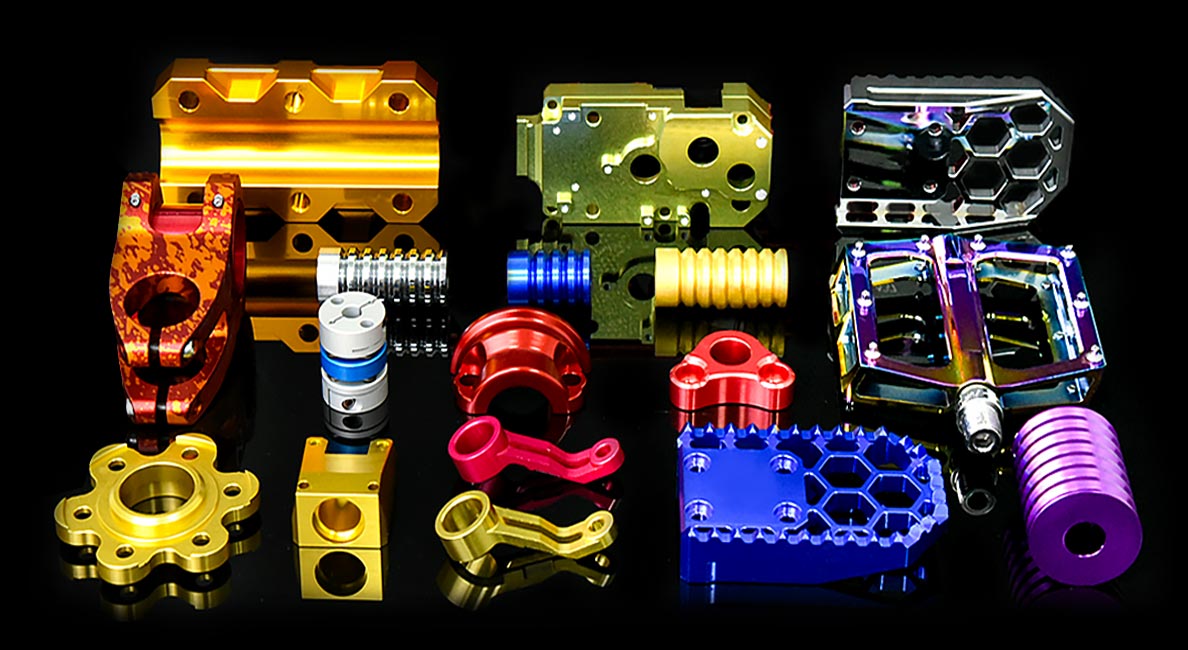

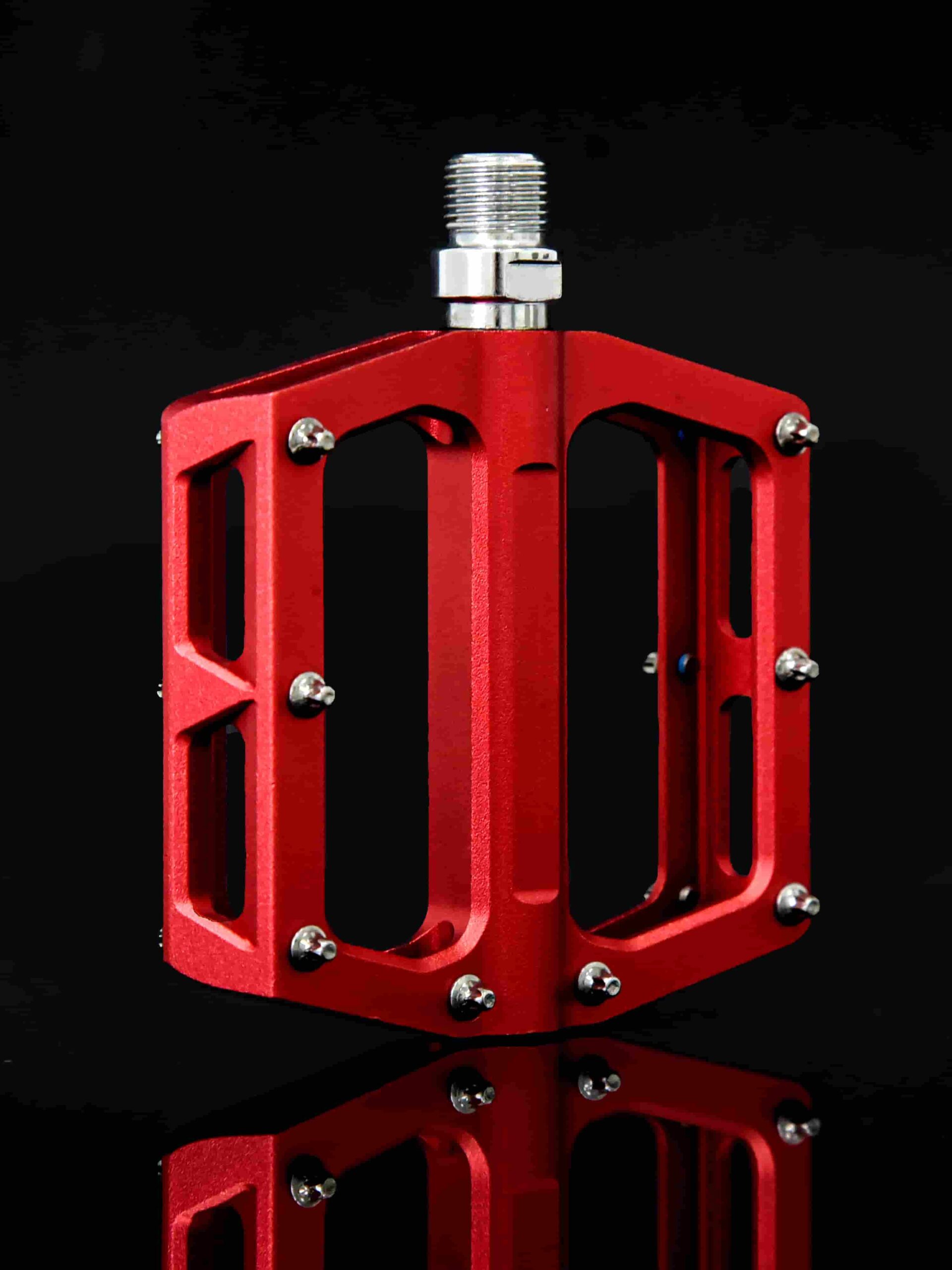

CNC Motorcycles & Bicycles Parts

±0.01mm Precision Custom Fit

30% Stronger, 50% Longer Lifespan

10,000+ Unique Parts Annually

