How to Improve CNC Machining Efficiency

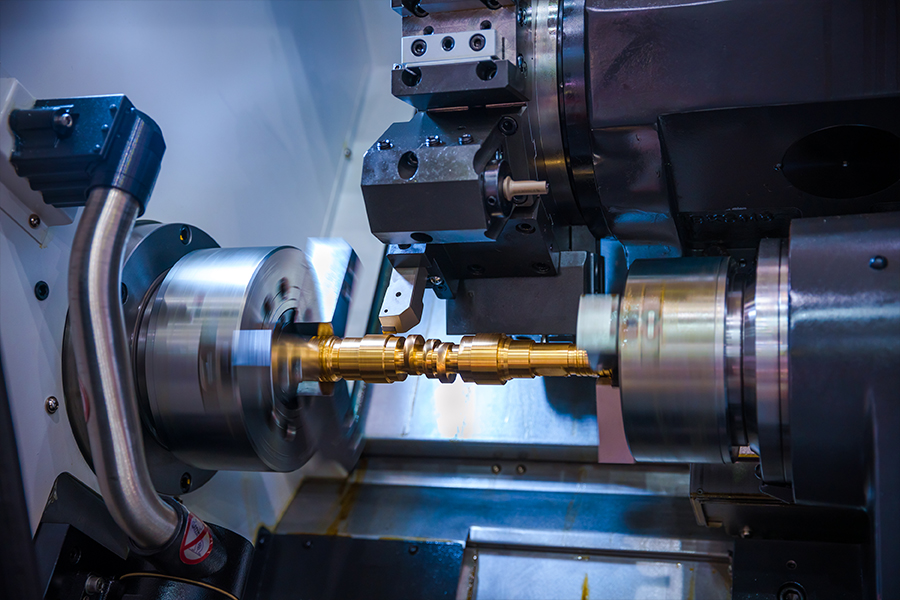

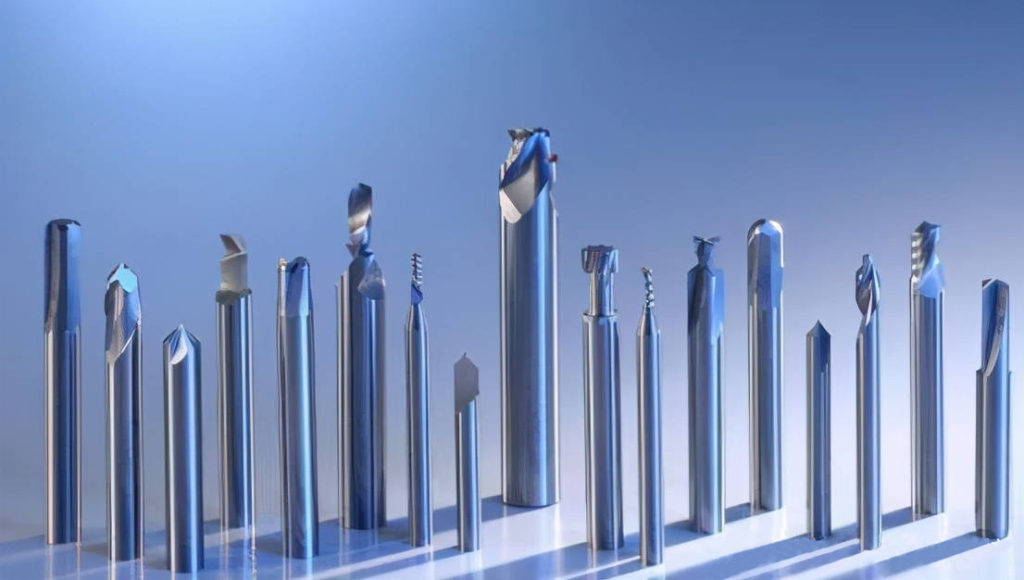

The CNC machining center adopts a CNC machine tool with its own tool magazine and automatic tool change, which can realize continuous processing of multiple processes by one clamping. In recent years, CNC multi-axis machining centers have developed rapidly due to reducing errors and improving part accuracy and machining efficiency. Improving the production efficiency of […]

How to Improve CNC Machining Efficiency Read More »