CNC Machining Materials

Explore our vast selection of materials tailored for precision machining. Each material is chosen for its quality, durability, and suitability for various industries.

200+ Materials

24/7 Technical Support

25 Years of Experience in CNC

97.8% Customer Satisfaction

All uploads are secure and confidential.* Learn More

ISO 9001

ISO 14001

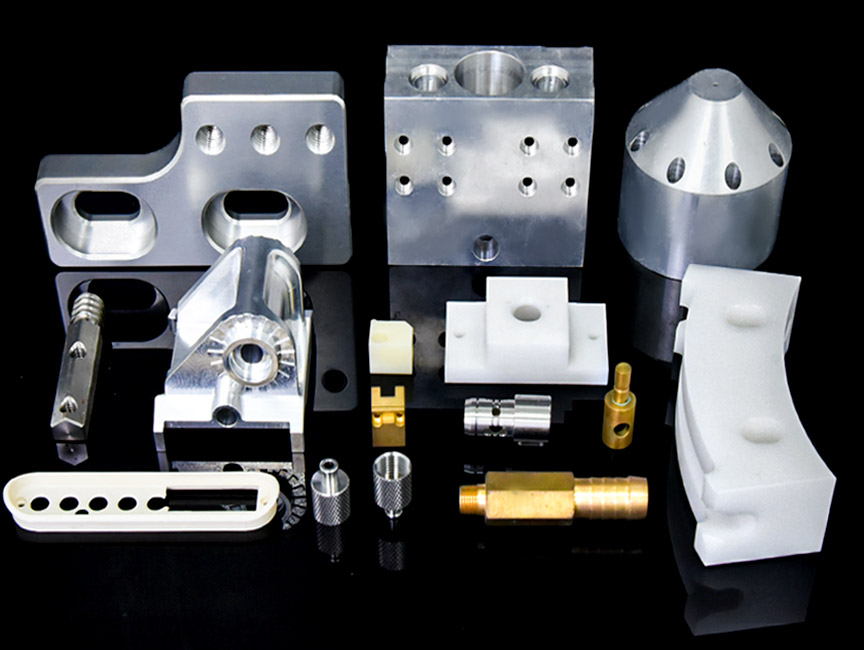

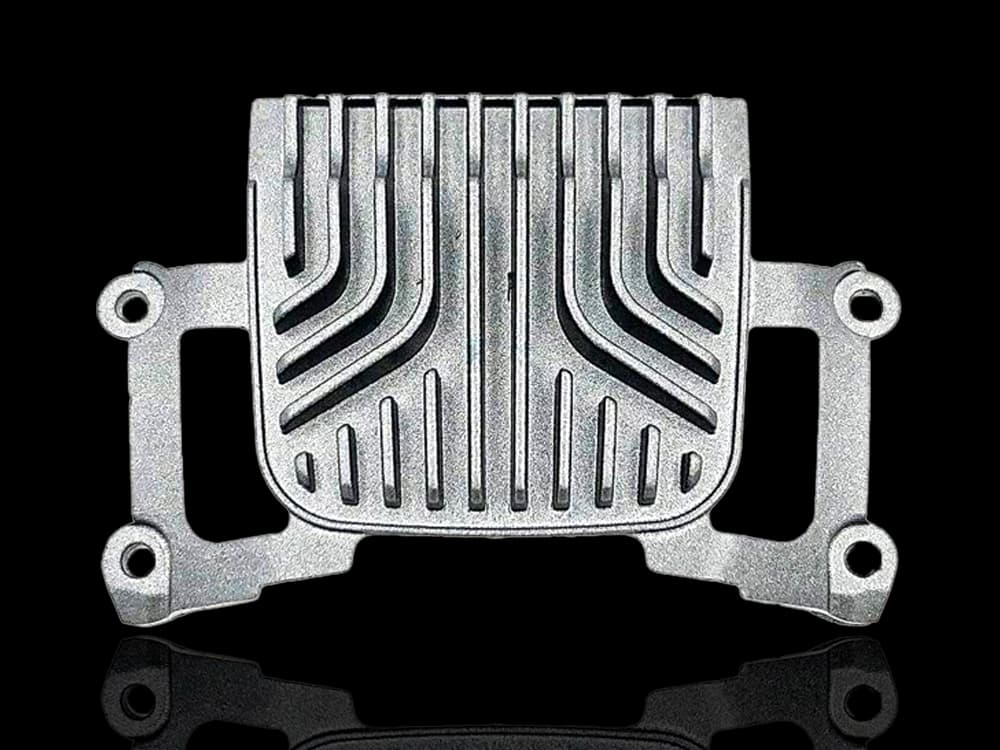

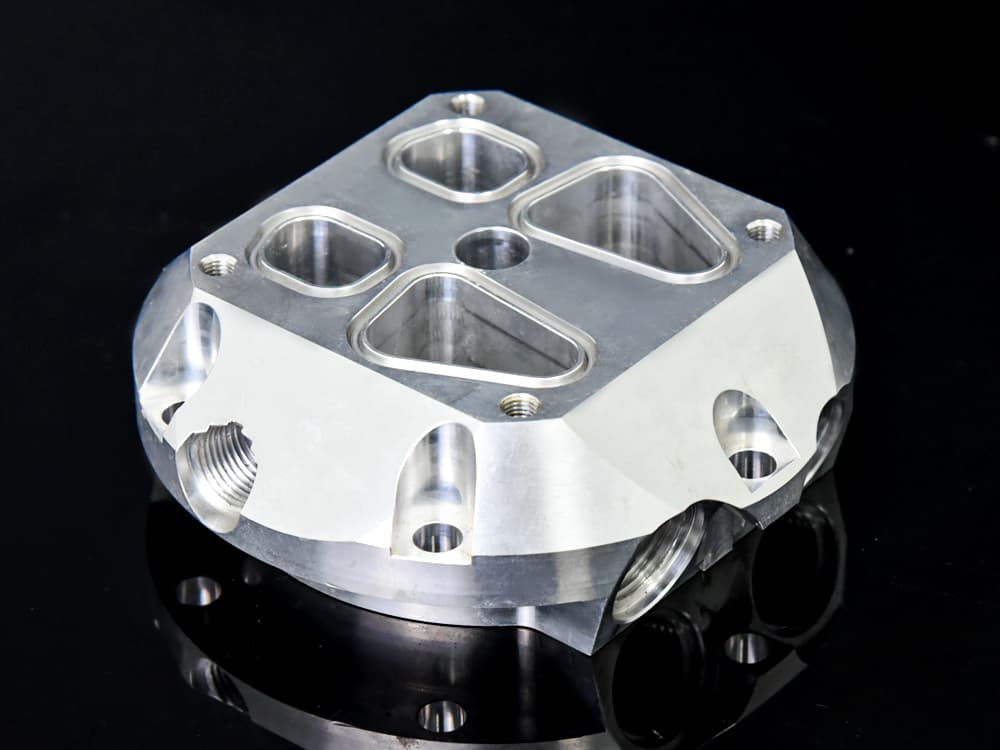

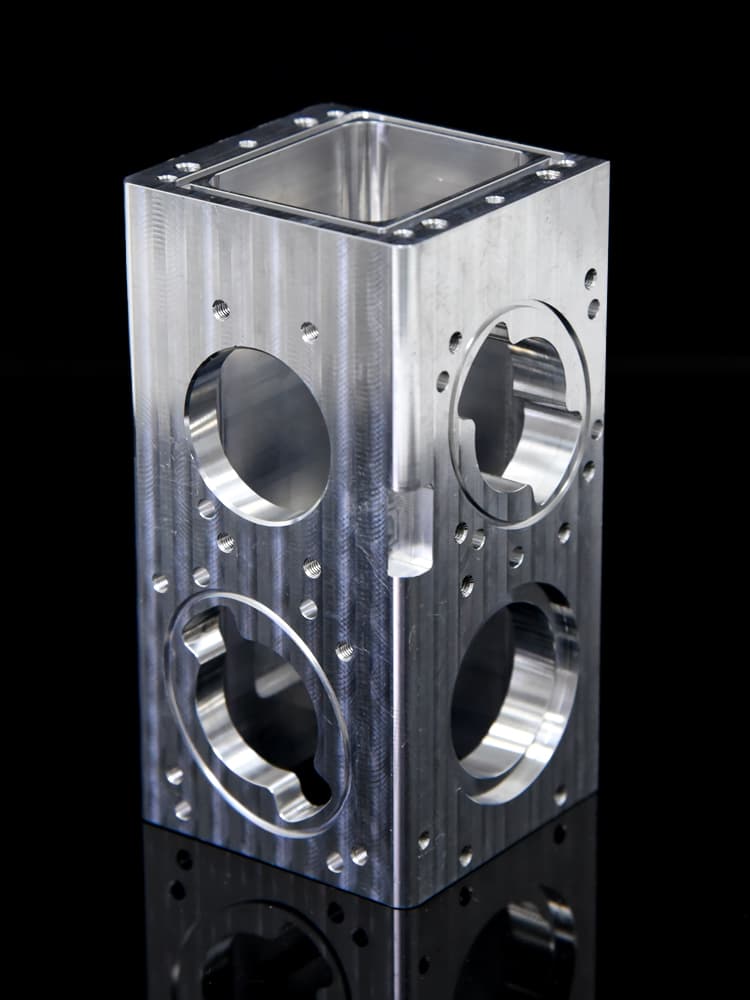

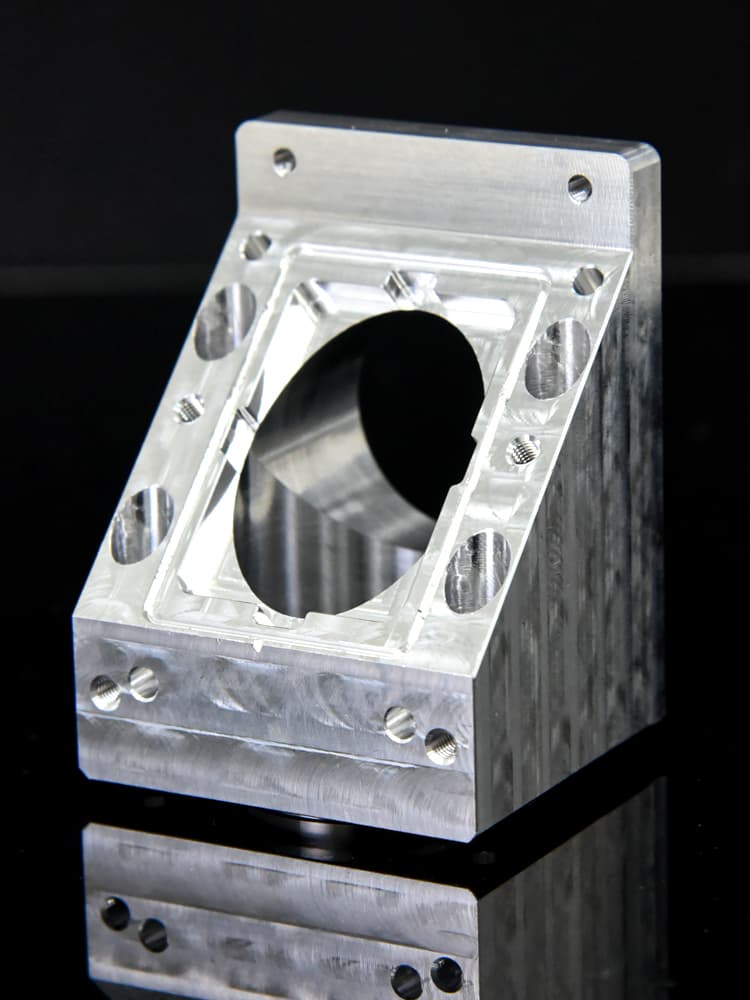

CNC Metal Parts

CNC Plastic Parts

CNC Machining Materials Selection by Features

Metal Material

Aluminum 6061

√ Good machinability, easy to cut and shape, the most widely used aluminum alloy material.

√ Commonly used in aerospace, automotive parts, and consumer electronics housings.

Stainless Steel 304

√ Good machinability, suitable for most conventional machining techniques.

√ Used in food processing equipment, architectural decoration, and medical devices.

Brass C360

√ Easy to machine, provides good machinability with tight tolerances and smooth surfaces.

√ Commonly used in precision instruments, electrical components, and decorative items.

Plastic Material

Polyether Ether Ketone (PEEK)

√ Highly machinable, endures high temperatures and chemicals, perfect for complex shapes.

√ Used in aerospace, medical devices, and automotive industries for high-performance components.

Nylon 6/6

√ Excellent machinability, high friction and chemical resistance, can be machined using various techniques.

√ Used for manufacturing gears, bearings, and other industrial machinery parts.

