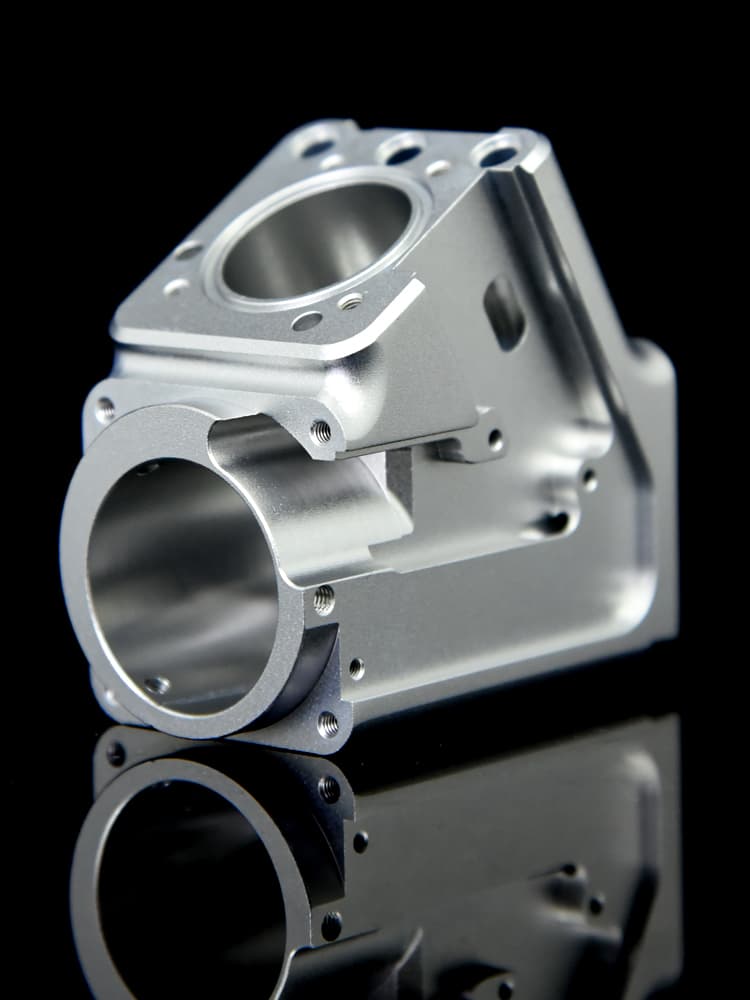

CNC Aluminum Parts Materials Selection Guide

50+ CNC Aluminum Alloys Materials

30+ Aluminum Surface Treatments

Advanced 5-Axis Aluminum Machining

All uploads are secure and confidential.* Learn More

IOS 9001

IOS 14001

Aluminum

Aluminum is a lightweight, soft metal with good electrical and thermal conductivity. Aluminum has excellent corrosion resistance and will not be eroded by air, water, or many chemicals. It is also one of the metals that can be recycled, which is suitable for environmental protection. Due to its lightweight and good strength properties, aluminum is widely used in various fields.

Description

Application Industries: Aerospace, Automotive Manufacturing, Construction, Electronics, Packaging, etc.

Advantages: Easy to machine, good thermal conductivity, corrosion-resistant, recyclable, various surface treatment options.

Weaknesses: Low hardness and strength, low wear resistance, low melting point.

Features

Price: $$

Maximum Part Size:

236“ x 118” x 24“ (6,000×3,000 x 610 mm)

Delivery Time: 2-15 working days

Common CNC Aluminum Alloys Materials

| Material Name | Main Alloy Elements | Strength | Corrosion Resistance | Weldability | Applications (Industry & Parts) | Cost |

|---|---|---|---|---|---|---|

| AL6061-T6 | Al, Mg, Si, Cu | ★★★ | ★★ | ★★★ | Bicycle frames, motorcycle parts, mobile phone shells, car parts, camera frames | $ |

| AL7075 | Al, Zn, Mg, Cu | ★★★★ | ★ | ★ | Aerospace parts, bicycle parts, motorcycle parts, high-stress parts | $$ |