All uploads are secure and confidential.* Learn More

IOS 9001

IOS 14001

About Our Capabilities

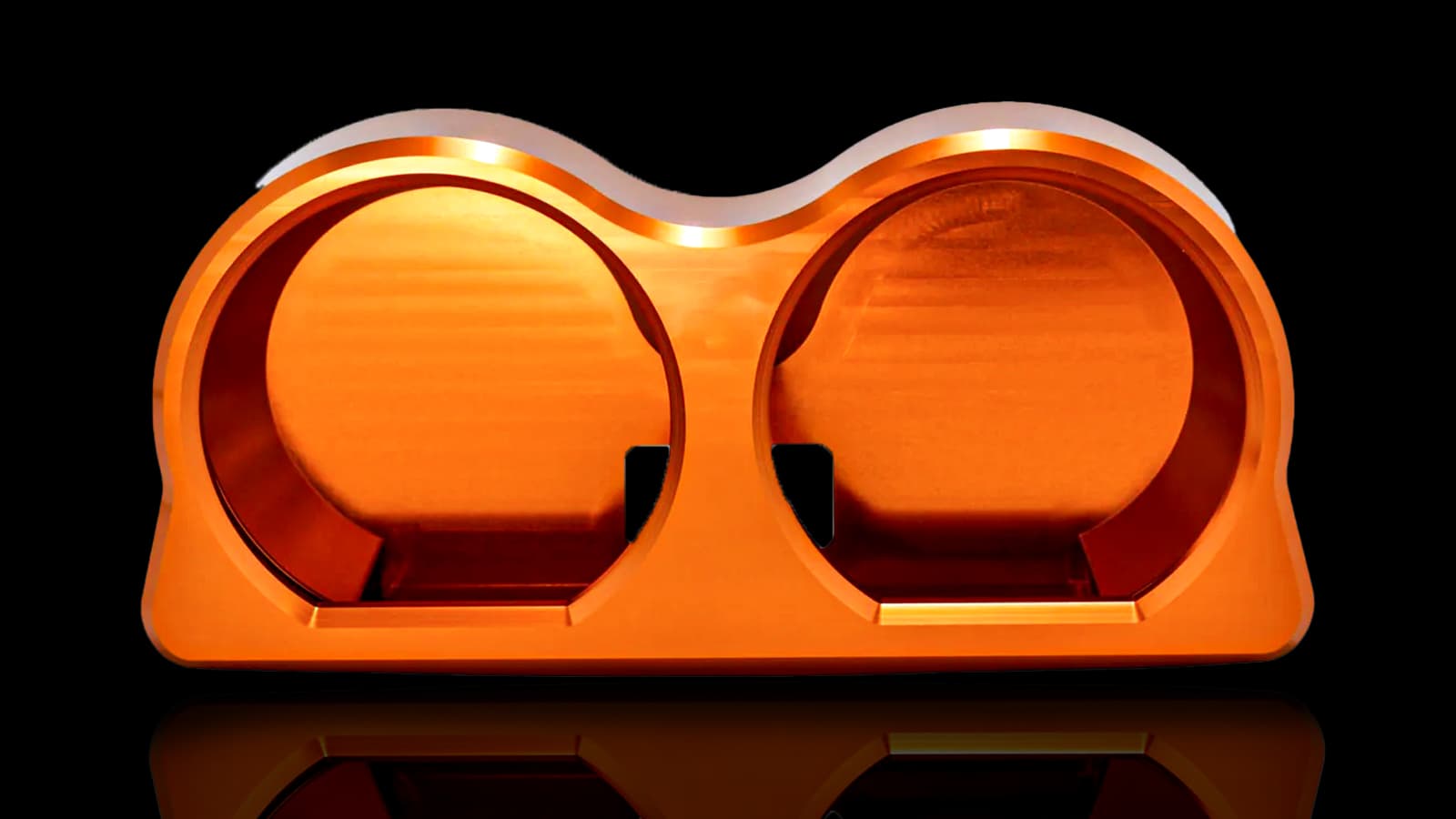

Personalized Customization and Perfect Fit