Polyoxymethylene (POM)

√ Excellent machinability, high mechanical strength, and high dimensional stability.

√ Widely used for manufacturing precision gears, bearings, sliding parts, and moving parts.

Metal Material

Aluminum 6061-T6

√ Good mechanical properties and corrosion resistance, but may be limited in marine environments.

√ Commonly used in aerospace parts, automotive components, structural frames.

Stainless Steel 316L

√ Excellent resistance to pitting and crevice corrosion.

√ Commonly used in chemical equipment, medical devices, marine engineering, and other high-corrosion-resistant environments.

Titanium Alloy Ti-6Al-4V

√ High strength and excellent corrosion resistance. Highly stable in almost all environments.

√ Commonly used in aerospace components, medical implants, marine engineering parts.

Plastic Material

Polyvinylidene Fluoride (PVDF)

√ Excellent chemical corrosion resistance and mechanical properties.

√ Commonly used in chemical processing equipment, piping systems, pumps, and valves.

Polytetrafluoroethylene (PTFE)

√ A modified PTFE material offering higher mechanical strength and high-temperature performance.

√ Commonly used in seals, gaskets, insulation materials, and corrosion-resistant linings.

Polyether Ether Ketone (PEEK)

√ Excellent chemical corrosion resistance, mechanical strength, and high-temperature performance.

√ Commonly used in aerospace components, automotive parts, medical devices, and chemical equipment.

Metal Material

Carbon Steel (AISI 1018)

√ Low carbon steel with good machinability and toughness and low cost.

√ Used for machine parts, gears, shafts, and bolts.

Aluminum Alloy 6061-T6

√ Excellent machinability, corrosion resistance, and relatively low cost.

√ Used in structural components, automotive parts, aerospace parts, and consumer electronics.

Brass (C36000)

√ Free machining brass with excellent machinability and corrosion resistance.

√ Precision instruments, valves, fittings, and electrical components.

Plastic Material

Polyoxymethylene (POM) Delrin® 150

√ High rigidity and strength engineering plastic with excellent machinability.

√ Commonly used in precision parts, gears, bearings, and automotive components.

Nylon (PA) Nylon 6/6

√ Engineering plastic with good mechanical properties and wear resistance.

√ Used for gears, pulleys, mechanical parts, and bearings.

Acrylonitrile Butadiene Styrene (ABS)

√ Engineering plastic with good mechanical properties and cost-effectiveness, easy to process.

√ Commonly used in automotive parts, appliance housings, and electronic device enclosures.

Metal Material

Titanium Alloy (Ti-6Al-4V)

√ Excellent fatigue resistance, lightweight, high strength, and corrosion resistance.

√ Aerospace components, medical implants, marine engineering parts.

Stainless Steel (17-4PH)

√ Good fatigue resistance, high strength, and corrosion resistance.

√ Aerospace components, chemical processing equipment, medical instruments.

Aluminum Alloy (7075-T6)

√ Excellent fatigue resistance, high strength, and good machinability.

√ Aerospace structural components, racing parts, bicycle frames.

Plastic Material

Polyether Ether Ketone (PEEK)

√ Extremely high fatigue resistance, high-temperature resistance, and chemical corrosion resistance.

√ Aerospace components, automotive parts, medical devices.

Polyamide (PA) Nylon 6/6

√ Good fatigue resistance, high strength, and wear resistance.

√ Gears, pulleys, mechanical parts, and bearings.

Polycarbonate (PC)

√ Good fatigue resistance, high impact strength, and transparency.

√ Safety protective equipment, optical lenses, electronic housings.

Metal Material

Aluminum Alloy (6061-T6)

√ Excellent dimensional stability, good machinability, and corrosion resistance.

√ Aerospace structural components, automotive parts, mechanical components.

Stainless Steel (303)

√ Good dimensional stability, high strength, and corrosion resistance.

√ Precision instrument parts, bolts, nuts, and bearings.

Carbon Steel (AISI 1045)

√ Good dimensional stability, high strength, easy to machine and heat treat.

√ Shafts, gears, connecting rods, and mechanical parts.

Plastic Material

Polycarbonate (PC)

√ Good dimensional stability, high impact strength, and transparency.

√ Optical lenses, safety protective equipment, electronic housings.

Polyoxymethylene (POM)

√ Excellent dimensional stability, mechanical strength, and wear resistance.

Applications: Precision parts, gears, bearings, and automotive components.

Nylon (PA) Nylon 6/6

√ Good dimensional stability, high strength, and wear resistance.

√ Gears, pulleys, mechanical parts, and bearings.

Metal Material

Aluminum Alloy (6061-T6)

√ Good ductility, excellent machinability, and corrosion resistance.

√ Aerospace structural components, automotive parts, construction materials.

Brass (C26000)

√ Excellent ductility and good machinability, easy to form.

√ Precision instruments, valves, fittings, and electrical components.

Copper (C11000)

√ Extremely high ductility and electrical conductivity, easy to process and form.

√ Electrical components, piping, radiators.

Metal Material

Copper (C11000)

√ Extremely high electrical and thermal conductivity, good ductility, and corrosion resistance.

√ Electrical components, conductive tracks, distribution equipment.

Brass (C36000)

√ Good electrical conductivity, corrosion resistance, and excellent machinability.

√ Precision instruments, connectors, valves, fittings, and electrical components.

