CNC Turning Services

Machining Accuracy up to ±0.005mm

Over 200 Material Choices

99% On-Time Delivery Rate

95% Customer Satisfaction

Your drawing&design is safe with us.* Learn More

IOS 9001

IOS 14001

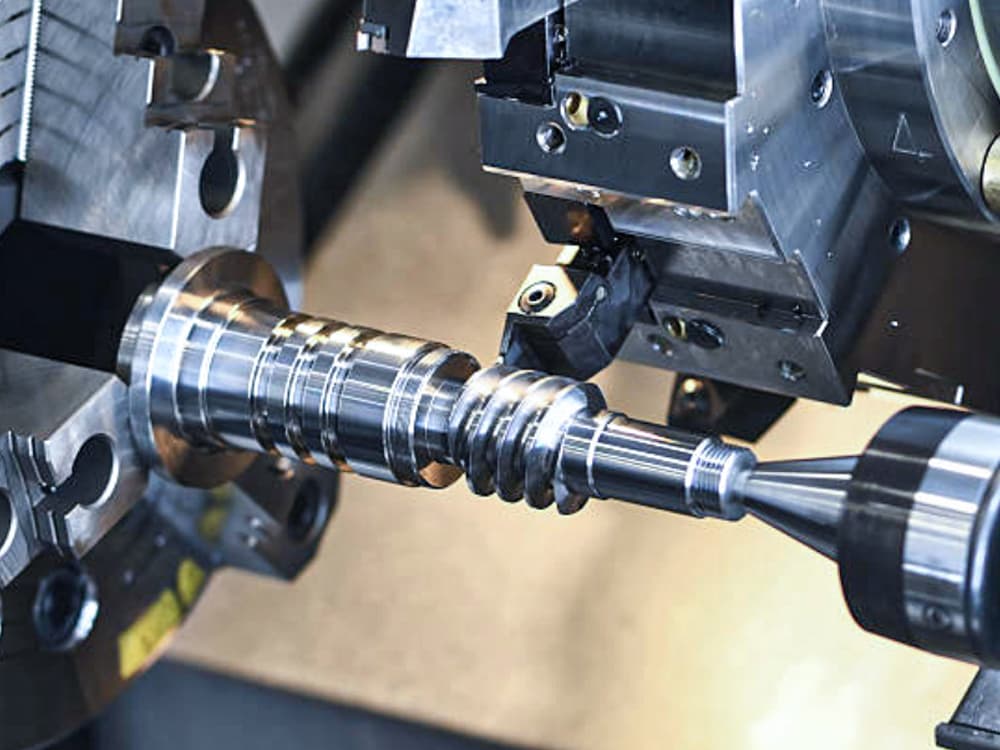

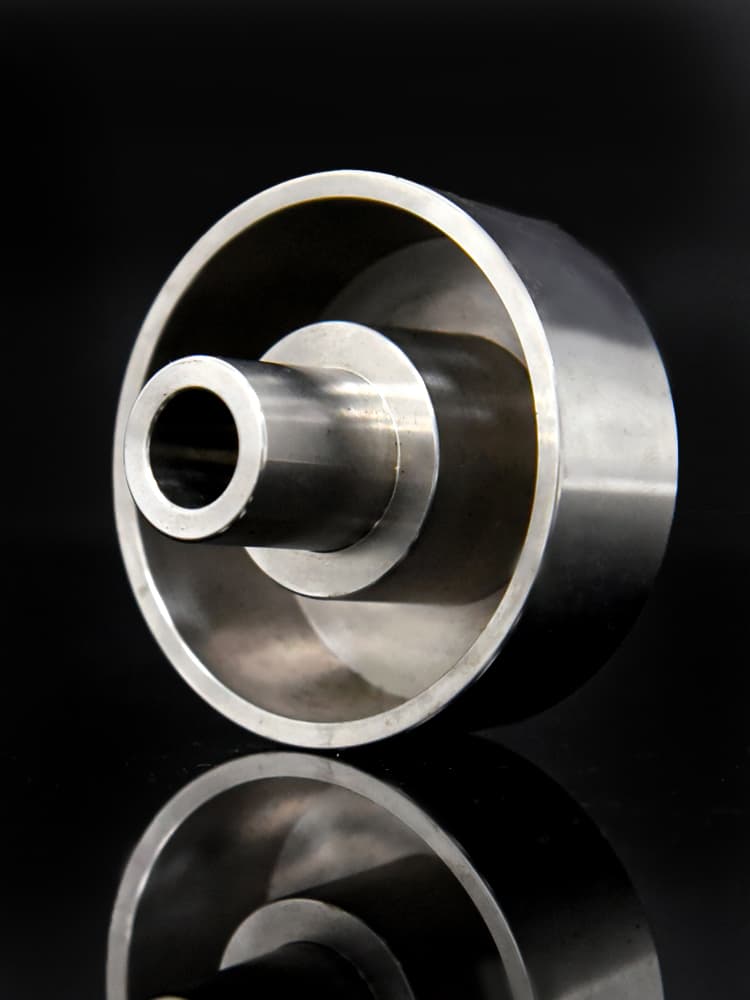

What is CNC Turning?

CNC turning is a process where a computer-controlled lathe rotates the workpiece while a cutting tool shapes it into cylindrical parts. The workpiece is fixed on a rotating spindle, and as it spins, the tool moves along its length based on the programmed design. This process can include threading, grooving, and drilling while maintaining high precision and smooth finishes.

What's the Features of CNC Turning?

· Efficient Production: Suitable for high-volume production with consistent results.

· Versatile Machining: Capable of performing multiple operations like threading, grooving, and drilling.

· Smooth Surface Finish: Provides excellent surface quality, reducing the need for additional finishing processes.

What's the CNC Turning Typical Applications

CNC turning is widely used for manufacturing cylindrical parts such as shafts, bushings, threaded components, and complex rotational geometries, covering industries like automotive, aerospace, electronics, plumbing, and industrial machinery.

CNC Turning Processing Classification

- By processing type

- External Turning: Machines outer surfaces, ideal for shafts.

- Internal Turning: Creates internal holes, like in bushings or sleeves.

- Facing Turning: Cuts end faces to adjust length and finish.

- Thread Turning: Produces threads for bolts, nuts, and similar parts.

- By Shape and Geometry

· Cylindrical Turning: Regular machining of cylindrical parts, such as shafts and tubular components.

· Taper Turning: Machining of tapered parts, such as conical tubes and taper shafts.

· Spherical Turning: Used for machining spherical parts, such as ball valves and spherical joints.

- By Equipment Type

· Single-Axis Lathe: Ideal for simple shapes like cylindrical parts.

· Multi-Axis Lathe: Handles complex shapes and multiple tasks, reducing setups.

· Mill-Turn Machine: Combines turning and milling for complex parts in one setup.

CNC Turning Materials Available at Xielifeng

Aluminum

Feature:

Easy to machine, with good strength and corrosion resistance, making it suitable for high-precision turned parts.

Application Parts:

Shafts, valve stems, connectors.

