Get Precision and Reliability in CNC Appliance Components

±0.005mm Precision for Critical Components

99.8% Interchangeability in Mass Production

Custom Solutions Delivered in 1-2 Weeks

All uploads are secure and confidential.* Learn More

IOS 9001

IOS 14001

About Our Capabilities

Extreme Precision and Geometry Machining

High Consistency in Precision Assembly Parts

Efficient Production and Strict Quality Control

Extreme Precision and Complex Geometry Machining

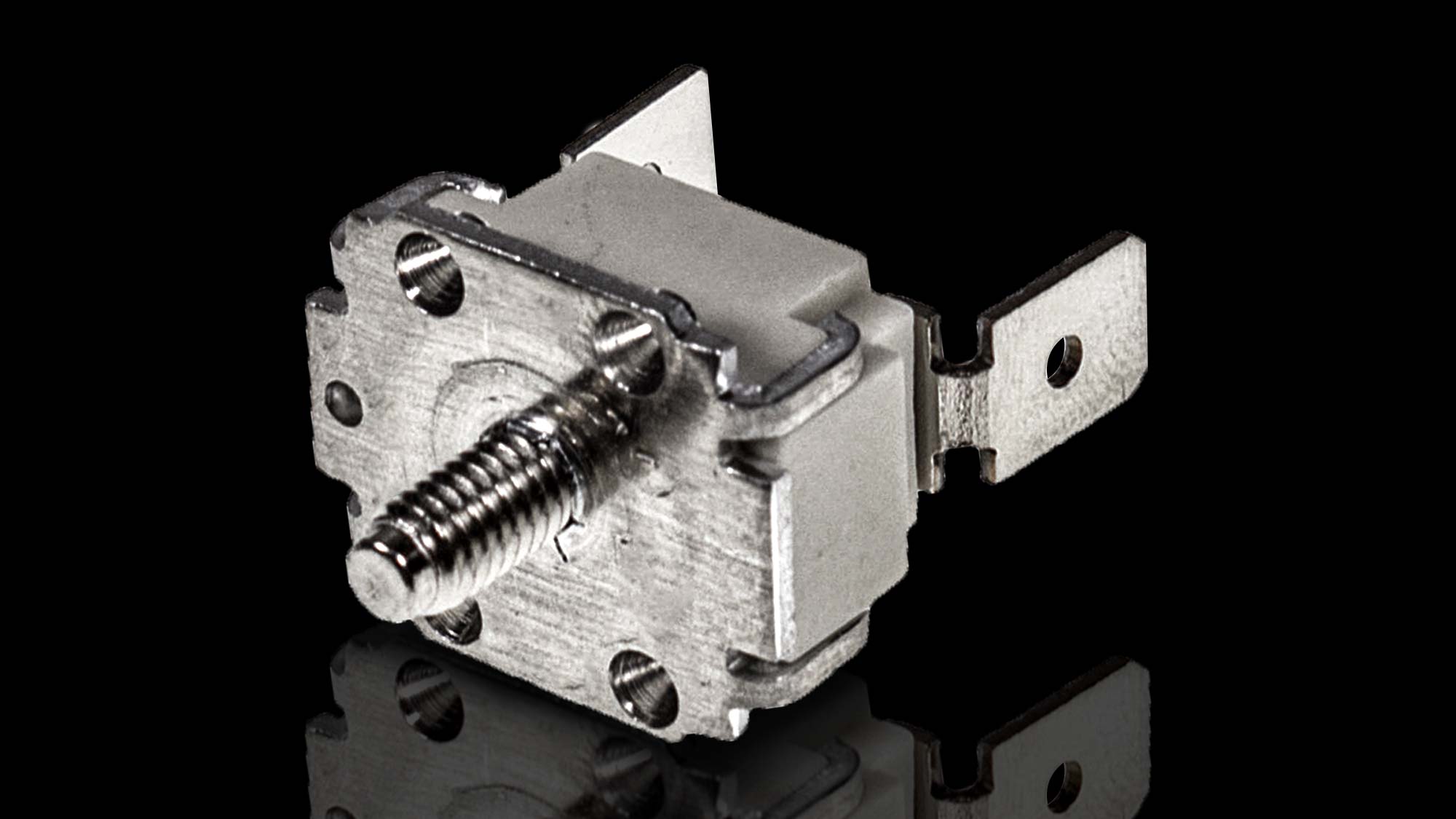

Specializing in high-value appliance components (e.g., high-end motor parts, precision sensor housings).

Tolerance precision controlled within ±0.003mm.