| AL6063-T5 | Al, Mg, Si | ★★ | ★★★ | ★★★ | Construction materials, furniture, lighting fixtures, electronic components | $$$ |

| AL6082 | Al, Mg, Si | ★★★ | ★★ | ★★★ | Aerospace parts, automotive, shipbuilding, food processing equipment | $ |

| AL5052 | Al, Mg | ★★ | ★★★★ | ★★★★ | Marine environments, fuel tanks, pressure vessels, electronic enclosures | $$ |

| AL6061-T651 | Al, Mg, Si, Cu | ★★★ | ★★ | ★★★ | Aerospace parts, bicycle frames, motorcycle parts, mobile phone shells, camera frames | $$ |

| AL2024 | Al, Cu, Mg | ★★★ | ★ | ★ | Aerospace structures, military vehicles, high-stress components | $$ |

| AL2017 | Al, Cu, Mg, Mn | ★★★ | ★ | ★★ | Aerospace parts, screws, industrial applications, tool manufacturing | $$$ |

| AL5754 | Al, Mg | ★★ | ★★★★ | ★★★★ | Automotive body panels, shipbuilding, chemical industry, food processing equipment | $$ |

| AL1060 | Al | ★ | ★★★ | ★★★ | Electrical applications, chemical equipment, food industry, architectural decorations | $$ |

| AL6061 | Al, Mg, Si, Cu | ★★ | ★★ | ★★★ | Construction materials, automotive parts, aerospace applications, general structural use | $ |

| AL6061-T5 | Al, Mg, Si, Cu | ★★ | ★★ | ★★★ | Bicycle frames, motorcycle parts, mobile phone shells, camera frames | $$ |

| AL5050-H14 | Al, Mg | ★★ | ★★ | ★★★★ | Marine environments, fuel tanks, pressure vessels, electronic enclosures | $$ |

| AL5251 | Al, Mg | ★★ | ★★★ | ★★★ | Traffic signs, tools, marine environments, pressure vessels | $$ |

| AL4032 | Al, Si, Cu, Mg, Ni | ★★★ | ★ | ★ | Automotive engine parts, aerospace components, industrial tools | $$ |

| AL5083 | Al, Mg | ★★★ | ★★★ | ★★★★ | Shipbuilding, pressure vessels, cryogenic applications, chemical industry | $$$ |

| AL6060 | Al, Mg, Si | ★★ | ★★★ | ★★★ | Structural applications, automotive, furniture, lighting fixtures | $$ |

| AlCuMgPb | Al, Cu, Mg, Pb | ★★★ | ★ | ★★ | Machining parts, structural components, high-strength applications | $$ |

| AL6065 | Al, Mg, Si | ★★ | ★★ | ★★★ | Structural components, construction materials, industrial tools | $$ |

| AlMgSi 0.5 | Al, Mg, Si | ★★ | ★★★ | ★★★ | Construction materials, automotive parts, general structural use | $$ |

| MIC-6 | Al, Cu, Mn, Si, Mg | ★★ | ★★ | ★★ | Precision tooling, heavy-duty applications, inspection equipment, modeling tools | $$ |

CNC Aluminium Parts Surface Treatment

Machined

Sandblasted

Oxidized

Blackened

Plating

Polished

Brushed

Powder Coating

| Finishes Option | Finishes Description | Finishes Color | Finishes Purpose | Price |

|---|---|---|---|---|

| Default Surface | This is the surface finish that results directly from the machining process without any post-processing. It often shows visible tool marks and lacks smoothness. | Various (depends on material) | Basic finish, cost-effective | $ |

| As machined | Parts are machined and deburred, sharp edges are chamfered. Visible machining marks, light surface scratches. | Various (depends on material) | Machining Decorative Patterns | $$ |

| Polishing | Polishing refers to a process using mechanical, chemical or electrochemical effects to reduce the surface roughness of the workpiece to obtain a bright and smooth surface. | Various (depends on material) | Improve the smoothness of the workpiece surface | $$ |

| Bead Blasting | A cold working process to improve fatigue life by bombarding the surface with spherical media. | None (textured surface) | Improve fatigue life, enhance surface strength | $$ |