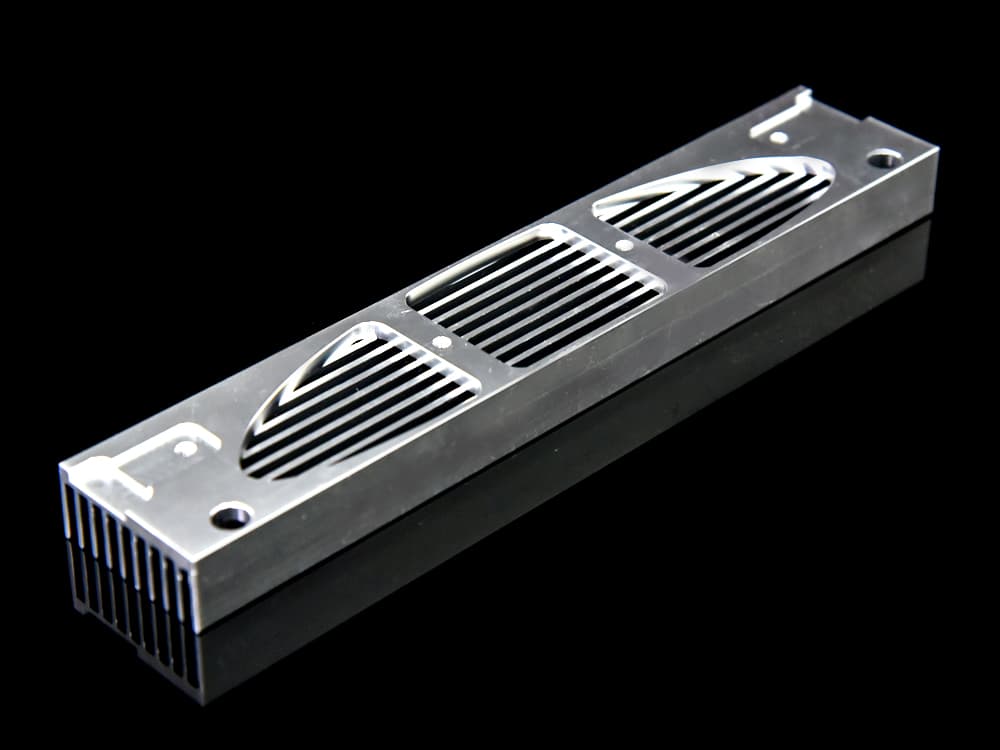

Aluminum Alloy (6063-T5)

√ Good electrical conductivity, lightweight, and high corrosion resistance.

√ Conductive busbars, cables, electronic heat sinks.

Plastic Material

Polytetrafluoroethylene (PTFE)

√ Excellent electrical insulation properties, high-temperature resistance, and chemical corrosion resistance.

√ Electrical insulation materials, seals, chemical equipment linings.

Polyoxymethylene (POM)

√ Good electrical insulation properties, mechanical strength, and wear resistance.

√ Precision parts, gears, bearings, and electrical insulation components.

Polyamide (PA) Nylon 6/6

√ Good electrical insulation properties, high strength, and wear resistance.

√ Gears, pulleys, mechanical parts, and electrical insulation components.

Metal Material

Stainless Steel (304)

√ Excellent high-temperature resistance and corrosion resistance, non-combustible, high mechanical strength.

√ Building structural components, kitchen equipment, chemical processing equipment.

Titanium Alloy (Ti-6Al-4V)

√ Excellent high-temperature resistance and mechanical strength, lightweight, non-combustible.

√ Aerospace components, medical implants, high-temperature environment applications.

Aluminum Alloy (6061-T6)

√ Good mechanical properties and high-temperature resistance, non-combustible.

√ Aerospace structural components, automotive parts, construction materials.

Plastic Material

Polycarbonate (PC)

√ Excellent flame resistance, high impact strength, and transparency.

√ Safety protective equipment, optical lenses, electronic housings.

Polyether Ether Ketone (PEEK)

√ Excellent flame resistance, high-temperature resistance, and mechanical strength.

√ Aerospace components, automotive parts, medical devices.

Polyvinylidene Fluoride (PVDF)

√ Excellent flame resistance, chemical corrosion resistance, and mechanical strength.

√ Chemical processing equipment, electrical insulation, piping systems.

Metal Material

Stainless Steel (310S)

√ Excellent high-temperature resistance, withstanding up to 1150°C, and good corrosion resistance.

√ High-temperature furnace components, combustion chambers, heat exchangers.

Titanium Alloy (Ti-6Al-4V)

√ Excellent high-temperature resistance and mechanical strength, lightweight, withstanding up to 700°C.

√ Aerospace components, engine parts, high-temperature environment applications.

Nickel Alloy (Inconel 718)

√ Exceptional high-temperature resistance and oxidation resistance, withstanding up to 700°C, and excellent mechanical strength.

√ Turbine engine parts, nuclear reactor components, aerospace structural components.

Plastic Material

Polyether Ether Ketone (PEEK)

√ Excellent high-temperature resistance, capable of long-term use at temperatures up to 260°C, along with high mechanical strength and chemical corrosion resistance.

√ Aerospace components, automotive parts, medical devices.

Polyimide (PI)

√ Outstanding high-temperature resistance, usable at temperatures up to 400°C, with good electrical insulation properties.

√ Electronic insulation materials, high-temperature seals, aerospace applications.

Metal Material

D2 Tool Steel

√ High-carbon, high-chromium alloy tool steel with excellent wear resistance and high hardness.

√ Molds, cutting tools, knives, bearing components.

Alloy Steel 42CrMo

√ High strength, high toughness, good hardenability, and excellent wear resistance.

√ Gears, shafts, connectors, fasteners, and other high-strength parts.

440C Stainless Steel

√ High-carbon stainless steel with very high hardness and wear resistance, along with good corrosion resistance.

√ Bearings, knives, valve components, molds.

Plastic Material

Polyoxymethylene (POM)

√ Excellent wear resistance, high mechanical strength, low friction coefficient, and chemical resistance.

√ Precision parts, gears, bearings, sliding components.

Polyamide (PA) Nylon 6/6

√ Good wear resistance and mechanical strength, chemical resistance, and low water absorption.

√ Gears, pulleys, mechanical parts, bearings, bushings.

Polyether Ether Ketone (PEEK)

√ Outstanding wear resistance, high mechanical strength, high-temperature resistance, and chemical resistance.

√ Aerospace components, automotive parts, medical devices, sliding components, valve seats.

Metal Material

Aluminum Alloy (6061-T6)

√ Good mechanical properties, corrosion resistance, lightweight, and easy to machine.

√ Aerospace structural components, automotive parts, construction materials.

Density: 2.70 g/cm³

Magnesium Alloy (AZ91D)

√ Extremely lightweight, good mechanical properties, and corrosion resistance.

√ Automotive parts, electronic product housings, aerospace components.

Density: 1.81 g/cm³

Titanium Alloy (Ti-6Al-4V)

√ High strength, lightweight, excellent corrosion resistance, and good high-temperature performance.

√ Aerospace components, medical implants, sports equipment.

Density: 4.43 g/cm³

Plastic Material

Polyethylene (PE)

√ Lightweight, high flexibility, chemical corrosion resistance, and impact resistance.

√ Soft packaging, films, containers, pipes.

Density: 0.91 – 0.94 g/cm³

Polypropylene (PP)

√ Lightweight, good mechanical properties, and chemical corrosion resistance.

√ Packaging materials, containers, fibers, automotive parts.

Density: 0.89 – 0.92 g/cm³

Polycarbonate (PC)

√ Good mechanical properties, high impact strength, transparency, and lightweight.