Annually producing 200,000+ high-precision complex parts, ensuring superior performance.

High Consistency in Precision Assembly Parts

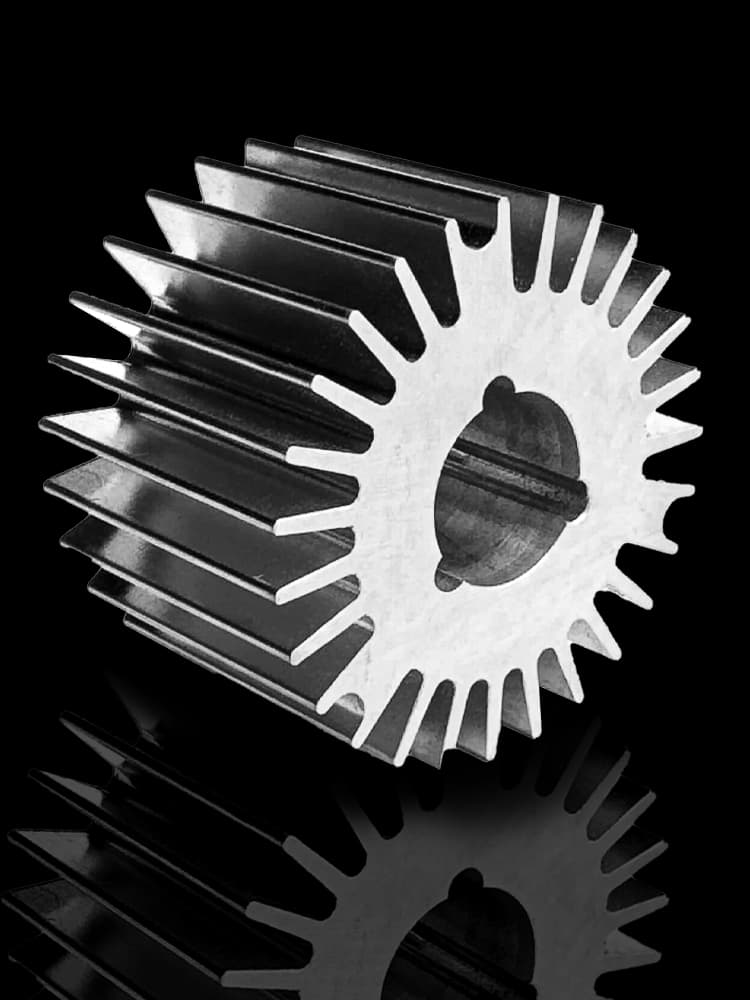

Machining tight-tolerance bushings, couplings, and micro-gears.

Achieving 99.8% part interchangeability in mass production.

Strict inspection minimizes adjustment time and rework in assembly.

Efficient Production and Strict Quality Control

From design validation to mass production in as fast as 5 days.

Full-process quality monitoring with a 99.9% pass rate.

Meeting or exceeding strict high-end appliance standards.

Application of parts for Household Appliances

| Materials | Feature | Application Parts | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