Lightweight Strength and Durability

Fast Delivery and Unique Aesthetics

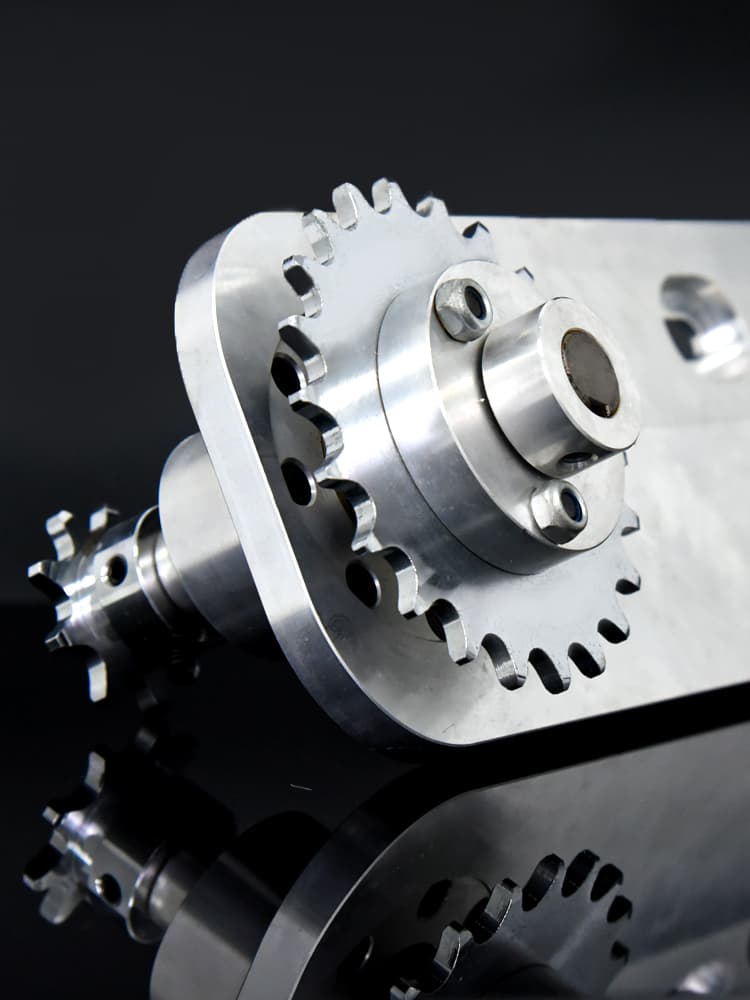

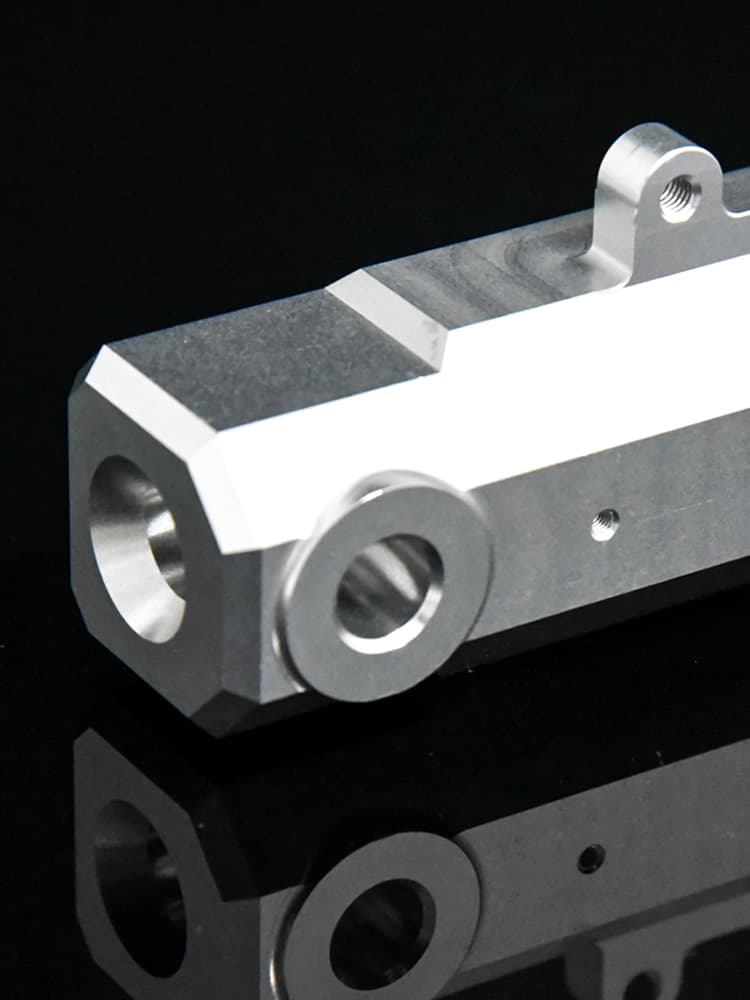

Personalized Customization and Perfect Fit

Custom-made according to customer designs, fully meeting specific requirements.

Utilizing CNC machining technology with precision up to ±0.01mm.

Successfully completed over 5,000 personalized custom orders.