√ Safety protective equipment, optical lenses, electronic housings.

Density: 1.20 – 1.22 g/cm³

Metal Material

Stainless Steel (316L)

√ Excellent UV resistance, corrosion resistance, and high strength. Suitable for long-term outdoor use without UV damage.

√ Precision mechanical parts, marine equipment, outdoor construction components, chemical equipment parts.

Aluminum Alloy (6061-T6)

√ Good UV resistance, corrosion resistance, and lightweight. Suitable for outdoor applications, maintaining performance under prolonged sunlight exposure.

√ Precision instrument housings, aerospace structural components, automotive parts, construction materials.

Titanium Alloy (Ti-6Al-4V)

√ High strength, excellent UV resistance, and good corrosion resistance. Ideal for long-term outdoor exposure.

√ Precision aerospace components, outdoor sports equipment, medical devices, building facades.

Plastic Material

Polyoxymethylene (POM) Delrin® UV

√ Excellent UV resistance, high mechanical strength, low friction coefficient, and chemical resistance. Designed for outdoor use, it withstands prolonged UV exposure without degradation.

√ Precision gears, sliding components, bearings, outdoor instrument parts.

Polyether Ether Ketone (PEEK UV)

√ Excellent UV resistance, high mechanical strength, high temperature resistance, and chemical resistance. Maintains performance under high UV exposure.

√ Precision instrument parts, automotive components, medical devices, outdoor application parts.

Polyamide (PA) Nylon 6/6 UV Stabilized

√ Good UV resistance, wear resistance, and mechanical strength. Enhanced with UV stabilizers to withstand prolonged UV exposure without degradation.

√ Precision gears, sliding components, mechanical parts, outdoor equipment parts.

Metal Material

Aluminum Alloy (5052-H32)

√ Good noise reduction and corrosion resistance, lightweight, suitable for manufacturing soundproofing and vibration-damping components.

√ Car body panels, machinery equipment housings, soundproof walls.

Stainless Steel (304)

√ Good noise reduction and corrosion resistance, high mechanical strength, suitable for manufacturing high-strength soundproof components.

√ Machinery equipment housings, pipe soundproof sleeves, building soundproof materials.

Nickel Alloy (Inconel 625)

√ Excellent noise reduction, high-temperature resistance, and corrosion resistance, suitable for soundproofing applications in extreme environments.

√ Turbine engine soundproof covers, high-temperature soundproof components, aerospace noise reduction parts.

Plastic Material

Polyurethane (PU)

√ Excellent noise reduction and vibration absorption properties, with good flexibility and wear resistance. Suitable for manufacturing soundproofing and vibration-damping parts.

√ Soundproof panels, seals, vibration-damping pads, precision mechanical components.

Polyethylene (PE)

√ Good noise reduction properties, impact resistance, and chemical resistance. Lightweight and flexible, suitable for manufacturing various noise reduction parts.

√ Soundproof mats, pipe soundproof sleeves, noise-reduction components for machinery.

Polyester Fiber (PET Fiber)

√ Excellent sound absorption and noise reduction properties, with good wear resistance and chemical resistance. Suitable for manufacturing high-efficiency sound-absorbing materials.

√ Sound-absorbing panels, soundproof materials, precision mechanical components, automotive interiors.

Metal Material

Stainless Steel (304)

√ Excellent compressive strength, corrosion resistance, and high strength. Suitable for applications in high-strength and high-pressure environments.

√ High-pressure vessels, structural components, pump and valve parts, building components.

Aluminum Alloy (7075-T6)

√ Extremely high compressive strength, strength, and hardness, while being lightweight. Suitable for high-strength and high-load applications.

√ Aerospace structural components, automotive parts, high-pressure vessels.

Titanium Alloy (Ti-6Al-4V)

√ High strength, excellent compressive strength, and corrosion resistance, while being lightweight. Suitable for high-pressure and high-strength applications.

√ High-pressure vessels, aerospace components, medical devices, structural components.

Plastic Material

Polyether Ether Ketone (PEEK)

√ Excellent compressive strength, high mechanical strength, high-temperature resistance, and chemical resistance. Capable of long-term use in high-pressure environments without deformation.

√ High-pressure seals, aerospace components, automotive parts, medical devices.

Polyoxymethylene (POM)

√ Good compressive strength, high mechanical strength, and wear resistance. Ideal for applications demanding exceptional strength and rigidity.

√ Precision gears, bearings, valve components, sliding parts.

Polyamide (PA) Nylon 6/6

√ Good compressive strength, mechanical strength, and wear resistance. Suitable for high-stress and high-load applications.

√ Gears, pulleys, mechanical parts, bearings, structural components.

Plastic Material

Polycarbonate (PC)

√ Excellent transparency, high impact strength, and heat resistance. Suitable for applications requiring high clarity and strength.

√ Optical lenses, safety protective equipment, electronic housings, automotive lamp covers.

Acrylic (PMMA)

√ Exceptional transparency, optical properties, and weather resistance. Lighter and more impact-resistant than glass.

√ Transparent covers, displays, protective shields, optical components.

Polyester (PET)

√ Good transparency and high mechanical strength, with excellent chemical resistance.

√ Optical films, electronic displays, packaging materials, optical elements.

Metal Material

Stainless Steel (304)

√ Excellent weldability and corrosion resistance, with minimal risk of cracking and deformation after welding.

√ Building structural components, kitchen equipment, medical devices, chemical processing equipment.

Aluminum Alloy (6061-T6)

√ Good weldability, corrosion resistance, and high strength, retaining good mechanical properties after welding.

√ Aerospace structural components, automotive parts, construction materials, sports equipment.

Low Carbon Steel (AISI 1018)

√ Good weldability and machinability, with minimal risk of cracking after welding, and excellent mechanical properties.

√ Mechanical parts, structural components, automotive parts, piping systems.

Metal Material

Stainless Steel (316L)

√ Excellent corrosion resistance and mechanical strength, compliant with food contact safety standards. Extensively utilized in the food processing and pharmaceutical sectors.

√ Food processing equipment, storage tanks, piping, valves, tableware.

Aluminum Alloy (6061-T6) (Food Grade)

√ Good mechanical properties, corrosion resistance, lightweight, and compliant with food contact safety standards.

√ Food processing equipment, tableware, storage tanks, packaging materials.

Stainless Steel (304)

√ Good corrosion resistance and mechanical strength, compliant with food contact safety standards. Commonly employed in the food processing and pharmaceutical industries.

