The CNC machining center adopts a CNC machine tool with its own tool magazine and automatic tool change, which can realize continuous processing of multiple processes by one clamping. In recent years, CNC multi-axis machining centers have developed rapidly due to reducing errors and improving part accuracy and machining efficiency.

Improving the production efficiency of the CNC machining process is not only an update of the process concept, but also an improvement in the management concept. Use advanced tools and machine tools to achieve high-speed and efficient cutting, and at the same time use relevant technologies and management methods to optimize the entire processing process, improve processing efficiency through various ways, and achieve high-speed cutting.

CNC five-axis machining adopts XYZABC five-coordinate linear interpolation motion, and the five-axis machining machine is called a five-axis machining center. The five-axis machining center can not change the different surfaces of the workpiece at the position of clamping the workpiece, which can greatly improve the processing efficiency.

High efficiency: One equipment is equipped with dual lasers (nanosecond pulse laser), which can realize rough and fine machining of tools, reduce the precision errors caused by rough replacement of equipment and the number of times of tool clamping, and greatly improve tool processing efficiency, machining accuracy and machining. quality.

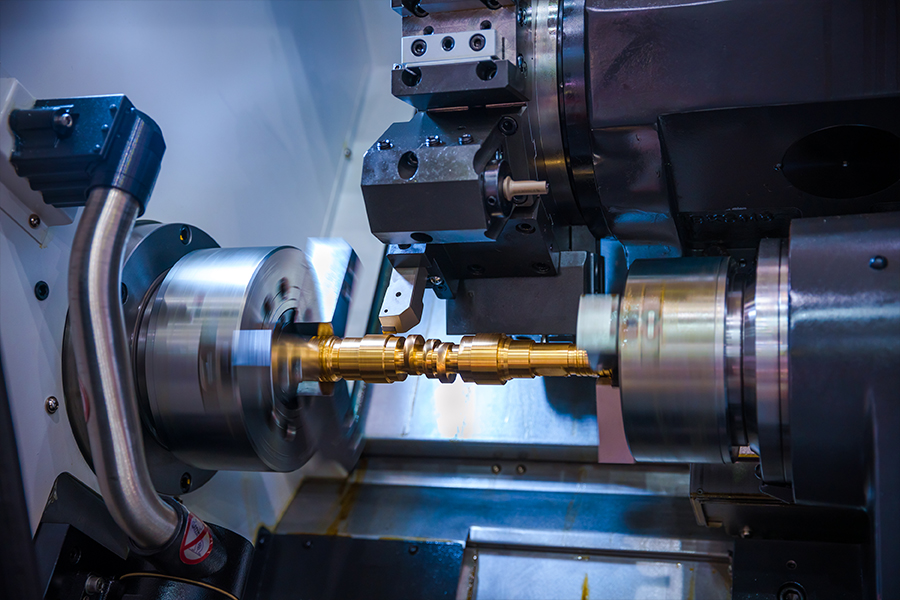

Computer Numerical Control (CNC) machining is an important manufacturing technology used to make metal or other materials (such as plastics) into various specifications according to different requirements. In addition to adding, cutting or removing material, CNC machining can also help get the desired shape with minimal effort. Turning tools and shafts use different processing methods, such as turning, milling, etc., with the best results. Such processing technologies are designed to increase energy efficiency, limit the production of by-products, and overcome processing errors associated with traditional processes. Due to its increasing popularity, it is easy to find several workshops today that specialize in various CNC machining services. This article focuses on several common CNC machining services and their applications.

CNC is the English abbreviation of Computer Numerical Control Program Controlled Machine Tool. It can process the control coding instruction program and decoding, so that the machine tool and the tool can work on the workpiece. CNC machine tools have high precision and stability that ordinary machine tools do not have, and CNC machine tools can process high-precision parts that ordinary machine tools cannot.

Errors caused by time difference and intermediate processes can improve the machining accuracy of parts, shorten the product manufacturing cycle, improve production efficiency and the manufacturer’s market responsiveness. Compared with traditional decentralized production methods, it has obvious advantages. But it cannot be said that one CNC machining center can complete all the work. There are many models of CNC machining centers. The compound machine refers to the completion of, or as far as possible, the processing of multiple elements from blank to finished product on one machine tool. According to its structural characteristics, it can be divided into two types: process composite and process composite. Machining compound machine tools such as boring, milling and drilling compound machine tools – machining centers of different types of CNC machining centers are applicable in different aspects.

The machines are connected in parallel, and the general processing technology performance is relatively stable. The processing service center can be combined with the turning center or the horizontal machining center to improve the processing application range and processing capacity of CNC machining.

More keywords: cnc machining aluminum, cnc machining brass, cnc machining stainless stteel, cnc brass parts, cnc aluminum parts, cnc steel parts