24 Years of Expertise in Precision Electronics Machining

±0.005mm Precision for Your 3C Components

3-Day Prototyping, 1-Week Production

Cut Costs by 20% Without Sacrificing Quality

All uploads are secure and confidential.* Learn More

IOS 9001

IOS 14001

About Our Capabilities

High-Precision Micro-Parts Machining

Rapid Prototyping and Small Batch Production

Lean Production and Cost Control

High-Precision Micro-Parts Machining

Micro-parts machining tolerance of ±0.005mm.

Annually machining over 500,000 key components for smartphones and laptops.

Ensuring high performance and reliability in miniaturized devices.

Rapid Prototyping and Small Batch Production

Complete rapid prototyping within 3 days.

Start small-batch production within 1 week.

Provide quick response services for over 100 3C projects annually.

Lean Production and Cost Control

Reduce defect rate to below 1%.

Help customers reduce manufacturing costs by an average of 20%.

Optimize costs while maintaining high quality.

Application of Custom Electronics Parts

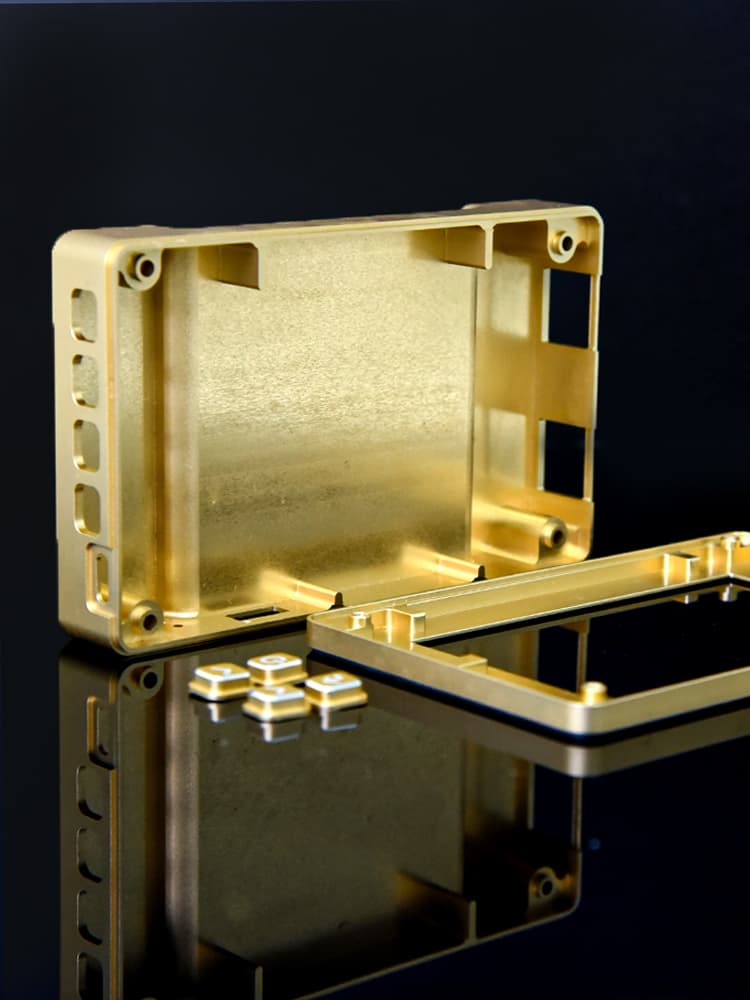