√ Food processing equipment, storage tanks, piping, valves, tableware.

Plastic Material

High-Density Polyethylene (HDPE, Food Grade)

√ Good chemical resistance, high strength, and excellent food contact safety. Compliant with FDA standards, suitable for food processing and packaging.

√ Food processing equipment parts, conveyor parts, bearings, sliding components.

Polypropylene (PP, Food Grade)

√ Good chemical resistance, high rigidity, and high-temperature resistance. Compliant with FDA standards, suitable for food contact applications.

√ Food processing equipment parts, piping, valves, bushings, seals.

Polyoxymethylene (POM) Delrin® FG (Food Grade)

√ Excellent mechanical strength, wear resistance, and low friction coefficient, compliant with food contact safety standards.

√ Food processing equipment parts, gears, sliding components, bearings.

CNC Machining Materials Selection by Application Area

Motorcycles & Bicycles

Parts:

Frames, Wheel hubs, Swingarms

Recommended Materials:

AL6061, 1045 (Aluminum Alloy AL6061, Steel 1045)

Automotive

Parts:

Engine blocks, Body structures, Suspension components

Recommended Materials:

High-strength Steel, Aluminum Alloys

Electronics

Parts:

Connectors, Casings, Heat sinks

Recommended Materials:

Polycarbonate, ABS

New Energy

Parts:

Battery supports, Structural components, Motor housings

Recommended Materials:

Aluminum Alloys, Titanium Alloys

Household Appliance

Parts:

Motor casings, Control panels, Transmission gears

Recommended Materials:

Stainless Steel, Polycarbonate

Firefighting Equipment

Parts:

Nozzles, Valves, Couplings

Recommended Materials:

CuSn7Zn4Pb7, Copper Alloy CuSn7Zn4Pb7, Stainless Steel

Automation & Robotics

Parts:

Robot joints, Sensor housings, Mechanical arms

Recommended Materials:

Aluminum Alloys, Titanium Alloys

Aerospace & Aviation

Parts:

Structural components, Engine components, Aircraft wings

Recommended Materials:

Titanium Alloy Ti6Al4V, Aluminum-Lithium Alloys

Industrial Machinery Parts

Parts:

Gears, Bearings, Drive shafts

Recommended Materials:

Alloy Steel, Tool Steel

Lighting

Parts:

Lampshades, Brackets, Reflectors

Recommended Materials:

Aluminum Alloys, Polycarbonate

Recommendations for common materials

| Material Name | Features | Examples | Learn More | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Aluminum | Lightweight, corrosion-resistant, good thermal conductivity | 6061-T6, 7075-T6 | Browse CNC aluminum parts materials | ||||||||||||

| Stainless Steel | Corrosion-resistant, high strength | 304, 316 | Browse CNC Stainless Steel parts materials | ||||||||||||

| Carbon Steel | High strength, low cost | A36, 1018 | Browse CNC Carbon Steel parts materials | ||||||||||||

| Alloy Steel | Enhanced performance with added elements | 4140, 4340 | Browse CNC Alloy Steel parts materials | ||||||||||||

| Tool Steel | High hardness, wear-resistant | D2, A2 | Browse CNC Tool Steel parts materials | ||||||||||||

| Brass | Good electrical and thermal conductivity, corrosion-resistant | C36000, C26000 | Browse CNC Brass parts materials | ||||||||||||

| Copper | Excellent electrical and thermal conductivity | C11000 , C93200 | Browse CNC Copper parts materials | ||||||||||||

| Titanium | High strength, low density, corrosion-resistant | Ti-6Al-4V | Browse CNC Titanium parts materials | ||||||||||||

| Plastics | Lightweight, easy to process, chemical-resistant | ABS, PEEK, Nylon 6 | Browse CNC Plastics parts materials | ||||||||||||

Xielifeng CNC Machining Parts Case Study

Material Quality Control

We understand that the quality of raw materials is crucial to ensuring the superior performance of the final product. To guarantee that every batch of raw materials meets strict quality standards, we have established a comprehensive testing system equipped with advanced testing equipment and operated by an experienced professional team.

Advanced Testing Equipment

Xielifeng is equipped with a variety of advanced testing equipment to assess and ensure the quality of raw materials comprehensively.

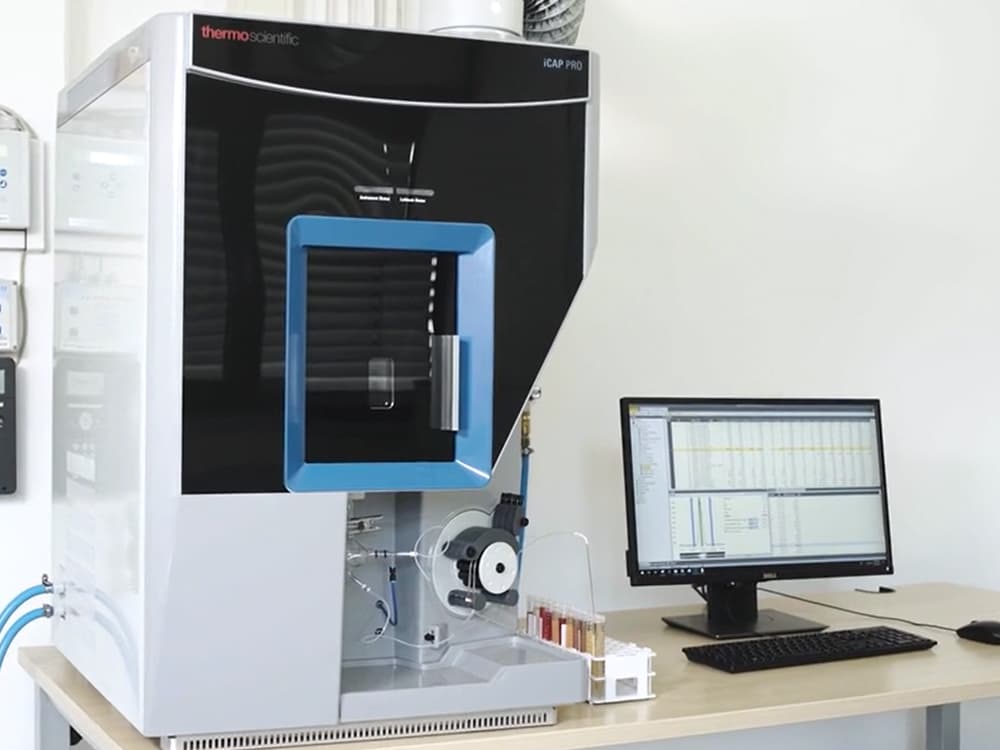

Spectrometer

Used to analyze the chemical composition of metals, ensuring element proportions meet standards.