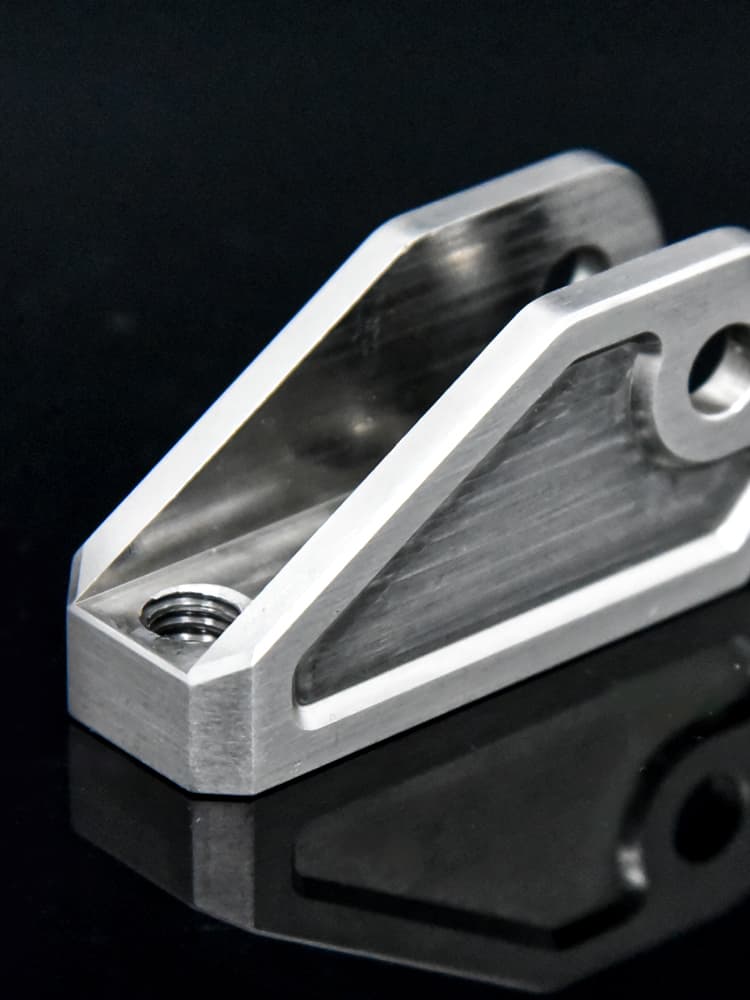

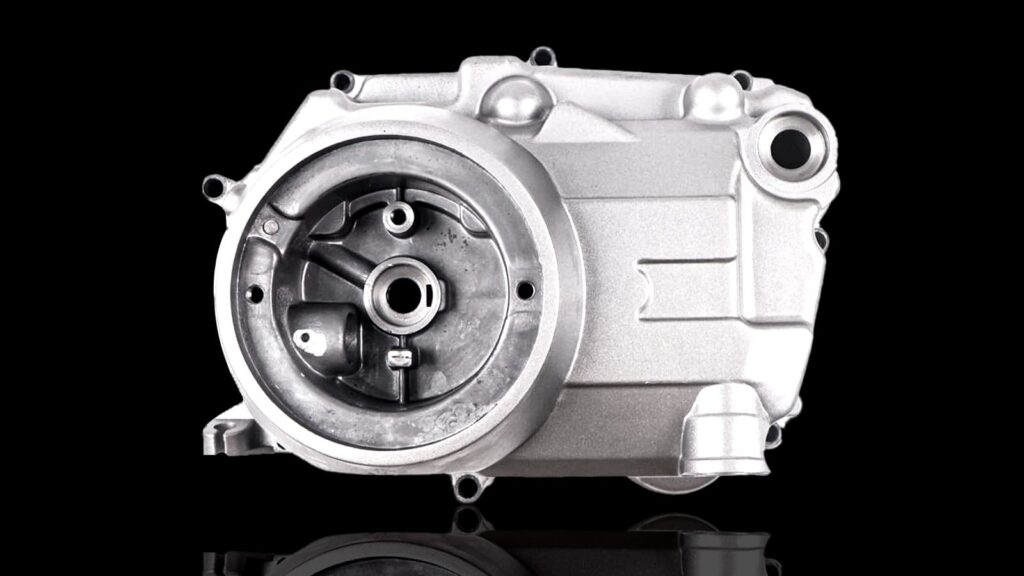

Lightweight Strength and Durability

Uses aerospace-grade aluminum alloys, carbon fiber, and other lightweight materials.

Special treatment increases part strength by 30% and extends lifespan by 50%.

Significantly enhances vehicle performance while reducing maintenance frequency by 20%.