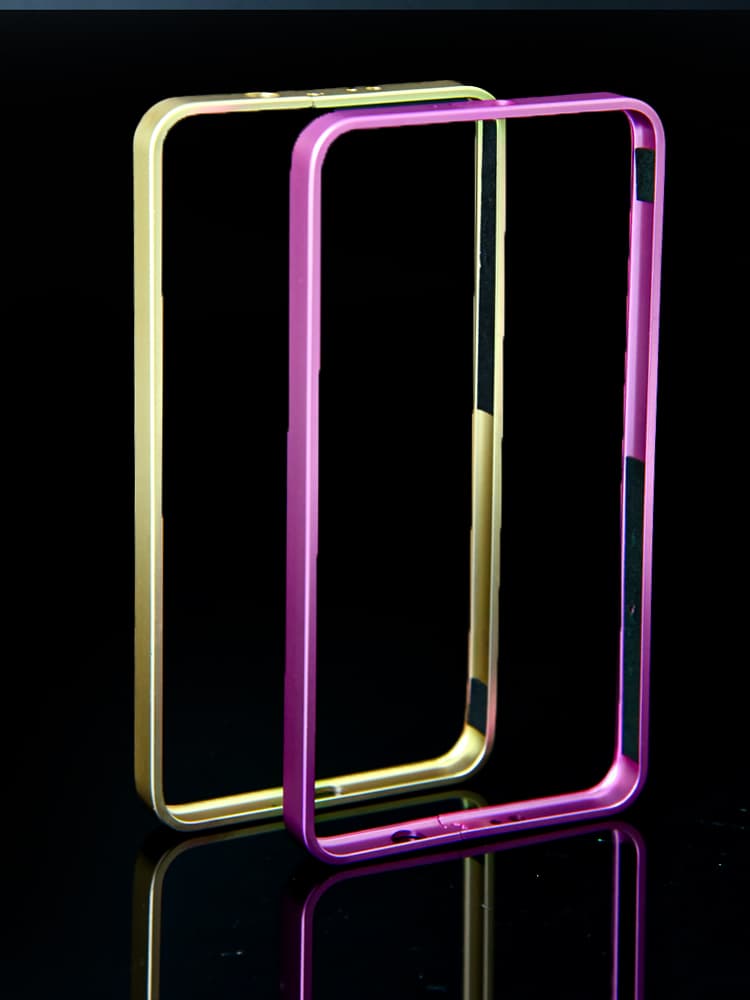

Consumer Electronics

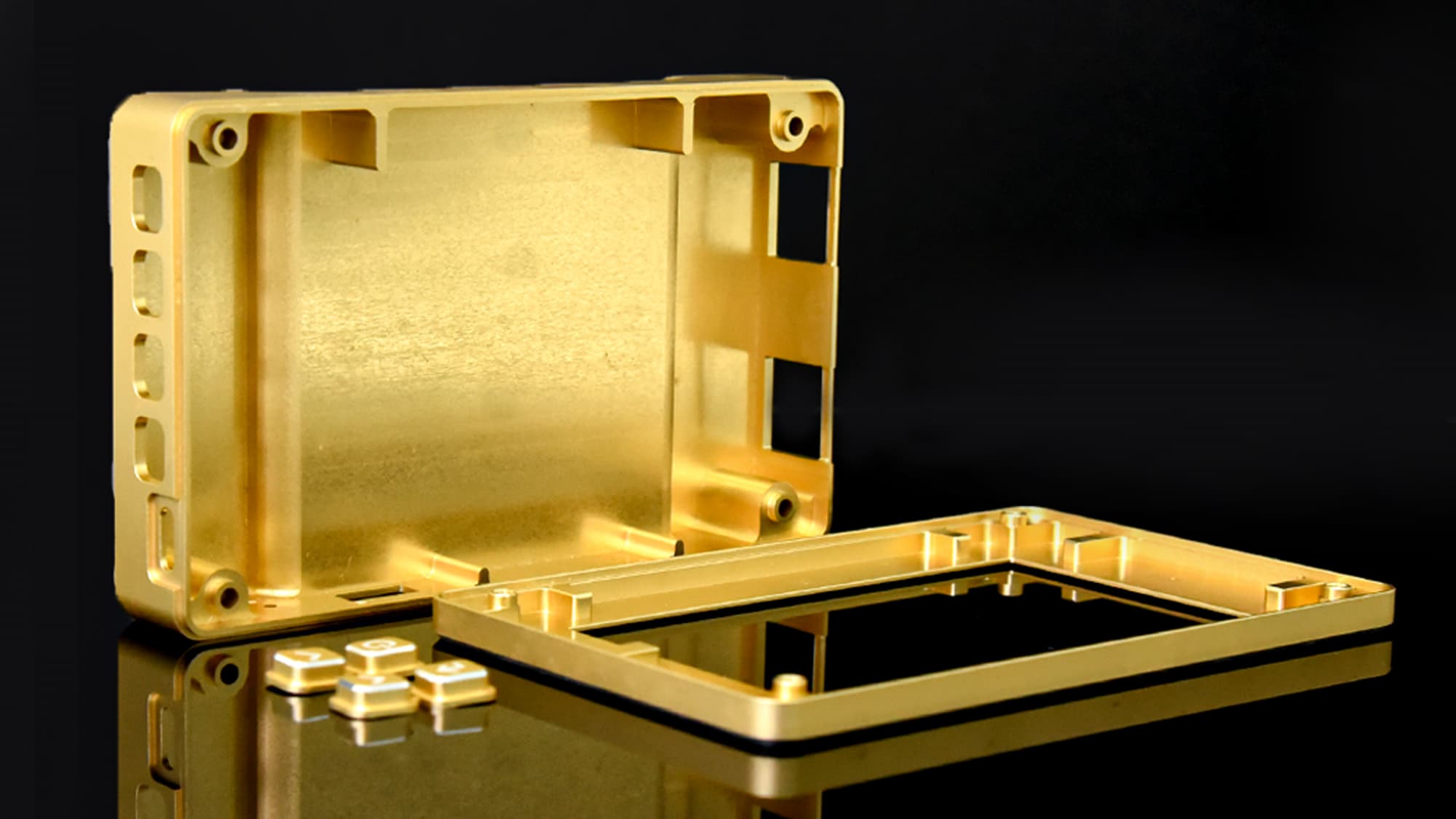

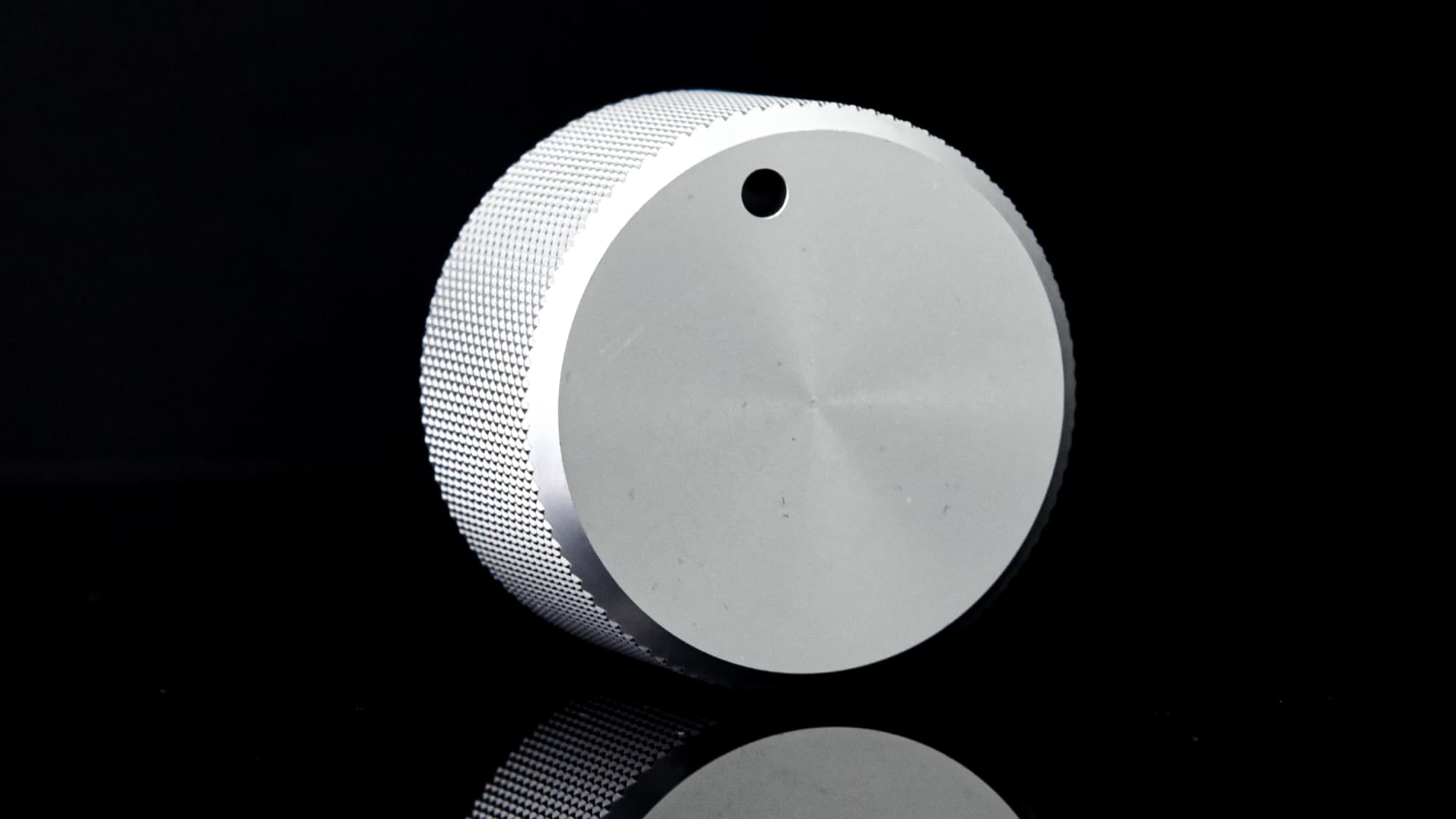

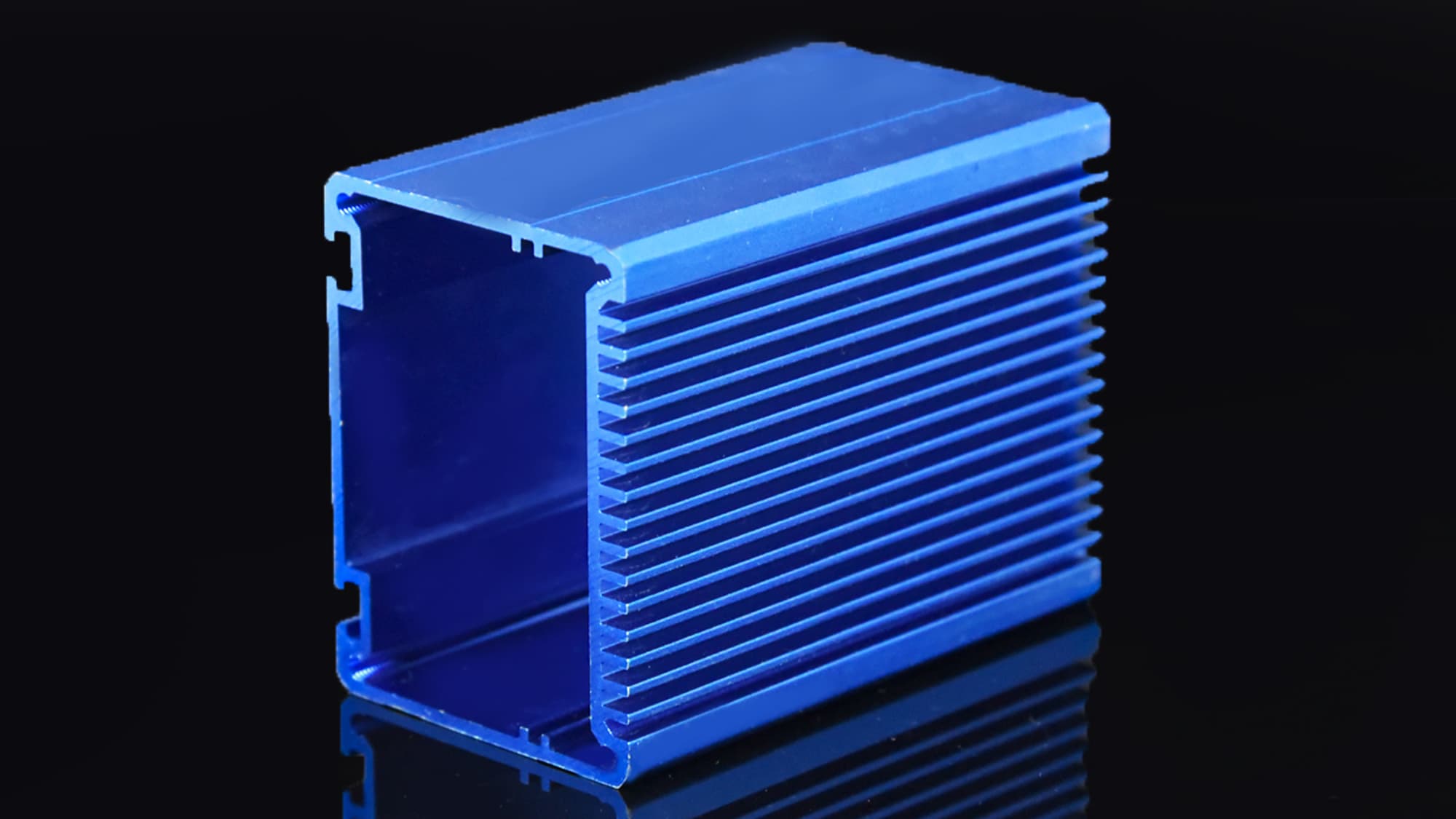

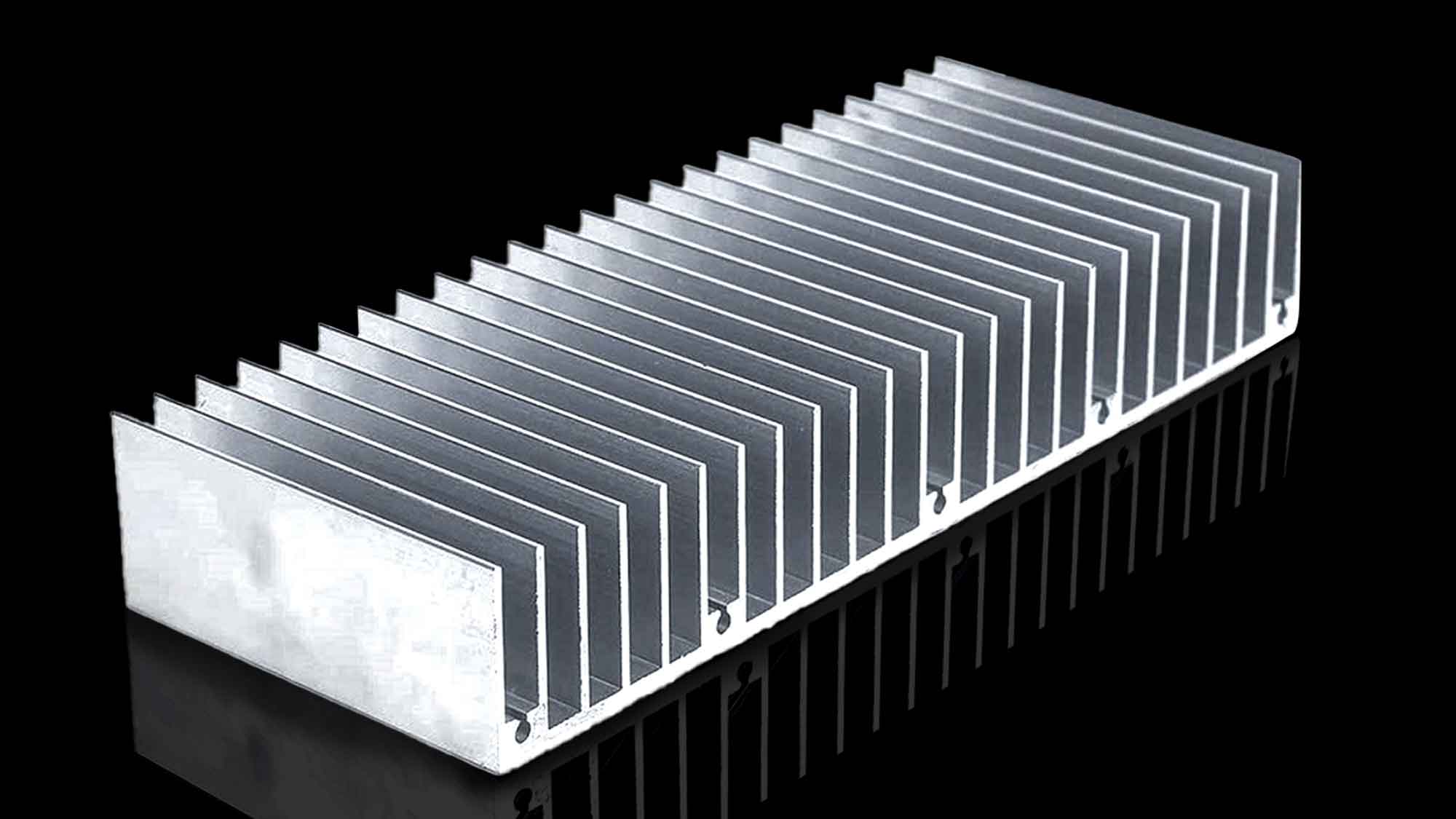