| Sand Blasting | A surface treatment process using compressed air to propel abrasive material against a surface for cleaning or roughening. | None (textured surface) | Clean surface, increase roughness | $$ |

| Brushing | A machining process, parts are brushed using abrasive brushes to create a pattern of fine parallel lines on the material surface. | Silver, Matte finish | Create decorative effect, enhance appearance | $$ |

| Anodizing | An electrolytic passivation process that enhances the natural oxide layer thickness on metal surfaces. | Various (including clear, black, blue, red, green) | Improve corrosion resistance, provide decorative effect | $$$ |

| Hardcoat anodizing | An electrochemical process that creates a thick and hard protective oxide layer on the surface of aluminum products to enhance their wear resistance and corrosion resistance. | Black, Gray | Improve wear resistance and corrosion resistance | $$$ |

| Black Oxide | A conversion coating process to blacken ferrous metals and provide corrosion resistance. | Black | Provide decorative effect, enhance corrosion resistance | $$ |

| Alodine | A chemical process that enhances adhesion of aluminum and its alloys by forming a protective chromate conversion coating. | None, gold, silver, brown, black | Improve corrosion resistance, promote paint adhesion | $$ |

| Passivation | A chemical process to remove iron from the surface of metal and improve corrosion resistance. | None (smooth surface) | Improve corrosion resistance, increase smoothness | $$ |

| Electroplating | Electrochemical deposition of a metal coating onto the surface of a part to improve appearance and resistance to corrosion. | Various (depends on plating material) | Improve appearance, increase corrosion resistance | $$$ |

| Electropolishing | Electrochemical polishing to smooth the surface, improving brightness and reducing roughness. | Mirror finish | Improve smoothness, enhance brightness | $$$ |

| Chrome Plating | Applying a layer of chromium to a metal part to increase wear and corrosion resistance. | Silver | Improve wear and corrosion resistance | $$$$ |

| Nickel Plating | Applying a layer of nickel to a metal part to improve corrosion resistance and appearance. | Silver | Improve corrosion resistance, enhance appearance | $$$ |

| Copper Plating | Applying a layer of copper to a metal part, often used as a base layer for subsequent plating or as a conductive layer. | Copper Color | Provide base layer for additional plating, improve conductivity | $$$ |

| Gold Plating | Applying a layer of gold to a metal part to improve conductivity, corrosion resistance, and provide decorative effects. | Gold | Improve conductivity, enhance corrosion resistance, provide decorative effect | $$$$ |

| Silver Plating | Applying a layer of silver to a metal part to improve conductivity and corrosion resistance. | Silver | Improve conductivity, enhance corrosion resistance | $$$$ |

| Tin Plating | Applying a layer of tin to a metal part, often used to prevent oxidation and improve solderability. | Silver | Prevent oxidation, improve solderability | $$ |

| Zinc Plating | Applying a layer of zinc to a metal part to improve corrosion resistance. | Silver | Improve corrosion resistance | $$ |

| PVD | Physical vapor deposition (PVD) process that creates a thin film on the metal surface to improve wear and corrosion resistance. | Various colors | Improve wear and corrosion resistance | $$$$ |

| DLC Coating | Diamond-like carbon (DLC) coating that enhances the hardness and wear resistance of the metal surface. | Black | Improve hardness and wear resistance | $$$$ |

| Powder Coating | Applying a powder coating using electrostatic spray and then curing it at high temperatures to form a hard protective layer. | Various (depends on powder color) | Provide protective coating, improve appearance | $$$ |

| Painting | Applying paint to the metal surface in one or more layers to provide protection and decoration. | Various (depends on paint color) | Provide protective and decorative coating | $$ |

| Heat Treatment | Using heat to alter the physical and mechanical properties of the metal. | None (depends on material) | Improve hardness, strength, and durability | $$ |

| Laser Marking | Using a laser to mark the metal surface, providing permanent identification. | Various (depends on material) | Provide permanent identification | $$ |

| Cleaning | Using various methods to clean the metal surface, removing contaminants and impurities. | None (depends on material) | Remove contaminants, improve surface quality | $ |

