Brass & Cooper CNC Machining

Engineered for Performance, Ready for Your Project

24/7 Technical Support

97.8% Customer Satisfaction

ISO 9001, ISO 14001 Certified

All uploads are secure and confidential. Learn more.

IOS 9001

IOS 14001

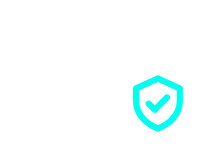

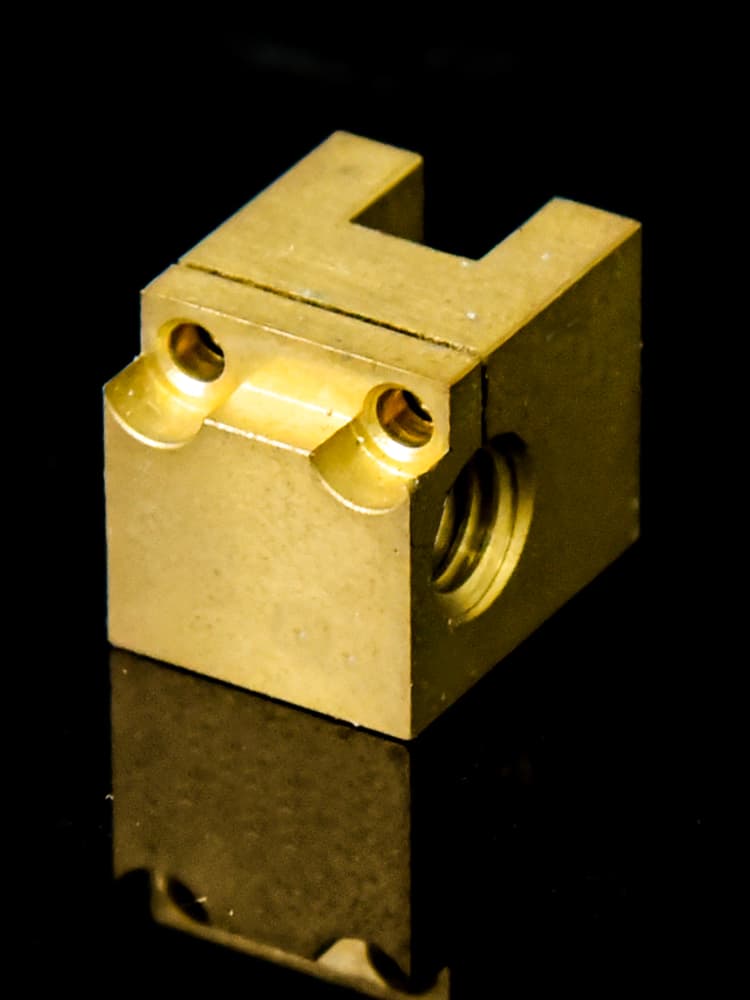

Brass

An alloy of copper and zinc, offers excellent workability and electrical and thermal conductivity, making it ideal for mechanical parts, electrical connectors, and decorative items.

Description

Application Industries: Electrical, Construction, Decorative, Automotive Manufacturing

Advantages: Good machinability, excellent thermal and electrical conductivity, decorative properties

Weaknesses: High cost, lower hardness, prone to oxidation

Features

Price: $$$$

Maximum Part Size:

236“ x 118” x 24“ (6,000×3,000 x 610 mm)

Delivery Time: 2-15 working days

Brass&Cooper

Brass, an alloy of copper and zinc, is prized for its golden-yellow hue, good conductivity, corrosion resistance, and machinability.