Enclosures (e.g., smartphones, tablets), Heat sinks, Buttons, Keys, Connectors, Plugs, Terminals

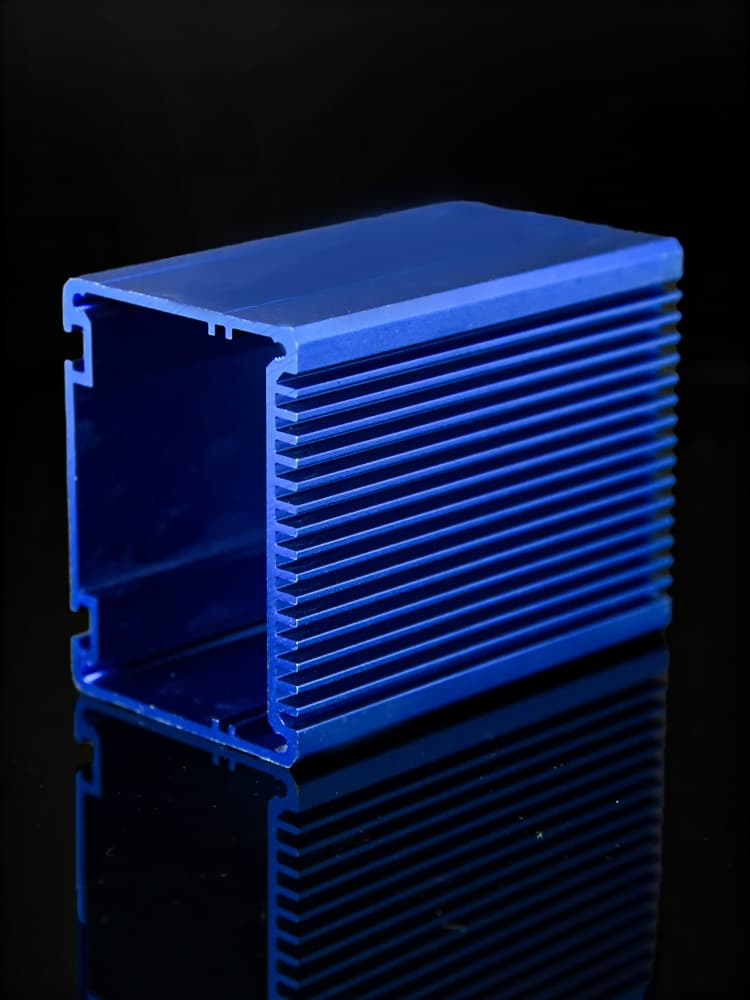

Telecommunications Electronics

Base station enclosures, Heat sinks, Frame structures, Connectors, Mounting brackets, Antenna components, Fasteners, Connectors

