XIELIFENG

From Concept to Creation,

We Make It Happen

Creating Unmatched Value with 25+ Years of Expertise

Committed to Excellence, Trusted by 7800+ Clients Globally

Over 12 Million Parts Manufactured with Precision and Care

All uploads are secure and confidential.* Learn More

ISO 9001

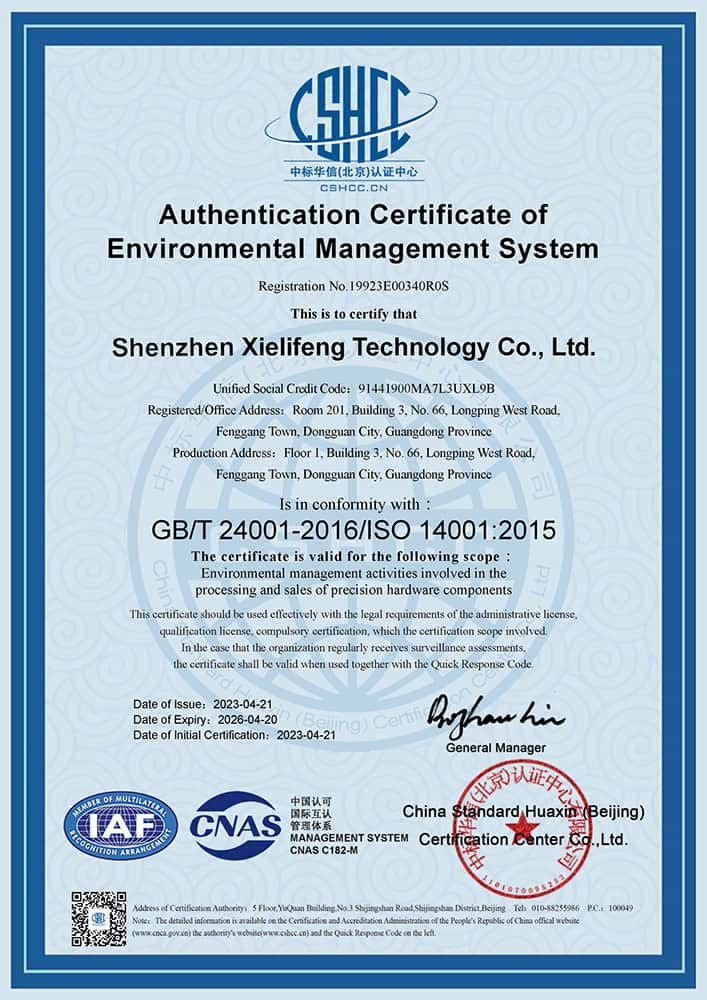

ISO 14001

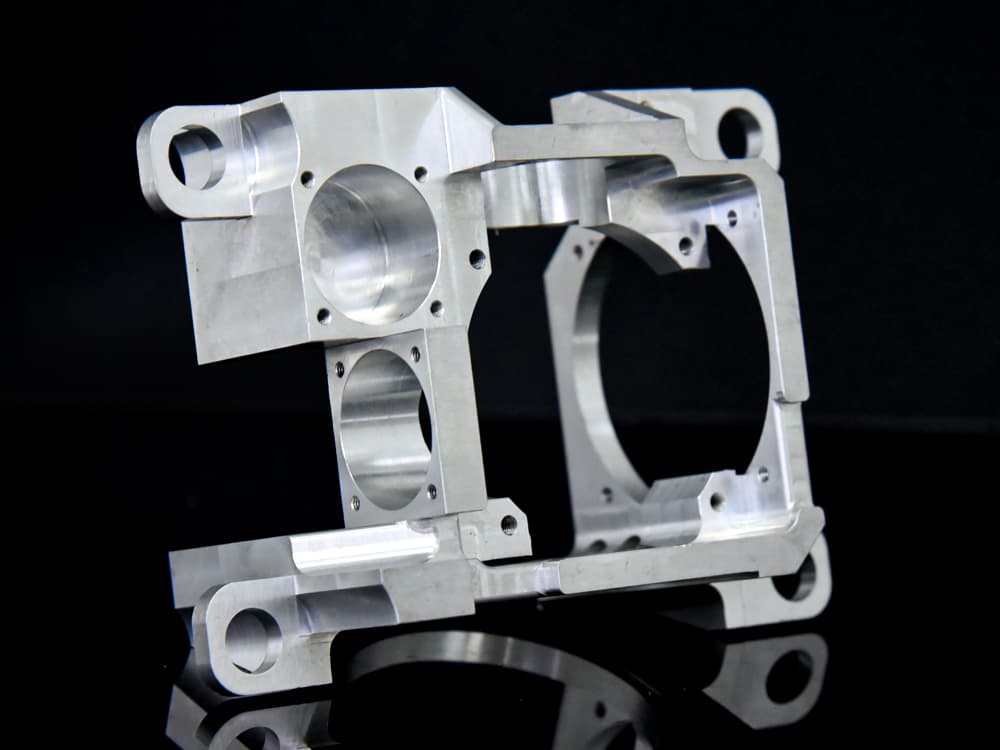

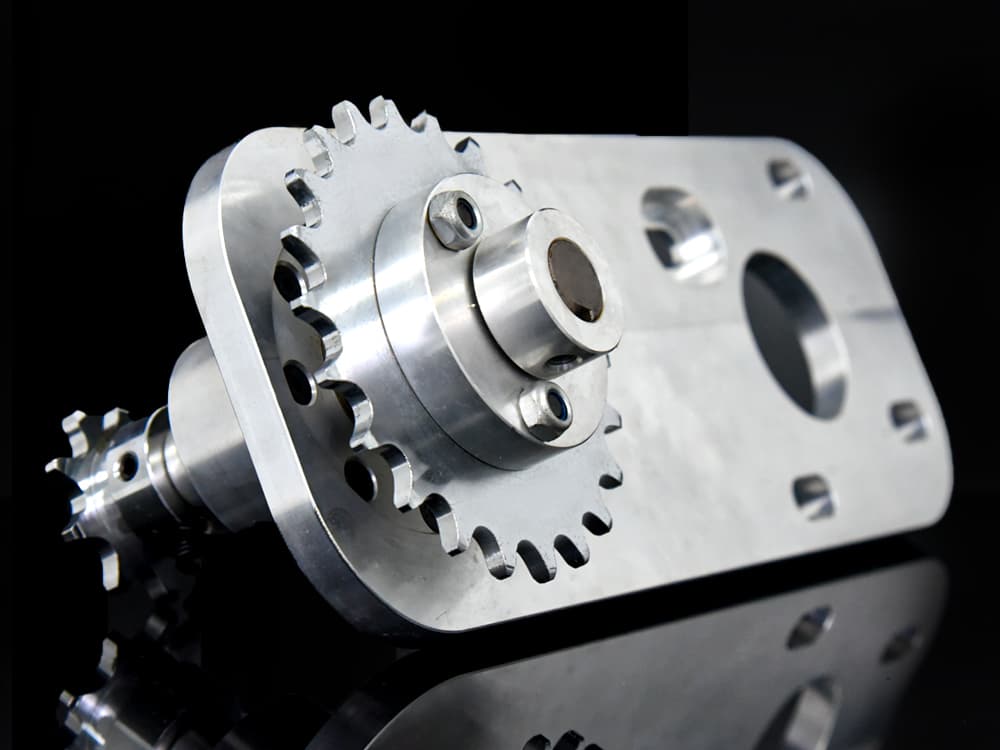

Our Story

Founded in 1999, Xielifeng has established itself as a leader in CNC precision machining industry area in China. We are committed to delivering unparalleled quality, innovation, and customer satisfaction in every custom part we produce. With a strong commitment to excellence, we have grown into a trusted partner for businesses across the globe.