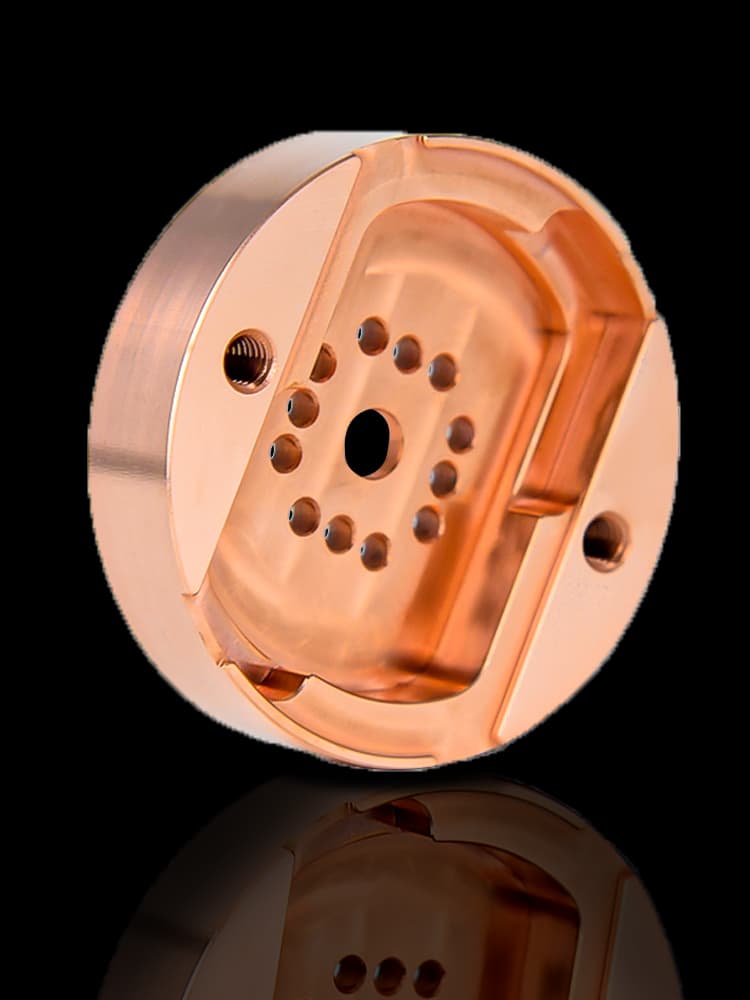

Copper is known for its reddish luster, high conductivity, corrosion resistance, and plasticity, with added antibacterial benefits for specific industries.

| Material | Material Model | Feature | Application Parts | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Brass | C18700 | High conductivity, good thermal conductivity | Electrical connectors | |||||||||||

| Brass | CuZn39Pb3 | Good machinability and workability, easy to process | Gears, Valves | |||||||||||

| Brass | H59 Brass | Good mechanical properties, easy to process | Gears, Valves, Components | |||||||||||

| Brass | HPb60-2 Brass | High lead content, easy to cut, good machinability | Rivets, Fasteners | |||||||||||

| Brass | H62 Brass | Uniform composition, good machinability | Decorative parts, Water heater parts | |||||||||||

| Brass | H63 Brass | Good plasticity, good machinability | Electrical connectors, Switches | |||||||||||

| Brass | H70 Brass | Good mechanical properties, good corrosion resistance | Springs, Connectors | |||||||||||

| Brass | HPb59-3 | High lead content, easy to cut, good machinability | Gears, Shafts | |||||||||||

| Copper | C14500 | High conductivity, good thermal conductivity | Electrical connectors | |||||||||||

| Copper | T2 Copper | High conductivity, good thermal conductivity | Wires, Cables | |||||||||||

CNC Brass & Cooper Parts surface treatment

Electroplated

Brushed

Passivated

| Finishes Option | Finishes Description | Finishes Color | Finishes Purpose |

|---|---|---|---|

| Default Surface | This is the surface finish that results directly from the machining process without any post-processing. It may have visible tool marks and is not typically very smooth. | Various (depends on material) | Basic finish, cost-effective |

| As machined | Parts are machined and deburred, sharp edges are chamfered. Visible machining marks, light surface scratches. | Various (depends on material) | Machining Decorative Patterns |

| Bead Blasting | A cold working process to improve fatigue life by bombarding the surface with spherical media. | None (textured surface) | Improve fatigue life, enhance surface strength |

| Sand Blasting | A surface treatment process using compressed air to propel abrasive material against a surface for cleaning or roughening. | None (textured surface) | Clean surface, increase roughness |

| Electrophoretic | A coating technology that applies an organic or inorganic coating to a metal surface through an electrochemical process. | Various (including black white, red, green, champagne, blue) | Provide decorative effect, improve corrosion resistance |

| Electroplating | Electrochemical deposition of a metal coating onto the surface of a part to improve appearance and resistance to corrosion. | Various (depends on plating material) | Improve appearance, increase corrosion resistance |

