Machining refers to the process of shaping or altering a workpiece using various cutting tools and machinery. It involves removing material from the workpiece to achieve the desired shape, size, or finish. Machining operations can include cutting, drilling, milling, turning, grinding, and more.

Machining is commonly used in manufacturing and fabrication industries to create precise and complex parts from various materials such as metal, plastic, wood, or composites. CNC (Computer Numerical Control) machines are often employed, which are automated systems that can execute machining operations with high precision and repeatability based on programmed instructions.

Overall, machining plays a crucial role in the production of a wide range of products, from simple components to intricate parts used in industries such as automotive, aerospace, electronics, and many others.

Conventional Machining Processes

Machining operations encompass a variety of processes used to shape, cut, or finish a workpiece. Here are some common machining operations:

Turning: In turning, a workpiece rotates while a cutting tool removes material to create a cylindrical shape. This operation is typically used to produce round parts like shafts, cylinders, or cones.

Milling: Milling involves using rotary cutters to remove material from a workpiece. It can create various shapes, slots, and features on the workpiece. Milling machines can perform a range of operations, including face milling, end milling, and peripheral milling.

Drilling: Drilling creates holes in a workpiece using a rotating drill bit. The drill bit is pressed into the workpiece, producing cylindrical holes. Drilling machines can be manual or automated, depending on the complexity and precision required.

Grinding: Grinding is a machining process that uses abrasive wheels to remove material and achieve a smooth, precise surface finish. It is often used for achieving tight tolerances and improving the surface quality of a workpiece.

Boring: Boring enlarges or refines existing holes in a workpiece using a single-point cutting tool. This operation is commonly used to achieve greater precision in hole diameter or to create tapered holes.

Broaching: Broaching is a process that uses a specialized tool called a broach to remove material in a controlled manner. It is often used for producing keyways, splines, or other internal or external profiles in a workpiece.

Sawing: Sawing involves cutting through a workpiece using a sharp-toothed blade. It is commonly used for cutting long bars, tubes, or other stock materials into desired lengths.

These are just a few examples of machining operations, and there are many more specialized operations and techniques used in different industries and applications. Each operation serves a specific purpose in shaping and finishing a workpiece to meet the desired specifications.

Non-conventional machining processes

Non-conventional machining processes, also known as unconventional or non-traditional machining processes, are a group of manufacturing techniques that do not rely on direct contact between a cutting tool and the workpiece. These processes are used when traditional machining methods are not feasible or effective for a particular material or desired outcome. Here are some examples of non-conventional machining processes:

Electrical Discharge Machining (EDM): EDM uses electrical discharges or sparks to remove material from a workpiece. It involves creating a controlled spark between an electrode and the workpiece, eroding the material. EDM is commonly used for intricate or hard materials like hardened steel or exotic alloys.

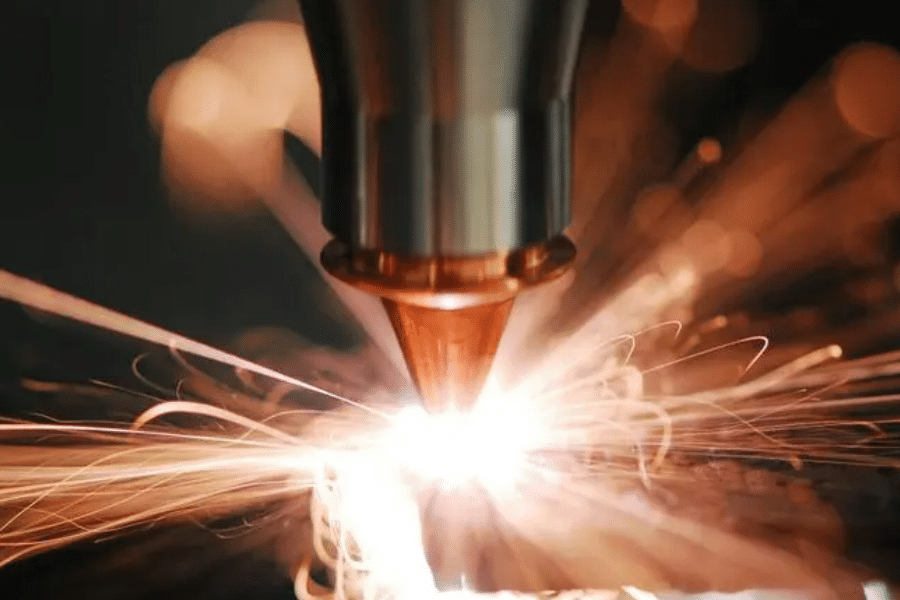

Laser Cutting: Laser cutting employs a high-powered laser beam to melt or vaporize the material, resulting in precise cutting. It is widely used for cutting various materials, including metal, plastic, wood, and fabric.

Waterjet Cutting: Waterjet cutting uses a high-pressure jet of water, often mixed with abrasive particles, to cut through materials. It is suitable for cutting a wide range of materials, including metal, stone, glass, and composites.

Electrochemical Machining (ECM): ECM uses the principles of electrochemistry to remove material from the workpiece. It involves immersing the workpiece and an electrode in an electrolyte solution while applying a current to dissolve the material.

Ultrasonic Machining (USM): USM utilizes ultrasonic vibrations and abrasive slurry to remove material from the workpiece. The high-frequency vibrations generated by a tool cause the abrasive particles to impact and erode the material.

Chemical Machining (CM): CM involves selectively removing material from a workpiece using chemical etchants. A mask or resist is applied to protect certain areas, while the etchant selectively dissolves the exposed regions.

Electron Beam Machining (EBM): EBM uses a focused beam of high-velocity electrons to remove material from the workpiece. It is commonly used in industries like aerospace and automotive for precision drilling, welding, and cutting.

These non-conventional machining processes offer unique advantages for specific applications, such as the ability to work with difficult-to-machine materials, achieve intricate shapes, or minimize heat-affected zones. However, they also have limitations and considerations that need to be taken into account when selecting the appropriate method for a particular machining task.