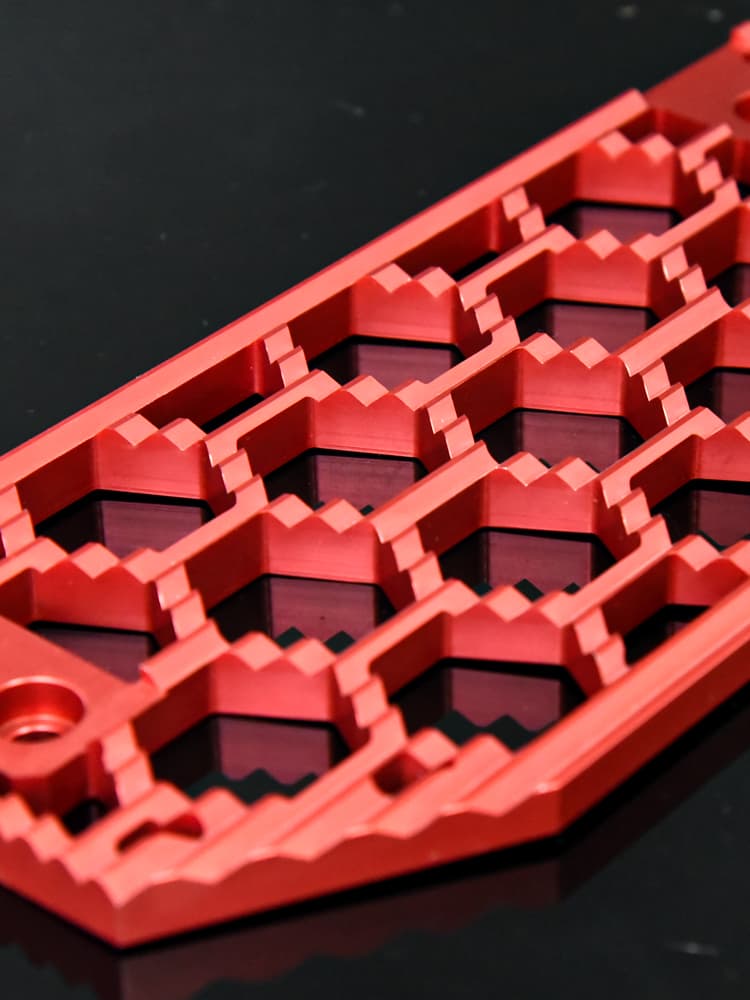

Fast Delivery and Unique Aesthetics

Equipped with 200 advanced machines, providing 24/7 production capability.

Completes custom orders within 5-7 days, ensuring timely delivery.

Delivers over 10,000 uniquely designed parts to global customers annually.

Materials for Motorcycles & Bicycles Parts

| Materials | Feature | Application Parts | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Aluminum | Lightweight, good strength, corrosion resistance, easy to process | Frames, wheels, handles, brake levers | ||||||||||||

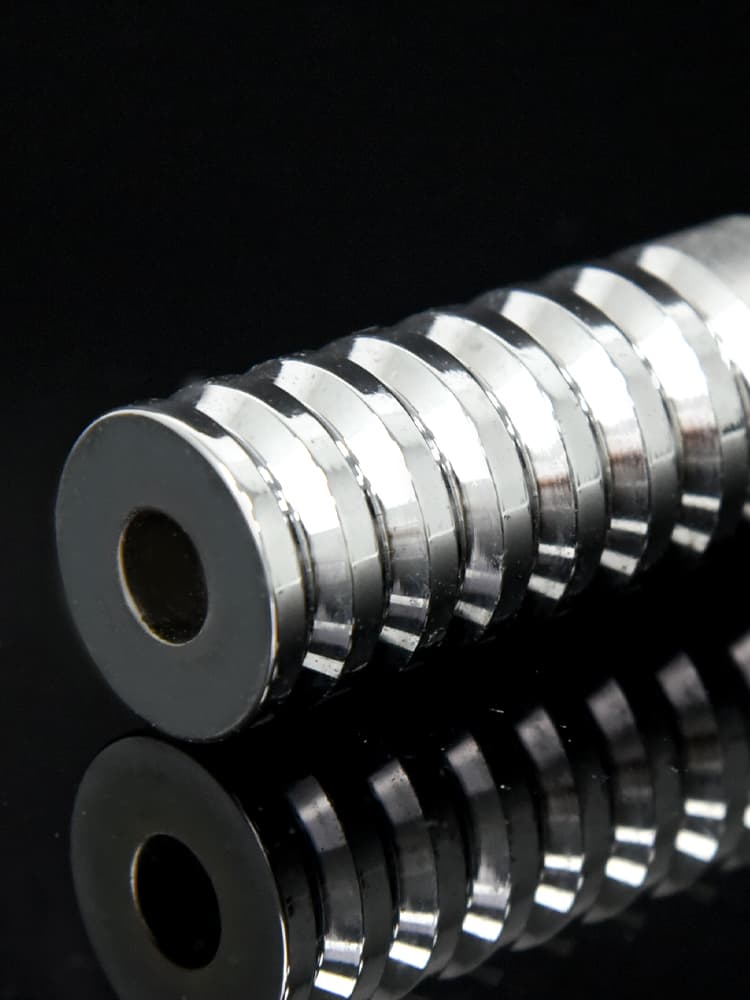

| Stainless Steel | Corrosion resistant, high strength, good heat resistance | Screws, nuts, bolts, exhaust pipes | ||||||||||||

