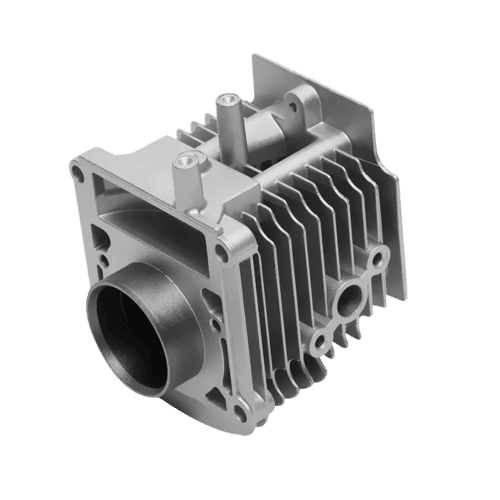

Aluminum die casting

Aluminum die casting is a manufacturing process in which molten aluminum is injected under high pressure into a steel die to produce complex and detailed components. The die is designed to form the shape and exact dimensions of the part being manufactured. The molten aluminum is then pressed into the die cavity to take on the shape of the mold and rapidly solidifies to form a finished part.

This process is commonly used to make parts for automotive, aerospace, and appliance industries due to its durability, light weight and ability to produce high-quality parts with tight tolerances. The process also allows for mass production which can significantly reduce costs and increase efficiency. Aluminum die casting is an effective way to produce components with good mechanical properties and high precision manufacturing.

Aluminum die casting process

Aluminum die casting process is a manufacturing process used to create complex shapes and parts using high-pressure injection of molten aluminum into a steel mold or die. The following steps are involved in the process:

Mold preparation: The die or mold is cleaned, lubricated, and heated to the desired temperature to ensure proper casting flow.

Molten aluminum injection: The molten aluminum is injected into the mold cavity under high pressure.

Solidification: The molten aluminum cools and solidifies within the mold cavity.

Ejection: The die casting machine opens and ejects the solidified part or casting from the mold.

Trimming: Excess metal and flash are trimmed or removed from the casting.

Surface treatment: The castings are then cleaned, deburred, and treated to improve their surface finish and integrity.

Aluminum die casting provides several advantages including high production rates, dimensional accuracy, and the ability to create complex shapes with fine details. It is commonly used in the production of automotive parts, household appliances, and various industrial components.

Aluminum die casting tolerance

Aluminum die casting tolerance refers to the allowable deviation from the specified dimensions, weight, and other requirements for aluminum die cast parts. Tolerances are an important consideration in the manufacturing process to ensure that the product meets the required specifications. The following are some factors that can affect the tolerance of aluminum die cast parts:

Material properties: The properties of the aluminum alloy used in the die casting process can affect the tolerance of the finished part.

Tooling design: The design of the die cast tooling can affect the dimensional accuracy and repeatability of the parts produced.

Process variables: Various process variables, such as melting temperature, injection pressure, and cooling rate, can affect the dimensional accuracy of the parts.

Part geometry: The complexity of the part’s geometry can affect the achievable tolerance, as well as the location and magnitude of any deviations from the specified dimensions.

Typically, the tolerances for aluminum die cast parts are specified in terms of linear dimensions, angles, and surface finishes. The tolerances can vary depending on the specific application and the requirements of the customer. It is important to work with an experienced manufacturer who can provide high-quality aluminum die cast parts that meet the required tolerances.