Rapid Prototype and Rapid Prototyping Service China

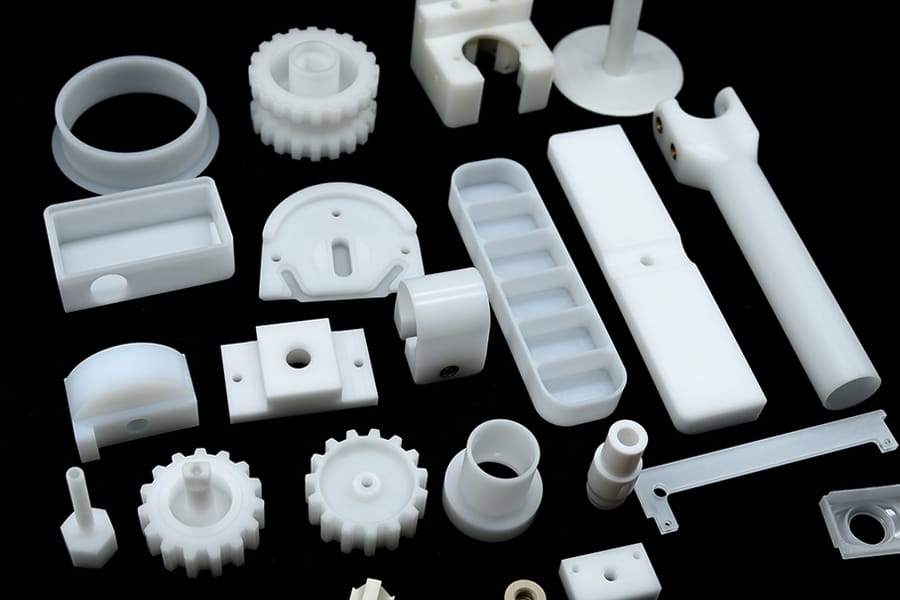

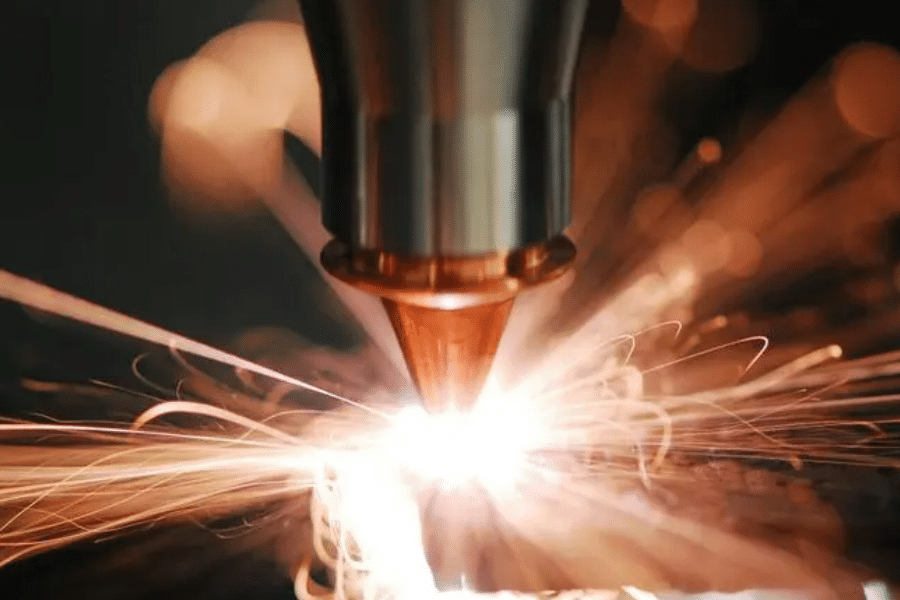

What is rapid prototype A rapid prototype is a quick, simplified version or model of a product, system, or application that is built to test and validate its functionalities and design concepts. It is typically used in the early stages of development to gather feedback and make iterative improvements before investing more time and resources […]

Rapid Prototype and Rapid Prototyping Service China Read More »