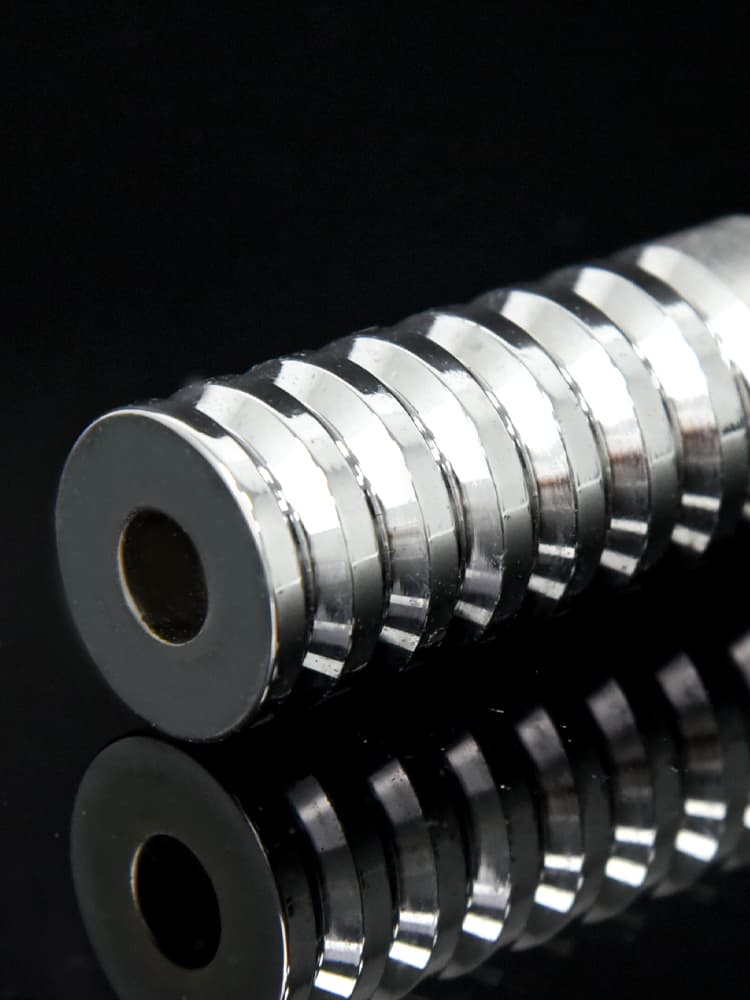

Stainless Steel

Feature:

Commonly used for parts that require high strength and corrosion resistance.

Application Parts:

Bearing rings, fasteners, valve components.

Brass

Feature:

Highly suitable for CNC turning with excellent machinability, ideal for precision turning.

Application Parts:

Fittings, bushings, valve stems.

Copper

Feature:

Copper is especially suitable for parts requiring high wear resistance.

Application Parts:

Bushings, sliding bearings, gears.

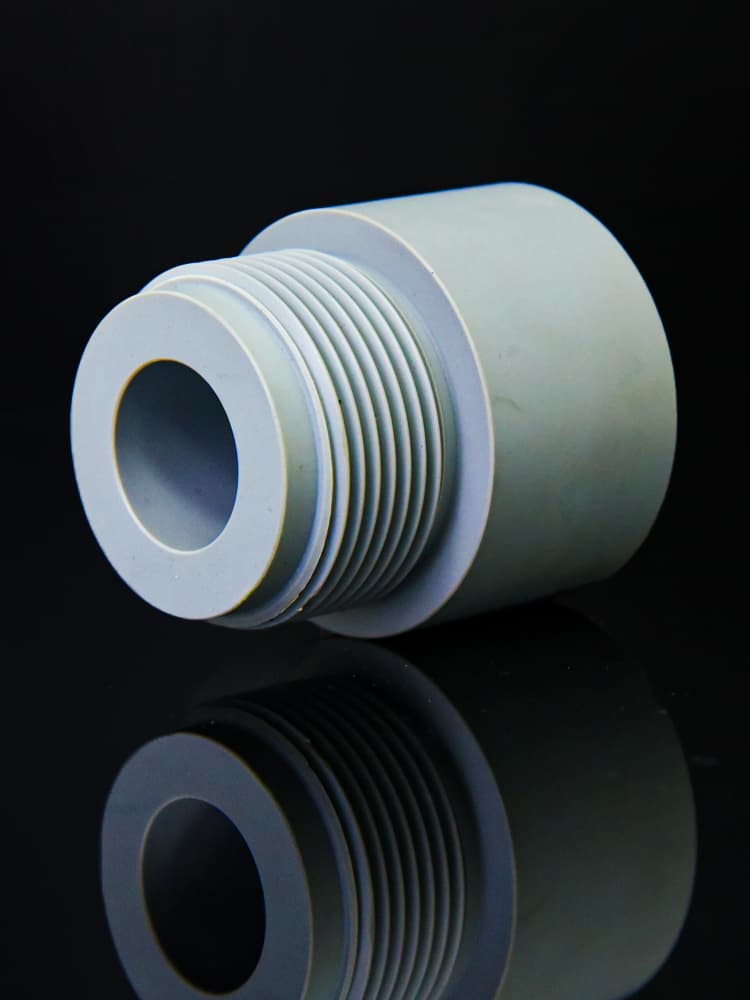

Nylon(PA)

Feature:

High strength and toughness with good wear and impact resistance.

Application Parts:

Washers, bushings, sliding components, and guides.