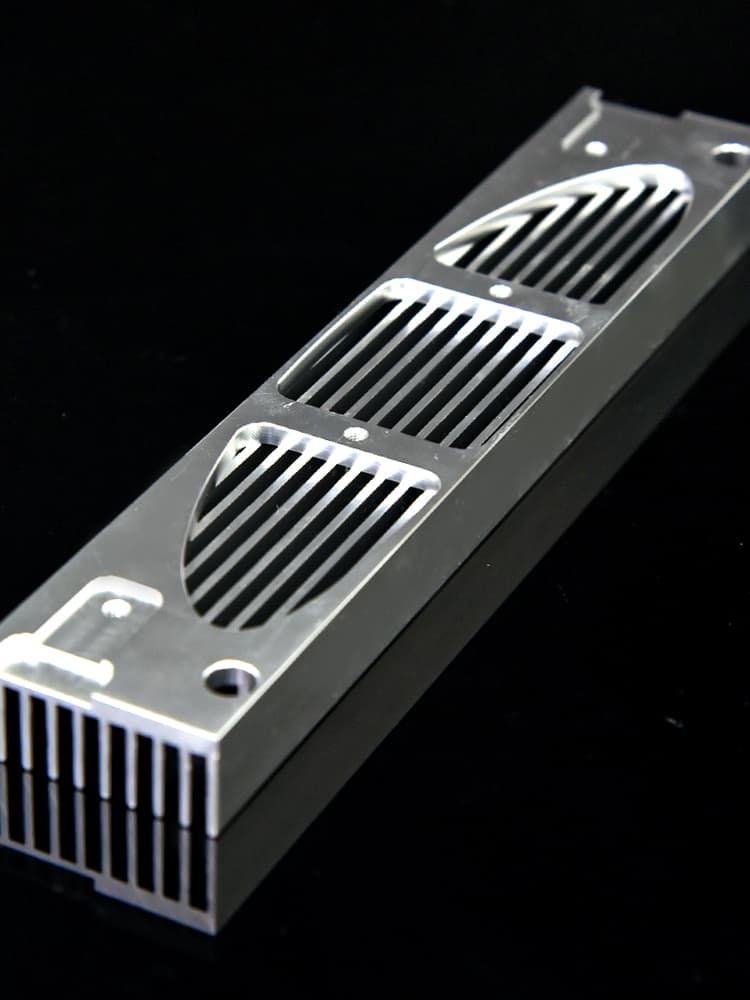

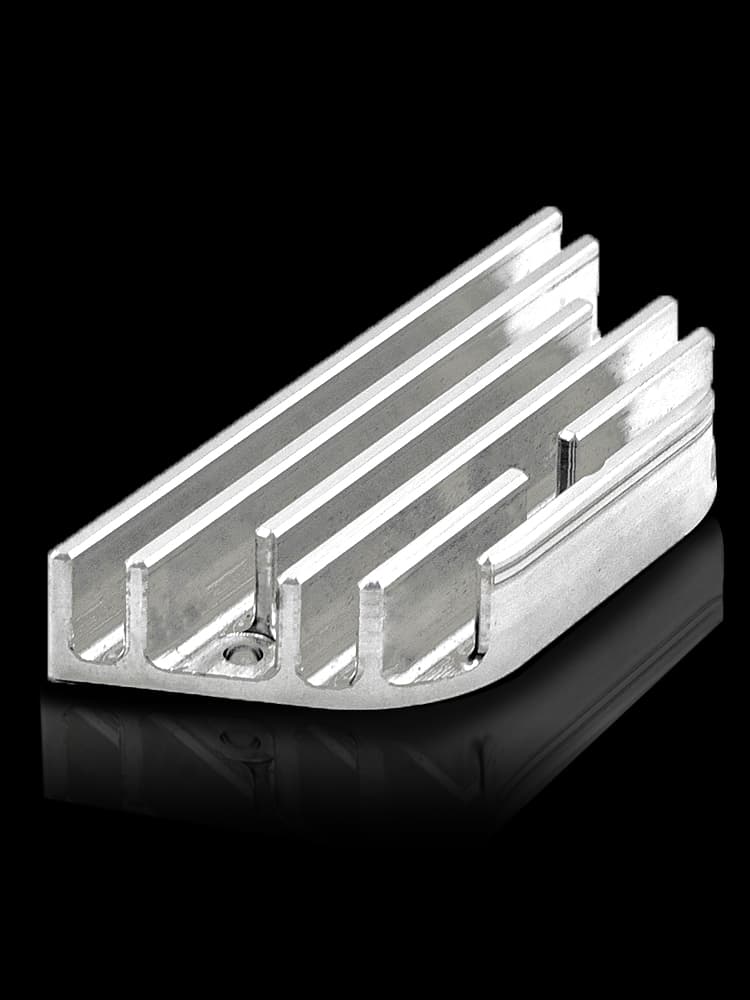

| Aluminum | Lightweight, high strength, corrosion resistance, good thermal conductivity | Heat sinks, exterior parts, fan blades | |||||||||||||

| Stainless Steel | Excellent corrosion resistance, high strength, wear resistance, easy to clean | Compressed air cylinder cases, interior trim, filter housings | |||||||||||||

| Steel | High strength, wear resistance, low cost, weldable | Structural supports, exterior parts, bearing housings | |||||||||||||

| Brass | Good electrical conductivity, corrosion resistance, easy to machine | Connectors, terminals, joints (electrical connections) | |||||||||||||

| ABS | Good mechanical properties, impact resistance, heat resistance, easy to mold | Exterior parts, control panels, buttons | |||||||||||||

| PP | Lightweight, chemical resistance, good insulation, heat resistance | Interior trim, water tanks, filter components | |||||||||||||

| PC | High transparency, high strength, corrosion resistance, impact resistance | Transparent covers, control panels, display screens | |||||||||||||

| PA | High strength, wear resistance, heat resistance, chemical resistance | Gears, bearing housings, fasteners | |||||||||||||