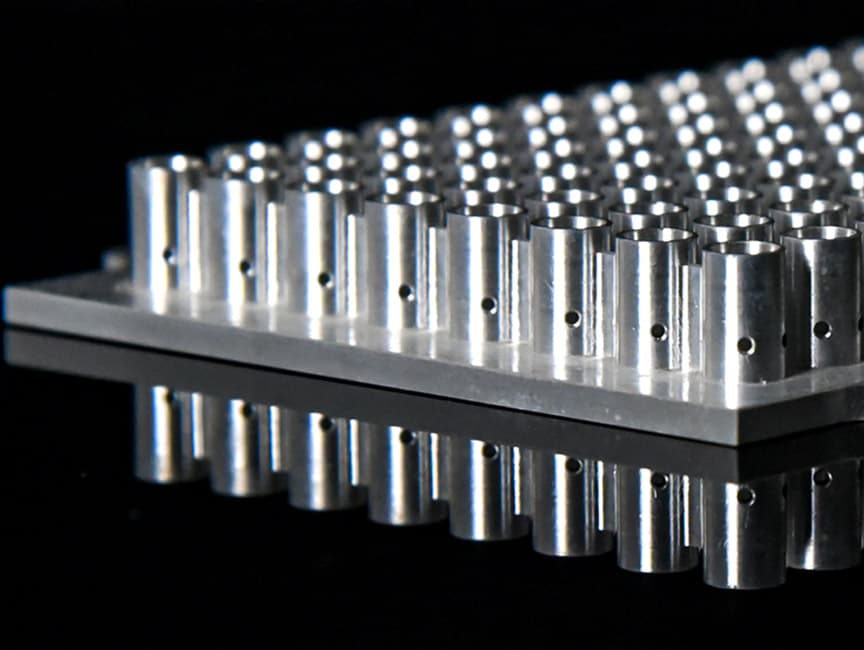

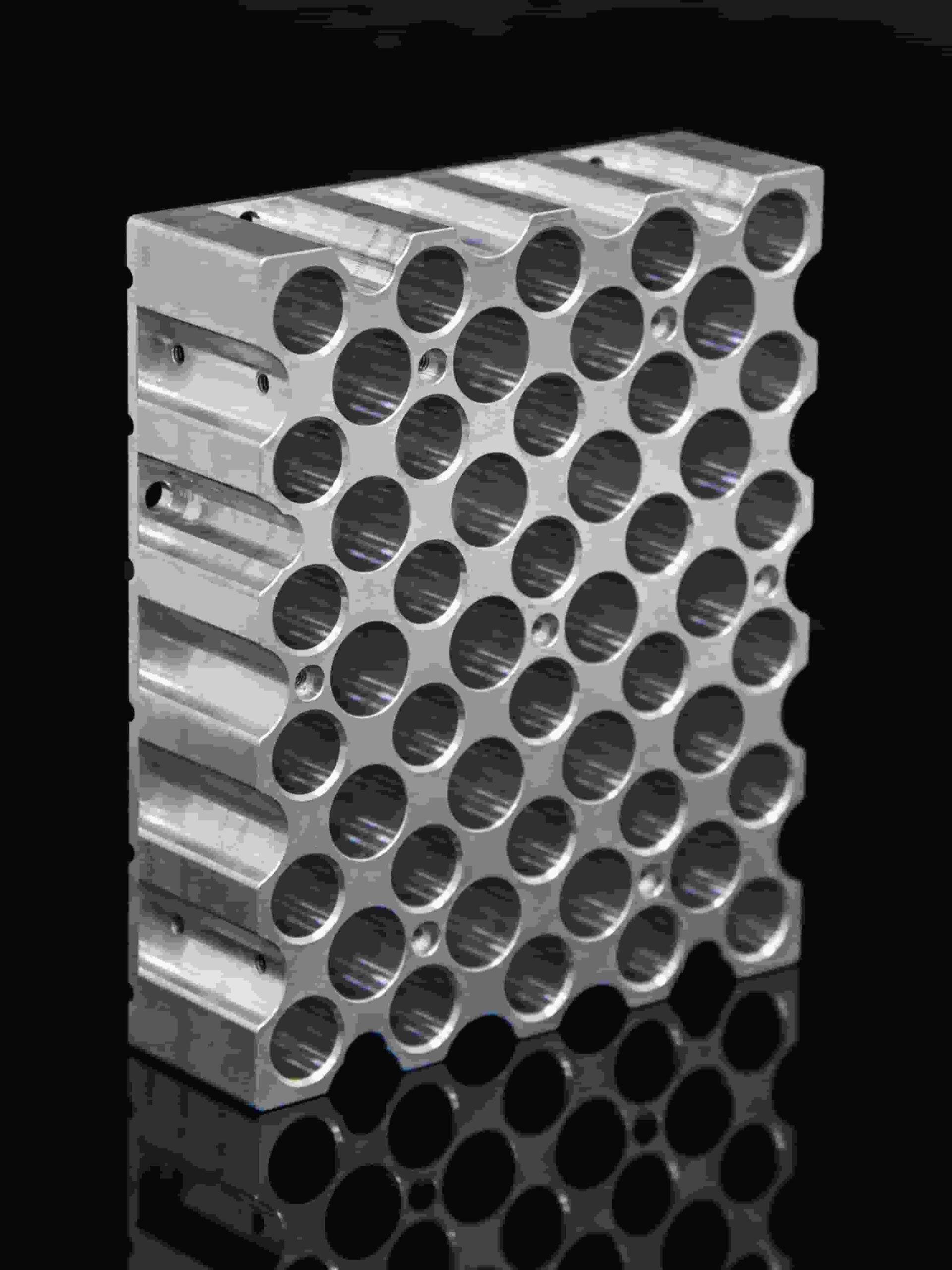

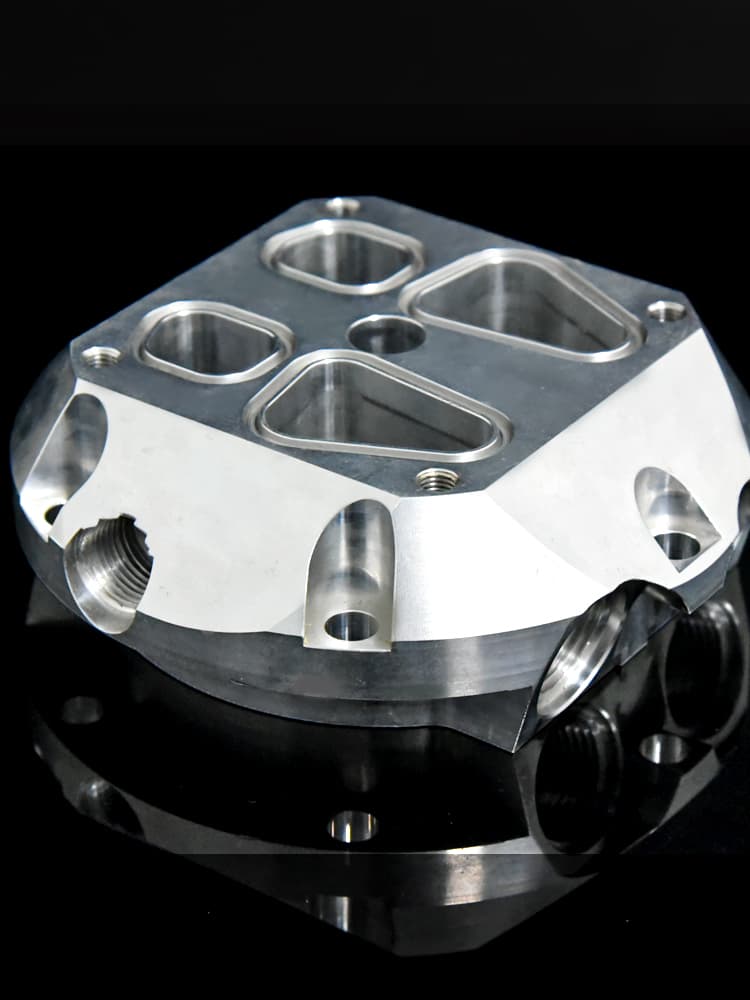

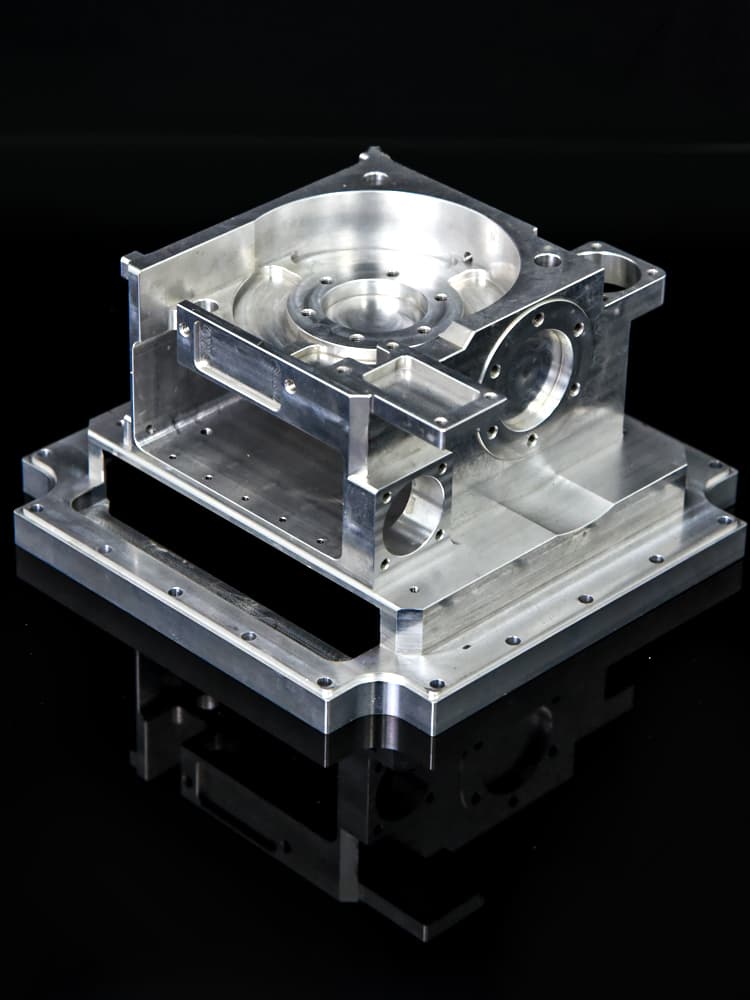

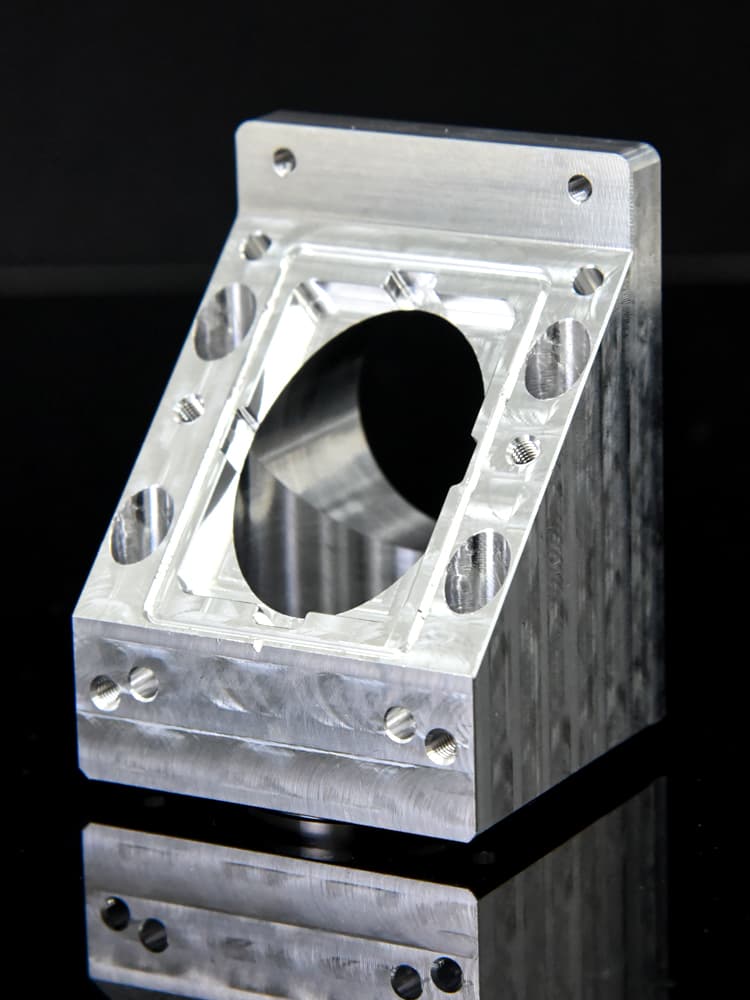

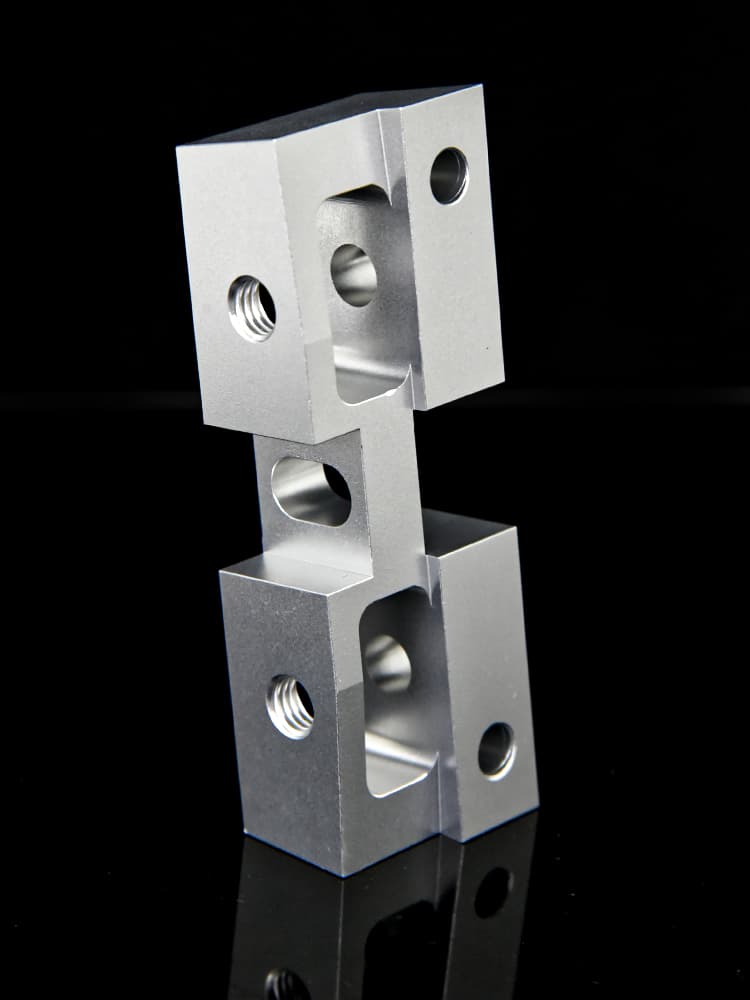

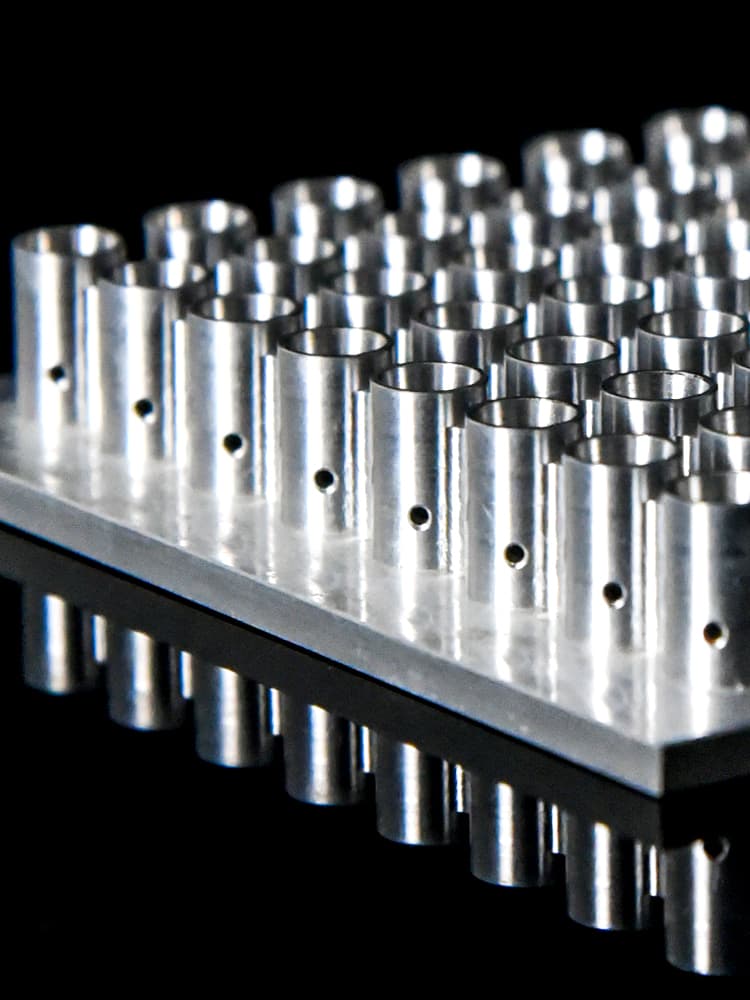

Custom Aluminum Parts Case Study

CNC Aluminum Parts Materials Selection Guide

(pure aluminum), 2000 series, 6000 series, and 7000 series. Aluminum alloys of different series have different characteristics and scopes of application

