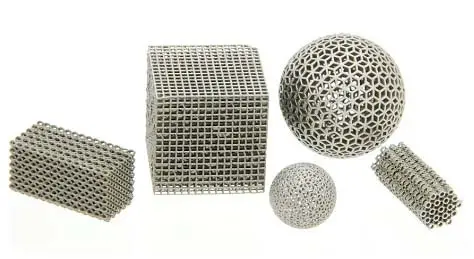

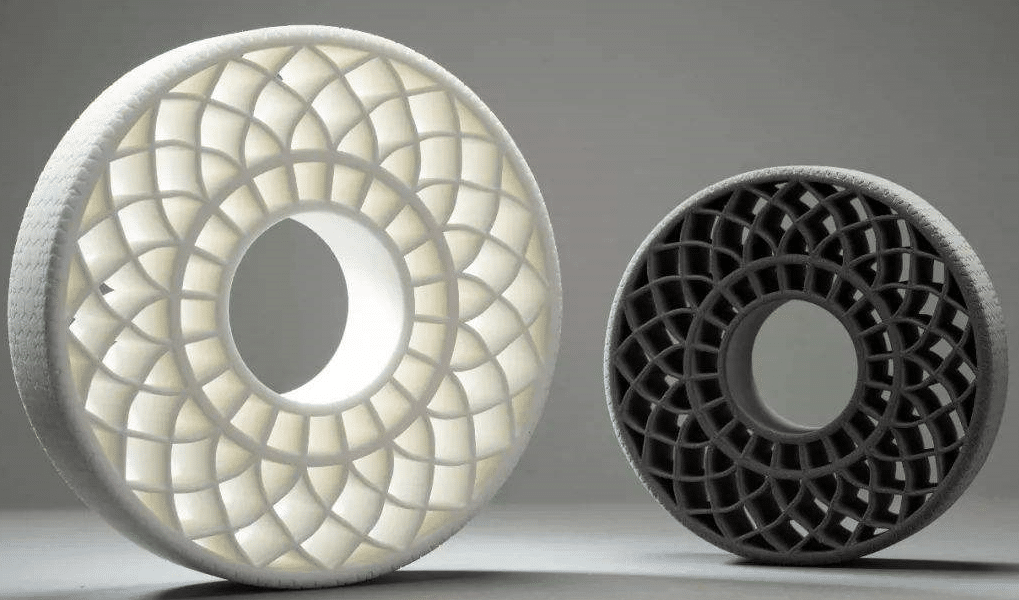

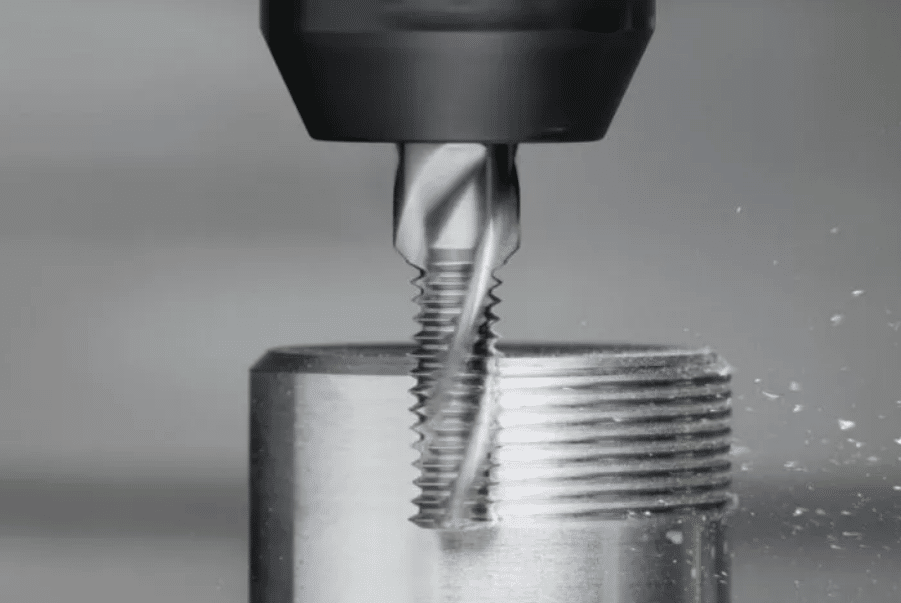

Surface Finish Methods for 3D Printing Parts

3D Printing parts are common now, we can see many metal and plastic 3D printed parts frequently. For the surface treatment of 3D printed parts, do you know several methods? Here xielifeng tech will introduce you 6 common methods. Sandpaper polishing Sandpaper is the most common grinding tool. Water should be added before grinding to […]

Surface Finish Methods for 3D Printing Parts Read More »