Surface Treatment of Household Appliances Parts

| Surface Treatment | Feature | Application Parts | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Electroplating | Improves corrosion resistance and wear resistance of components | Connectors, terminals, fasteners, trim parts, control panels | ||||||||||||

| Anodizing | Increases surface hardness, wear resistance, corrosion resistance, color options, enhances aesthetics | Aluminum panels, control panels, trim parts, heat sinks, exterior parts | ||||||||||||

| Powder Coating | Provides a uniform protective layer, corrosion resistance, wear resistance, eco-friendly | Exterior parts, panels, frames, trim parts | ||||||||||||

| Heat Treatment | Improves mechanical properties (hardness, strength), enhances wear resistance | Gears, axles, frames, fasteners | ||||||||||||

| Polishing | Provides a smooth surface, enhances gloss, aesthetics, easy to clean | Trim parts, control panels, display screens, interiors | ||||||||||||

| Zinc plating | Corrosion resistance, increased wear resistance, cost-effective | Steel exterior parts, supports, frames, fasteners, clamps | ||||||||||||

| Nickel Plating | Increases hardness, corrosion resistance, provides a uniform finish | Connectors, terminals, fasteners, electronic parts, trim parts, control panels | ||||||||||||

| Brushing | Enhances surface aesthetics, adds texture, prevents fingerprints | Stainless steel exterior parts, trim parts, control panels | ||||||||||||

| Sand blasting | Provides a uniform matte finish, enhances aesthetics, prevents reflections | Aluminum exterior parts, trim parts, control panels | ||||||||||||

| PVD Coating | Increases hardness, wear resistance, corrosion resistance, aesthetics | High-end trim parts, control panels, fasteners | ||||||||||||

CNC Household Appliances Parts Case Study

Our Partners

Household Appliances Industry Engineer Andrew from Xielifeng Has Something to Say

Senior Engineer Andrew, 10 years of experience in machining high-precision, high-value internal components for advanced household appliances. Specialized in miniature mechanical parts and electrical connectors for smart appliances, ensuring consistent quality and tight tolerances.

How do you manage the tight tolerances required for smart appliance components?

We use high-precision CNC machines to achieve tolerances as tight as ±0.005 mm. To maintain consistency, we conduct real-time dimensional monitoring during production and use coordinate measuring machines (CMMs) for post-production verification. This ensures that every component meets the exact specifications needed for smooth operation in compact designs.

How do you ensure electrical connectors perform reliably over time?

We use gold-plating or tin-plating on electrical connectors to enhance conductivity and resist oxidation. Additionally, we conduct repeated insertion and withdrawal testing to ensure durability. Our quality control team also performs environmental testing to simulate high humidity or temperature changes to guarantee long-term reliability.

What are the specific challenges of machining parts for smart and IoT-enabled appliances?

One challenge is handling the delicate nature of sensors and connectors used in IoT devices. These components require micro-machining techniques and anti-static processing to prevent damage. Additionally, IoT appliances demand compact designs, so we must maintain high precision without adding unnecessary bulk.

How do you meet evolving customer expectations for smarter, more efficient appliances?

We collaborate with clients to develop customized solutions that align with emerging trends. For instance, we help integrate energy-efficient components and optimize parts for silent operation. Through rapid prototyping and iterative feedback, we ensure that our components meet the functional and aesthetic demands of next-generation appliances.

How do you ensure consistency across large production batches?

We implement statistical process control (SPC) to monitor production quality in real-time. Our modular production lines allow for quick adjustments if any deviations are detected. Additionally, we conduct first-article inspections at the start of each batch to verify that the setup meets client specifications, minimizing the chance of defects.

How do you meet urgent production deadlines without compromising quality?

We maintain in-house material stock and flexible production schedules to quickly respond to urgent orders. Our lean manufacturing system minimizes downtime, ensuring efficient workflows. We also provide real-time progress updates to clients, helping them stay on track with their project timelines.

How Xielifeng Works

From quotation to delivery, we provide efficient, high-quality services, making manufacturing more convenient.

01

Upload drawing

CAD files: 2D: DXF | DWG | PDF 3D: STP | STEP |IGS | IGES| X_T | SLDPRT

02

DFM Evaluation & Quote

- Drawing review

- Process analysis

- Material inspection

- Feasibility proposal

- Cost estimation

03

Order Confirmtion & Production

- Sample processing

- Sample quality inspection

- Customer confirmation

- Mass production plan

04

Quality Inspection & Delivery

- Raw material inspection

- First piece inspection

- Process inspection

- Final inspection

- Inspection report