| Electropolishing | Electrochemical polishing to smooth the surface, improving brightness and reducing roughness. | Mirror finish | Improve smoothness, enhance brightness |

| Chrome Plating | Applying a layer of chromium to a metal part to increase wear and corrosion resistance. | Silver | Improve wear and corrosion resistance |

| Nickel Plating | Applying a layer of nickel to a metal part to improve corrosion resistance and appearance. | Silver | Improve corrosion resistance, enhance appearance |

| Gold Plating | Applying a layer of gold to a metal part to improve conductivity, corrosion resistance, and provide decorative effects. | Gold | Improve conductivity, enhance corrosion resistance, provide decorative effect |

| Silver Plating | Applying a layer of silver to a metal part to improve conductivity and corrosion resistance. | Silver | Improve conductivity, enhance corrosion resistance |

| Tin Plating | Applying a layer of tin to a metal part, often used to prevent oxidation and improve solderability. | Silver | Prevent oxidation, improve solderability |

| Zinc Plating | Applying a layer of zinc to a metal part to improve corrosion resistance. | Silver | Improve corrosion resistance |

| Laser Marking | Using a laser to mark the metal surface, providing permanent identification. | Various (depends on material) | Provide permanent identification |

| Cleaning | Using various methods to clean the metal surface, removing contaminants and impurities. | None (depends on material) | Remove contaminants, improve surface quality |

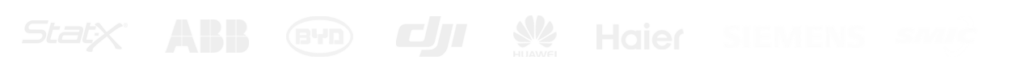

CNC Machined Brass & Cooper Parts Case Study

Brass Classification by Zinc Content

α Brass: Zinc content ≤ 37%, good plasticity, ideal for cold working (cold rolling, drawing, stamping).

α+β Brass: Zinc content 37%-45%, high strength and wear resistance, suitable for hot working (forging, extrusion).

| Brass Type | Brass Model | Feature | Application Parts | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| α Brass | H59 Brass | Good mechanical properties, easy to machine | Gears, valves, fasteners | |||||||||||

| α Brass | H62 Brass | Uniform strength and plasticity | Decorative parts, water supply fittings | |||||||||||

| α Brass | H63 Brass | Good plasticity and mechanical properties | Electronic components, connectors | |||||||||||

| α Brass | H70 Brass | High strength, good plasticity | Gaskets, screws | |||||||||||

| α Brass | HPb59-3 Brass | High lead brass, easy to machine, good wear resistance | Valves, bearings | |||||||||||

| α+β Brass | HPb60-2 Brass | High lead brass, easy to machine, good corrosion resistance | Screws, structural parts | |||||||||||

| α+β Brass | CuZn39Pb3 | High mechanical strength, good wear resistance, heat-processable | Bearings, gears | |||||||||||

Brass Classification by Use

Free-cutting brass contains lead for improved machinability, ideal for high-speed processing. Corrosion-resistant brass includes tin or aluminum for better protection in corrosive environments. Decorative Brass offers a good appearance and surface finish for decorative items.

| Material Use | Brass Model | Feature | Application Parts | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Free Cutting Brass | HPb59-3 Brass | High lead brass, easy to machine, good wear resistance | Valves, bearings | |||||||||||

| Free Cutting Brass | HPb60-2 Brass | High lead brass, easy to machine, good wear resistance | Screws, structural parts | |||||||||||

| Wear-Resistant Brass | CuZn39Pb3 | Good mechanical properties and wear resistance, easy to machine | Gears, valves | |||||||||||

| Decorative Brass | H59 Brass | Good mechanical properties, easy to machine, suitable for decoration | Gears, valves, fasteners | |||||||||||

| Decorative Brass | H62 Brass | Uniform strength and plasticity, suitable for decorative parts | Decorative parts, water supply fittings | |||||||||||

| Decorative Brass | H63 Brass | Good plasticity and mechanical properties, suitable for decoration | Electronic components, connectors | |||||||||||

| Decorative Brass | H70 Brass | High strength, good plasticity, suitable for making precision decorative parts | Gaskets, screws | |||||||||||

Order Process Custom Brass & Cooper Parts

01

Upload drawing

02

DFM Evaluation & Quote

03

Order Confirmtion & Production

04

Quality Inspection & Delivery