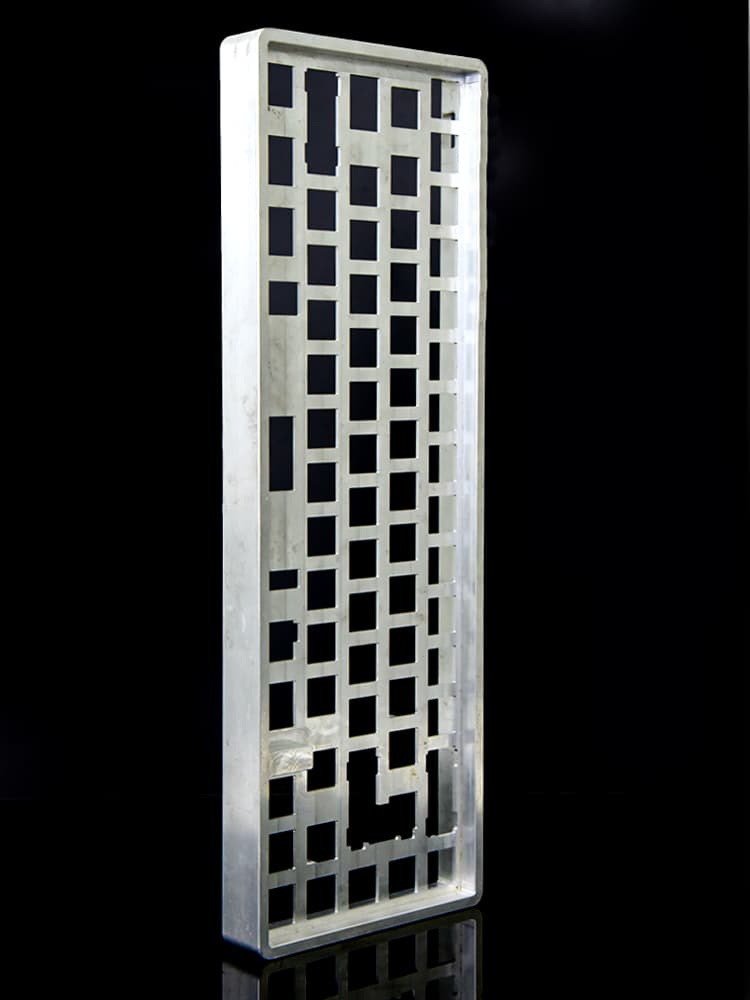

Computers

Enclosures (e.g., laptop cases, desktop cases), Heat sinks, Frame structures, Structural brackets, Interface connectors, Keyboard enclosures, Internal brackets, Decorative parts

Materials for CNC Electronics Parts

| Name | Characteristics | Applicable Parts | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Aluminum | Good thermal conductivity, lightweight, oxidation resistance | Heat sinks, enclosures, circuit board supports, electrolytic capacitor casings | |||||||||||||

| Stainless Steel | Good corrosion resistance, high strength, good machinability | Wires, screws, brackets, grounding wires, supports | |||||||||||||

| Steel | Good strength, good machinability, relatively low cost | Equipment casings, structural supports, device enclosures, electronic device structural components | |||||||||||||

| Brass | Good electrical and thermal conductivity, corrosion resistance | Connectors, terminals, screws, connector components, and screws in electronic devices | |||||||||||||

| Copper | Good electrical conductivity and thermal conductivity, high stability | Wire casings, circuit board casings, grounding wires, connectors | |||||||||||||

| PP (Polypropylene) | Lightweight, good chemical resistance, good impact resistance | Small appliance casings, power supplies, electronic connectors | |||||||||||||

| PE (Polyethylene) | Low cost, good corrosion resistance, lightweight | Insulation tubes, electrical cable insulation tubes, flexible packaging materials | |||||||||||||

| PC (Polycarbonate) | Good machinability, high strength, heat resistance, transparency | Device casings, display screens, insulators, heat sinks, power supplies | |||||||||||||

| PS (Polystyrene) | Good transparency and insulation, good moldability | Electronic device housings, telephones, decorative parts, buttons | |||||||||||||

| PA (Nylon) | Good mechanical properties, high strength, good wear resistance | Structural gears, transmission parts | |||||||||||||

