Die casting blank → die casting mold design → pouring system and gate design → cavity surface treatment (degreasing, rust removal, sandblasting) → design and manufacture of the closing guide mechanism → design and manufacture of the pressure injection system → design and processing of the top bar mechanism → design and manufacture of the side and bottom plates (including the paneling process) → cooling system design.

Part I. Casting process flow

1. Blank preparation.

(1) After the casting alloy is melted, it enters the cavity through the pouring system. In the process of metal liquid injection into the cavity, due to the liquidity and filling effect of the metal liquid, the metal liquid in the cavity to form a continuous flow structure, thus forming a certain shape of cavities and craters; at the same time, due to the filling effect of the metal liquid cavities gradually expand and fill the entire cavity.

(2) The air bubbles generated during the filling process will be eliminated with the discharge of the metal liquid; in addition, as the temperature drops, the bubbles will also shrink or disappear; finally, after a period of solidification, defects such as shrinkage or shrinkage will be produced.

(3) When the alloy liquid filling to a certain position will produce shrinkage stress and deformation of the casting phenomenon, this deformation is the result of thermal stress rather than cold stress caused.

(4) when the metal liquid filling to a certain depth will produce bonding force and make the surface of the castings produce sticky sand defects (i.e. sticky sand layer), when the alloy liquid impurity content is too high will make the thickness of the sticky sand layer more than the limit value of the material and cause the phenomenon of sticky sand layer off.

(5) When pressure casting at high temperatures due to thermal expansion and volume increase effect caused by dimensional changes and the appearance of porosity and other shortcomings.

(6) When the liquid alloy flows into the model through the gate, the gas volatilization will cause the vacuum level to increase due to the lowering of the gas pressure, resulting in poor venting and air holes.

Part II. Mould structure design

According to the structural form of die casting select the appropriate compression molding method and the corresponding mold structure and parts size specification range.

(1) For thin-walled products using integral structure of the mold.

(2) For thick-walled products, a split structure mold can be used.

(3) For complex structures with reinforced ribs, composite molds can be used.

(4) For large precision complex parts forming can take special purpose plastic pressing equipment.

(5) for some special materials can be used for special resin as raw materials to produce its special composite materials made of a variety of special-purpose parts.

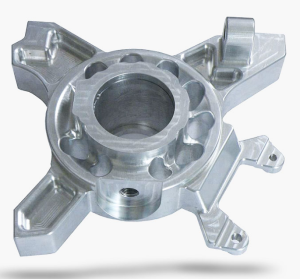

Need to die cast some parts, contact us now to get a quote.