PTFE

Feature:

Extremely low friction coefficient, excellent chemical resistance, and high-temperature tolerance, with good machinability.

Application Parts:

Seals, valve seats, gaskets, and insulation components.

PEEK

Feature:

High strength, chemical resistance, and heat tolerance, ideal for harsh environments.

Application Parts:

Aerospace parts, semiconductor components, pump/valve parts, precision insulators.

POM

Feature:

High mechanical strength, rigidity, and excellent wear resistance, ideal for precision machining with stable dimensions.

Application Parts:

Gears, pulleys, bushings, and precision parts.

CNC Turned Parts Surface Finishes

As machined

Color: Varies by material.

Finish Purpose: Creates decorative machining patterns, light surface scratches

Sand Blasting

Color: None (Textured Surface).

Finish Purpose: Uniform matte finish, enhances surface roughness.

Anodizing

Color: Various, e.g black, red. Finish Purpose: Improve corrosion resistance, provide decorative effect.

Hardcoat anodizing

Color: Black, Gray.

Finish Purpose: Improve wear resistance and corrosion resistance.

Electroplating

Color: Various, e.g sliver, golden.

Finish Purpose: Improve appearance, increase corrosion resistance and decorativeness.

Polishing

Color: depends on material. Finish Purpose: Improve the smoothness of the workpiece surface.

Brushing

Color: Silver, Matte finish.

Finish Purpose: Create decorative effect, enhance appearance.

Powder Coating

Color: Various, e.g white, black.

Finish Purpose: Provide protective coating, improve appearance.

CNC Parts Tolerances & Standards ISO2768

Over the years, we have earned customer trust through strict quality standards and a reliable inspection system. No matter how demanding the quality requirements, we deliver flawless turned parts through scientific processes and advanced equipment.

| Permissible deviations in mm for ranges in nominal lengths | Tolerance class designation (description) | |||||||||||||||||||||

| f (fine) | m (medium) | c (coarse) | v (very coarse) | |||||||||||||||||||

| 0.5 up to 3 | ±0.05 | ±0.1 | ±0.2 | - | ||||||||||||||||||

| over 3 up to 6 | ±0.05 | ±0.1 | ±0.3 | ±0.5 | ||||||||||||||||||

| over 6 up to 30 | ±0.1 | ±0.2 | ±0.5 | ±1.0 | ||||||||||||||||||

| over 30 up to 120 | ±0.15 | ±0.3 | ±0.8 | ±1.5 | ||||||||||||||||||

| over 120 up to 400 | ±0.2 | ±0.5 | ±1.2 | ±2.5 | ||||||||||||||||||

| over 400 up to 1000 | ±0.3 | ±0.8 | ±2.0 | ±4.0 | ||||||||||||||||||

| over 1000 up to 2000 | ±0.5 | ±1.2 | ±3.0 | ±6.0 | ||||||||||||||||||

| over 2000 up to 4000 | - | ±2.0 | ±4.0 | ±8.0 | ||||||||||||||||||

Xielifeng Quality Control

Over the years, we have earned the trust of our customers through strict quality standards and a reliable inspection system. No matter how demanding your quality requirements are, we can provide flawless turned parts with our scientific inspection processes and advanced equipment.

Color Difference Meter

Purpose: Measures color difference to ensure consistency.

Rockwell Hardness Tester

Purpose: Measures material hardness, especially for metals.

2.5D Measuring Instrument

Purpose: Measures 2D dimensions, checking flatness and accuracy.

CMM - Coordinate Measuring Machine

Purpose: Precisely measures 3D dimensions and shapes of parts.

Digital Height Gauge

Purpose: Measures height and verticality of parts.

Coating Thickness Gauge

Purpose: Measures surface coating thickness.

Digital Roughness Tester

Purpose: Measures surface roughness of parts.