Hardness Tester

Used to measure the hardness of materials, ensuring stability and durability during subsequent processing.

CMM

Used to measure the geometric dimensions of materials and parts, ensuring design conformity.

Tensile Testing Machine

Used to test the tensile strength and elongation of materials, ensuring their reliability in use.

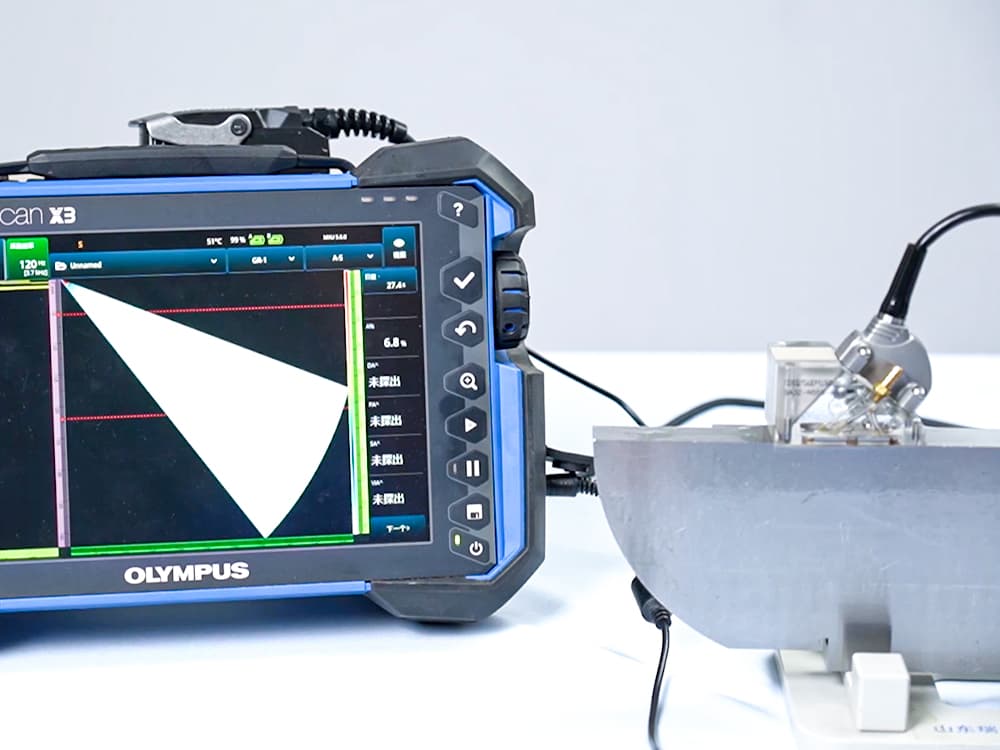

Ultrasonic Flaw Detector

Used to detect internal cracks and voids in materials, ensuring material integrity.

Xielifeng Professional Testing Team

Xielifeng’s testing team is composed of experienced professionals with extensive knowledge of materials science and rich practical experience. They are capable of accurately assessing the quality of materials.

Quality Manager (QM)

Name: Jason

Experience: 12 years

√ Reviewing and analyzing test results to ensure compliance with standards.

√ Developing and implementing quality control plans.

√ Organizing and coordinating audits to ensure compliance with quality standards.

Material Engineer (ME)

Name: Anthony

Experience: 10 years

√ Developing and implementing material testing protocols

√ Analyzing and resolving material performance issues and providing technical support.

√ Conducting material research and development projects.

Incoming Quality Control (IQC)

Name: Maria

Experience: 7 years

√ Performing initial inspections of incoming materials to ensure compliance with requirements.

√ Implementing and monitoring quality inspection procedures.

√ Preparing and maintaining quality inspection records.

Calibration Engineer (CE)

Name: Aisley

Experience: 8 years

√ Operating testing equipment, obtaining and recording data to ensure accuracy.

√ Conducting sample preparation and performance testing, providing test reports.

√ Maintaining and calibrating testing equipment.

.jpg)

Quality Engineer(QE)

Name: Callie

Experience: 5 years

√ Perform routine testing work, including sample preparation and data analysis.

√ Maintain laboratory environment and safety.