| Aluminum Alloy Series | Characteristics | Suitable For | Price | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1000 Series | Pure aluminum, excellent electrical and thermal conductivity | Electronics, food packaging, lightweight structural components in construction, etc. | $ | ||||||||||

| 2000 Series | Aluminum-copper alloys, high strength, toughness, and machinability | Aerospace, automotive parts, and other applications requiring high strength and toughness | $$$ | ||||||||||

| 5000 Series | Aluminum-magnesium alloys, excellent strength, corrosion resistance, and weldability | Construction, automotive manufacturing, shipbuilding, and other applications requiring high strength and corrosion resistance | $$ | ||||||||||

| 6000 Series | Aluminum-silicon-magnesium alloys, moderate strength, good formability, and corrosion resistance | Aerospace, automotive, shipbuilding, food processing equipment, container manufacturing, etc. | $$ | ||||||||||

| 7000 Series | Aluminum-zinc alloys, high strength, good wear resistance | Aerospace, automotive, transportation, and other applications requiring high strength and good wear resistance | $$$ | ||||||||||

Mechanical Properties

High Strength:

7075 Aluminum Alloy: Known for its extremely high strength and excellent fatigue resistance.

6061 Aluminum Alloy: Offers a good balance of strength, corrosion resistance, and machinability.

Corrosion Resistance:

5052 Aluminum Alloy: Excellent corrosion resistance, particularly in marine environments, combined with good formability.

Surface Treatments

Excellent Anodizing:

6061 Aluminum Alloy: Well-suited for anodizing, providing a durable and attractive finish.

High Gloss Surface:

6082 Aluminum Alloy: Ideal for applications requiring a high-gloss surface finish.

Wear Resistance:

7075 Aluminum Alloy: Known for its high strength and excellent wear resistance.

Other

High Cost-Performance Ratio:

6063 Aluminum Alloy: Offers a good balance of strength, formability, and corrosion resistance at an affordable price.

Mass Production:

3004 Aluminum Alloy: Suitable for large-scale production due to its excellent formability and moderate strength.

Environmentally Friendly:

1050 Aluminum Alloy: High-purity aluminum that is easily recyclable and has a low environmental impact.

Order Process of CNC Machining Aluminum Parts

01

Upload drawing

02

DFM Evaluation & Quote

03

Order Confirmtion & Production

04

Quality Inspection & Delivery