CNC Electronics Parts Post-Processing Capabilities

| Surface Treatment | Characteristics | Electronic Components | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Electroplating | Enhances appearance, corrosion resistance, conductivity | Terminals, circuit boards, metal enclosures | ||||||||||||

| Anodizing | Improves durability and corrosion protection of aluminum | Heat sinks, electronic enclosures, plug housings | ||||||||||||

| Painting | Provides coatings with various colors and effects | Enclosures, panels, decorative parts | ||||||||||||

| Heat Treatment | Increases hardness and wear resistance of parts | Metal enclosures, metal supports, metal connectors | ||||||||||||

| Zinc plating | Enhances corrosion resistance of parts | Screws, nuts, metal enclosures, supports and fasteners | ||||||||||||

Custom Electronics Parts Case Study

Our Partners

Electronics Parts Engineer Grace from Xielifeng Has Something to Say

Senior Engineer Grace, 10 years of experience in machining high-precision components for consumer electronics, communication devices, and computer hardware. Expert in tight-tolerance machining and miniaturized parts manufacturing, ensuring reliability and performance in compact designs.

How do you ensure precision when machining small electronic components?

We use ultra-precision CNC machines capable of machining parts with tolerances as tight as ±0.005 mm. Regular tool maintenance and environmental control (e.g., temperature and humidity) further ensure consistent accuracy, especially for sensitive components such as connectors and housings.

What materials are best suited for electronic components?

Aluminum and stainless steel are commonly used for their lightweight and corrosion resistance properties, making them ideal for device housings. Brass is often chosen for connectors due to its excellent electrical conductivity. Plastics such as PEEK and ABS are preferred for insulation parts and lightweight structures.

How do you manage heat dissipation challenges in electronic component machining?

For components that require thermal management, such as heat sinks, we use high thermal conductivity materials like aluminum and apply anodizing treatments to improve performance. We also collaborate with clients to optimize the part’s geometry for efficient heat dissipation.

What challenges do you encounter when machining parts for consumer electronics?

The main challenge is achieving tight tolerances while maintaining high production efficiency. Miniaturized parts are more prone to deformation during machining. We address this by using specialized fixtures to stabilize parts and conducting multi-stage inspections to ensure precision at every step.

How do you ensure surface quality for electronic parts?

We perform polishing and anodizing to achieve smooth, corrosion-resistant surfaces for metal parts. For plastic components, we offer spray coating and UV curing treatments to enhance surface durability and appearance. Our quality control team conducts visual inspections and surface roughness testing to meet aesthetic and functional standards.

How do you meet the fast-changing demands of the electronics industry?

We stay agile by maintaining a flexible production system and offering rapid prototyping services. This allows us to quickly adapt to design changes and new product requirements. Our close communication with clients ensures on-time delivery and reduces production delays.

How Xielifeng Works

From quotation to delivery, we provide efficient, high-quality services, making manufacturing more convenient.

01

Upload drawing

CAD files: 2D: DXF | DWG | PDF 3D: STP | STEP |IGS | IGES| X_T | SLDPRT

02

DFM Evaluation & Quote

- Drawing review

- Process analysis

- Material inspection

- Feasibility proposal

- Cost estimation

03

Order Confirmtion & Production

- Sample processing

- Sample quality inspection

- Customer confirmation

- Mass production plan

04

Quality Inspection & Delivery

- Raw material inspection

- First piece inspection

- Process inspection

- Final inspection

- Inspection report