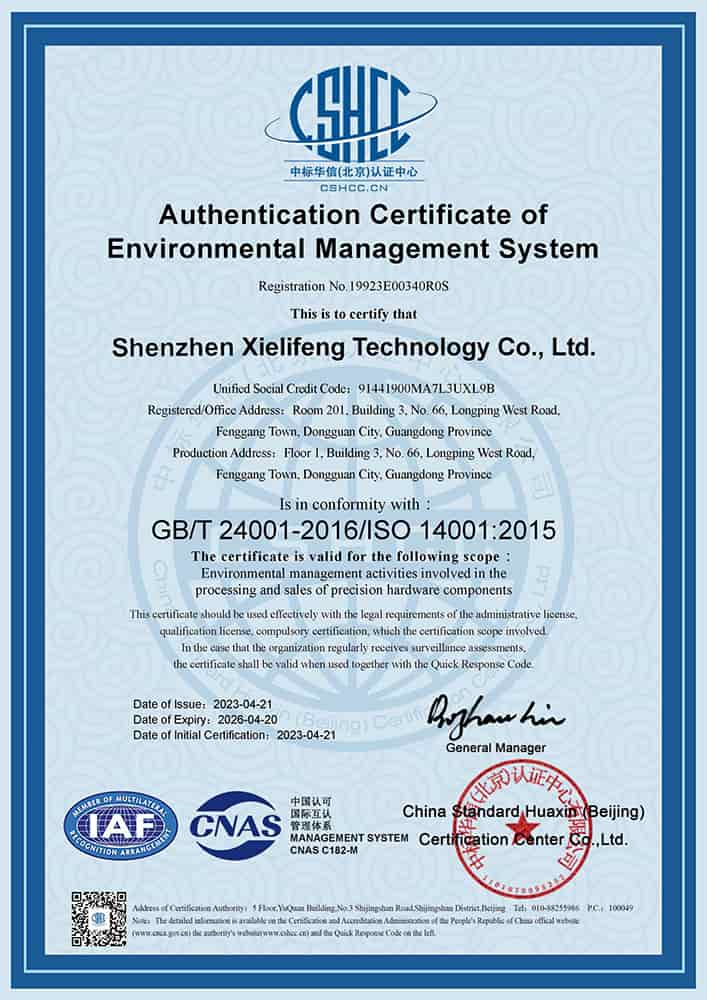

Quality Certification & Test Report

ISO 9001 and ISO 14001 certifications are key standards established by the International Organization for Standardization (ISO).

ISO 9001: Ensures high precision, reliability, and consistent quality, enhancing customer satisfaction and reducing risks.

ISO 14001: Promotes sustainable practices by minimizing environmental impact and optimizing resources.

With these dual certifications, we guarantee top product quality and eco-friendly operations, adding value for both customers and society

Xielifeng CNC Turning Parts Case Studies

How Xielifeng Works

From quotation to delivery, we provide efficient, high-quality services, making manufacturing more convenient.

01

Upload drawing

02

DFM Evaluation & Quote

03

Order Confirmtion & Production

04

Quality Inspection & Delivery

Voice from customers

We require long-term, high-consistency batch production, and their CNC turning has shown remarkable stability with virtually no variation between batches.

Katherine Hughes

Product Design Engineer

They are extremely flexible in handling urgent orders, quickly adjusting their production schedule to deliver the parts as fast as possible.

Samuel Brooks

Procurement Manager

Not only is the machining quality excellent, but deliveries are consistently on time with clear tracking, keeping our production schedule on track.

Amanda Perry

Supplier Quality Manager

Their production process is transparent and well-documented, allowing us to track quality control at every stage, ensuring the final delivered parts are flawless.

Jason Bennett

Quality Control Manager

We’ve worked together on several projects, and every time their turning quality remains consistent, with all delivered parts meeting our exact specifications.

Patrick Morgan

Motocycle Engineer

The surface finish of their turned parts is excellent, requiring little to no additional post-processing, which saves us time and costs.

Andrew Davis

Production Manager

Their technical team is very professional, offering valuable advice during part design and machining that helps us optimize our production.

Daniel Foster

Engineering Manager

They demonstrated excellent process optimization in our project, not only enhancing machining efficiency but also effectively reducing production costs.

Emily Walker

Global Sourcing Manager

Resources

-

Comparing Type II and Type III Anodizing28 Aug 2023

-

Some Lightweight Metals and Their Key Benefits21 Aug 2023

-

Custom CNC machining services in China15 Aug 2023

-

CNC machining for mold and die production in China15 Aug 2023

-

CNC machining for medical devices in China15 Aug 2023

-

The Role of CNC Machining in Electronics and Consumer Goods15 Aug 2023