| Steel | High strength, good wear resistance, high hardness | Gears, transmission shafts, vehicle supports | ||||||||||||

| Titanium | High strength, lightweight, corrosion-resistant, heat-stable | Brake calipers, exhaust pipes | ||||||||||||

| PC (Polycarbonate) | High impact resistance, transparency, good chemical resistance | Headlamp covers, car windows | ||||||||||||

| PP (Polypropylene) | Lightweight, chemical resistant, good impact resistance | Bumpers, fender liners | ||||||||||||

| PE (Polyethylene) | Good wear resistance, good heat resistance, low cost | Seats, tanks, protective covers | ||||||||||||

| Nylon | High strength, good wear resistance, good chemical resistance | Transmission belts, bearing sleeves | ||||||||||||

CNC Motorcycles & Bicycles Parts Post-Processing Capabilities

| Surface Treatment | Bicycle Parts | Motorcycle Parts | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Electroplating | Screws, nuts, bolts, metal strips | Screws, nuts, bolts, exhaust pipes | ||||||||||||

| Anodizing | Aluminum alloy frames, wheels | Aluminum alloy frames, engine casings | ||||||||||||

| Painting | Frames, fenders, mudguards | Frames, fenders, covers | ||||||||||||

| Sand blasting | Frames, metal part surfaces | Engine casings, metal part surfaces | ||||||||||||

| Heat Treatment | Cranksets, frames | Bent metal parts, gears | ||||||||||||

| Electrophoretic | Frames, metal fenders, metal mudguards | Engine casings, frames | ||||||||||||

Precision Motorcycles & Bicycles Parts Case Study

Our Partners

Expert Guidance on Motorcycles & Bicycles Product Development

Engineer Daniel, 12 years of experience in machining custom parts for the motorcycle and bicycle industry. Specialized in lightweight component machining and high-precision assemblies, familiar with industry standards and the performance requirements of high-end brands such as Harley-Davidson. Daniel sorts out relevant professional knowledge for your reference

What are the key factors when selecting materials for motorcycle and bicycle parts?

We consider lightweight, strength, and corrosion resistance. For example, 6061 and 7075 aluminum alloys are commonly used for frames, while titanium alloys are selected for parts requiring high strength-to-weight ratios. Carbon fiber is ideal for performance-driven applications but requires specialized machining techniques.

What surface treatments do you recommend for bicycle and motorcycle components?

We recommend anodizing for aluminum parts to enhance corrosion resistance and powder coating for durable, aesthetic finishes. For metal components that require extra wear resistance, we offer PVD coating. These treatments not only improve durability but also add aesthetic value.

How do you ensure proper fit for custom parts like cranksets and brake components?

We work closely with clients to align with their CAD designs and specification drawings. After machining, each part undergoes pre-assembly testing to verify fit and function. We also offer adjustment services for prototypes, ensuring smooth integration in the final assembly.

What are the main challenges when machining lightweight components for bicycles and motorcycles?

Lightweight materials such as titanium and carbon fiber can cause rapid tool wear and require precise control of cutting parameters. Maintaining structural integrity while reducing material weight is a delicate balance. Our engineers use optimized cutting strategies and high-quality tools to overcome these challenges.

How do you handle rush orders or urgent projects?

We prioritize rush orders by optimizing our production schedules and maintaining flexible machining capacity. With in-house stock of common materials and rapid prototyping capabilities, we ensure fast turnaround times. Close communication with clients helps us meet tight deadlines without compromising quality.

How Xielifeng Works

From quotation to delivery, we provide efficient, high-quality services, making manufacturing more convenient.

01

Upload drawing

CAD files: 2D: DXF | DWG | PDF 3D: STP | STEP |IGS | IGES| X_T | SLDPRT

02

DFM Evaluation & Quote

- Drawing review

- Process analysis

- Material inspection

- Feasibility proposal

- Cost estimation

03

Order Confirmtion & Production

- Sample processing

- Sample quality inspection

- Customer confirmation

- Mass production plan

04

Quality Inspection & Delivery

- Raw material inspection

- First piece inspection

- Process inspection

- Final inspection

- Inspection report