to Ra 0.1. | Achieves a smooth surface or mirror finish, also used for matte finish | |||||||||

| Sandblasting | Uses compressed air to propel abrasive material onto the surface for cleaning or grinding. | Can be matte, semi-gloss, or glossy, usually without specific color | |||||||||

| PVD | A thin film of metal, metal compounds, or ceramics is deposited on the surface to enhance hardness, corrosion resistance, and aesthetics. | Various colors | |||||||||

| Titanium Nitride Coating | A layer of titanium nitride is deposited to improve hardness and wear resistance. | Gold, black | |||||||||

| Chromium Nitride Coating | Chromium nitride is deposited onto the surface to enhance hardness and wear resistance. | Silver | |||||||||

| Powder Coating | Fine powders of pigment and resin are sprayed onto the surface to form a uniform coating, providing corrosion resistance, wear resistance, and decorative effects. | Various colors (depends on powder color) | |||||||||

| Painting | Liquid paint is applied to the surface to provide protection and decoration. | Various (depends on paint color) | |||||||||

| Laser Marking | A laser beam create high-precision markings or engravings on the surface. | Various (depends on material) | |||||||||

| Heat Transfer Printing | Patterns are transferred from transfer paper to plastic using heat and pressure. | Can achieve complex patterns and color effects | |||||||||

| UV Treatment | UV curing technology is used to treat plastic surfaces, enhancing their wear resistance, chemical resistance, and weather resistance. | Smoother and more even | |||||||||

| Cleaning | Effectively eliminates grease, oil, and various contaminants from surfaces. | Free of dust and grease | |||||||||

Xielifeng Order Process of Plastic Parts

From quotation to delivery, we provide efficient and high-quality services, making manufacturing more convenient

01

Upload drawing

02

DFM Evaluation & Quote

03

Order Confirmtion & Production

04

Quality Inspection & Delivery