Machining PEEK

PEEK (Polyether ether ketone) is a high-performance thermoplastic material that is commonly used in machining applications. It stands for Polyetheretherketone and is known for its excellent mechanical properties, chemical resistance, and high thermal stability.

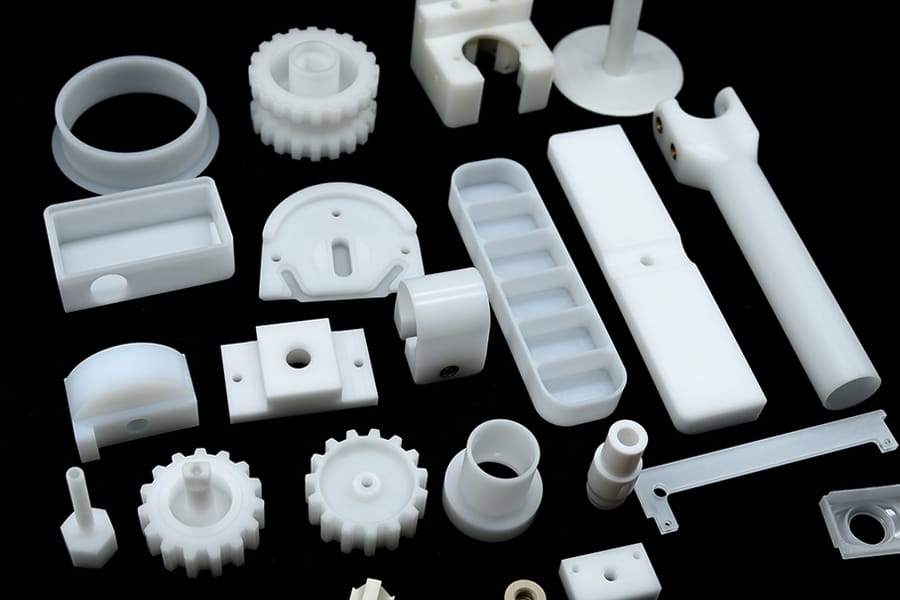

Machining PEEK requires specialized equipment and tools due to its high strength and low thermal conductivity. The most common machining processes used for PEEK include milling, turning, drilling, and tapping.

When machining PEEK, it is important to carefully select the cutting parameters such as cutting speed, feed rate, and cutting depth, as excessive heat generation can cause the material to melt or degrade. Coolant or cutting fluid is often used during machining to reduce heat and extend tool life.

PEEK is known for producing long, stringy chips during machining, which can be difficult to manage and can cause issues with chip evacuation. Proper chip evacuation techniques, such as using appropriate cutting tools and cutting strategies, are essential to ensure smooth machining operations.

Post-machining, PEEK parts may require additional finishing operations such as deburring or polishing to achieve the desired surface finish and dimensional accuracy.

Overall, machining PEEK requires expertise and attention to detail to ensure optimal results. We provide three common ways to machining PEEK: CNC machining peek, peek injection molding and 3D printing PEEK.

PEEK ‘s applications

PEEK is a versatile engineering plastic that offers excellent mechanical, thermal, and chemical properties. It is commonly used in various industries for a wide range of applications. Some of the key applications of PEEK parts include:

- Aerospace: PEEK is utilized in aircraft and spacecraft components due to its high strength-to-weight ratio, excellent resistance to chemicals and extreme temperatures, and low outgassing properties. It is commonly used in structural components, seals, bushings, fittings, and electrical connectors.

- Automotive: PEEK finds application in the automotive industry for components that require high heat resistance, chemical resistance, and durability. It is used in engine parts, fuel systems, cooling systems, electrical connectors, and sensors.

- Electronics: PEEK is used in electronic components such as connectors, sockets, insulators, and substrate materials. Its high dielectric strength, low moisture absorption, and resistance to chemicals make it suitable for these applications.

- Medical: PEEK is extensively used in the medical industry for various applications, including surgical instruments, implants, dental devices, and prosthetics. It is biocompatible, has excellent strength and stiffness, and can withstand repeated sterilizations, making it ideal for medical applications.

- Oil and Gas: PEEK is utilized in the oil and gas industry for downhole tools, pump components, seals, and other high-temperature and high-pressure applications. It offers excellent resistance to chemicals, corrosion, and wear, making it suitable for harsh environments.

- Food processing: PEEK parts are used in food processing equipment due to their FDA compliance, chemical resistance, and high-temperature stability. They are commonly used in components such as seals, bearings, and conveyor parts.

- Semiconductor manufacturing: PEEK is widely employed in the semiconductor industry for components that require high purity, chemical resistance, and dimensional stability. It is utilized in wafer handling, chemical processing, and clean room applications.

- Electrical and electronics: PEEK is used in various electrical and electronic applications, including cable insulation, electrical connectors, coil formers, and high-temperature connectors. Its electrical insulating properties and resistance to high temperatures make it suitable for these applications.

In addition to these, PEEK is also used in the chemical processing, telecommunications, defense, and sporting goods industries, among others. The versatility and performance of PEEK make it a popular choice for numerous demanding applications.

More about PEEK

PEEK, or polyether ether ketone, is a high-performance thermoplastic known for its exceptional mechanical properties and resistance to various harsh environments. Here are the key characteristics of PEEK:

-

High temperature resistance: PEEK can withstand continuous exposure to temperatures up to 260°C (500°F), making it suitable for use in high-temperature applications where other plastics would fail.

-

Mechanical strength: PEEK has excellent mechanical properties, including high tensile strength, rigidity, and toughness. It also has a low coefficient of friction, making it wear-resistant and ideal for applications that require moving parts or high load-bearing ability.

-

Chemical resistance: PEEK is highly resistant to a wide range of chemicals, including acids, bases, fuels, and solvents. It is often used in aggressive chemical environments where other materials would degrade or react with the chemicals.

-

Electrical properties: PEEK has excellent electrical insulation properties, making it suitable for applications requiring electrical conductivity or insulation.

-

Flame resistance: PEEK has inherent flame-resistant properties and meets many flammability standards, making it suitable for use in applications requiring fire resistance.

-

Biocompatibility: PEEK is biocompatible and can be used in medical implants and devices. It has been used in orthopedics, dental implants, and spinal fusion devices.

-

Dimensional stability: PEEK retains its dimensional stability even at high temperatures, maintaining its shape and mechanical properties over a wide range of operating conditions.

-

Ease of processing: PEEK can be easily processed using various techniques, including injection molding, extrusion, and machining. It can also be reinforced with fillers to enhance specific properties.

-

Weight-to-strength ratio: PEEK has a high strength-to-weight ratio, meaning it can offer high-performance properties while being relatively lightweight compared to other metals or materials.

Overall, the combination of high temperature resistance, mechanical strength, chemical resistance, and ease of processing makes PEEK a versatile material used in various industries, including aerospace, automotive, electronics, oil and gas, and medical sectors.