√ Assist engineers in material testing and recording data

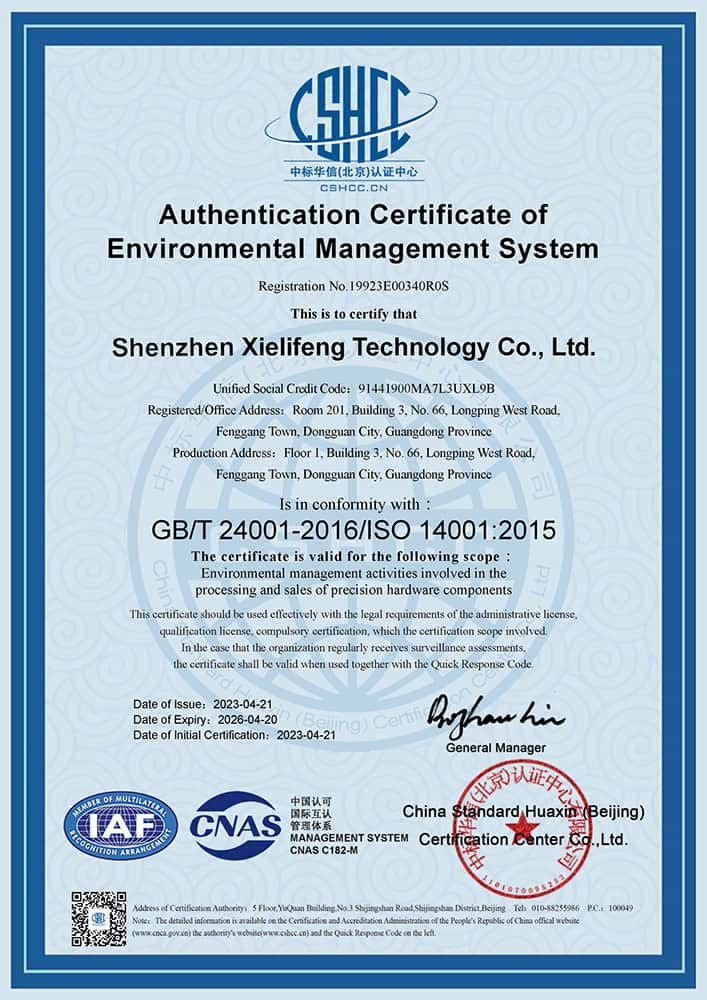

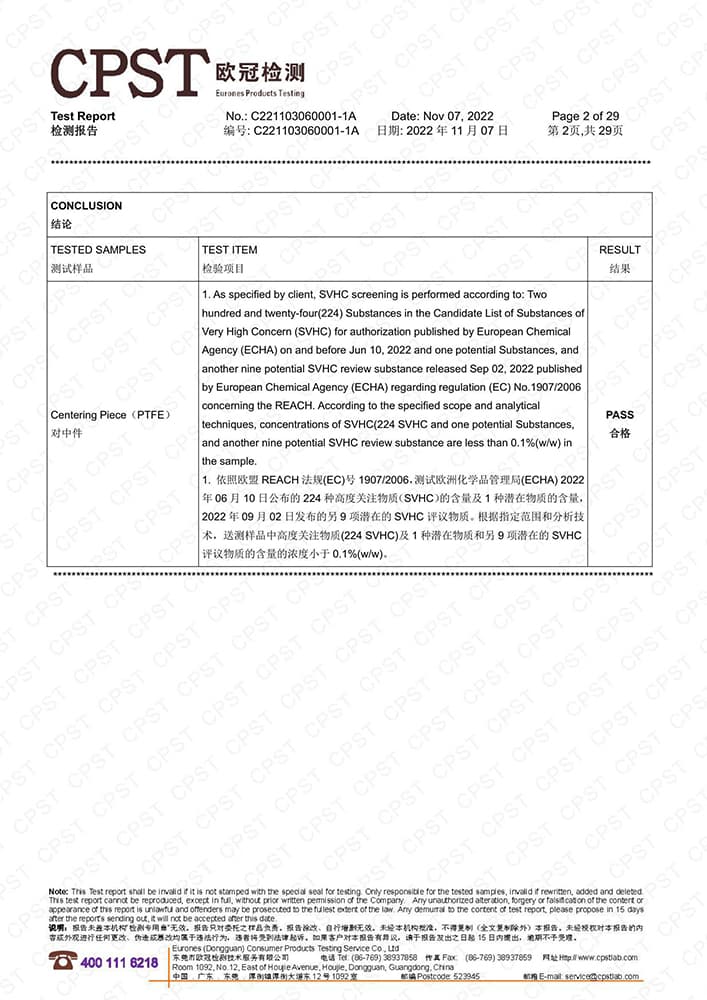

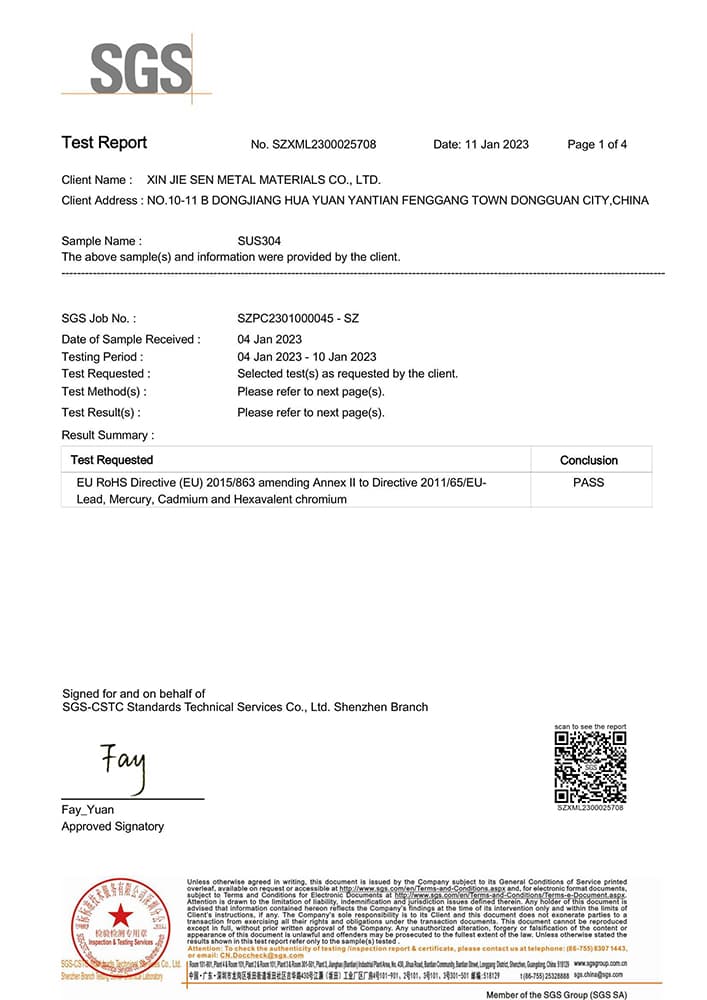

Material Certification & Inspection Report

ISO 9001

ISO 14001

Reach

RoHS

Quality Control Process for Raw Materials

Xielifeng has established a stringent raw material inspection process to ensure that every batch of raw materials undergoes comprehensive testing before production

01 Material Supplier Management

We have established a strict supplier management system, regularly auditing and evaluating suppliers’ performance to ensure they consistently provide high-quality raw materials.

02 Material Procurement

We only choose to work with reputable and reliable suppliers to ensure the stability and reliability of raw material sources.

03 Incoming Material Inspection

Upon arrival, the materials undergo initial inspection by material engineers and incoming inspectors to confirm their appearance and basic specifications.

04 Material Testing

Samples are taken from each batch of materials and subjected to comprehensive testing using equipment such as spectrometers, hardness testers, ultrasonic flaw detectors, X-ray fluorescence spectrometers, and CMMs.

05 Data Recording & Analysis

The Incoming Quality Control inspector meticulously records the inspection data, analyzes it, and confirms whether the materials meet the standards.

06 Results Review & Archiving

Once the test results are reviewed and approved, the records are archived. Approved materials are put into production, while non-conforming materials are returned to the supplier for further action.

How Xielifeng Works

From quotation to delivery, we provide efficient, high-quality services, making manufacturing more convenient.

01

Upload drawing

02

DFM Evaluation & Quote

03

Order Confirmtion & Production

04

Quality Inspection & Delivery