Our Vision

To become the world’s leading provider of precision machining solutions, driven by innovation and excellence, creating unparalleled customer value and advancing industry standards.

25+

years of expertise in the CNC machining industry

15+

15+ industry sectors with rich experience in different fields served

9000+

Hours of monthly machining capacity, on-demand

7800+

Satisfied clients worldwide, spanning multiple industries

97.8%

On-time delivery rate,

ensuring your projects stay on schedule

XIELIFENG

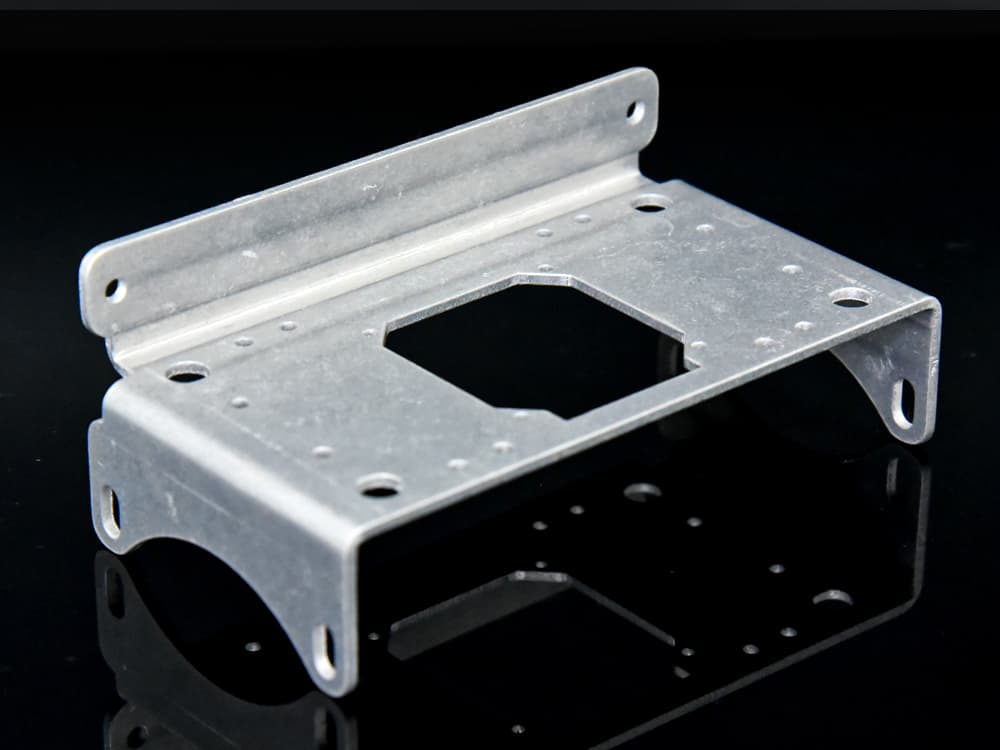

COMBINED PROCESSING

Sheet Metal

Die Casting

3D Printing

Injection Molding

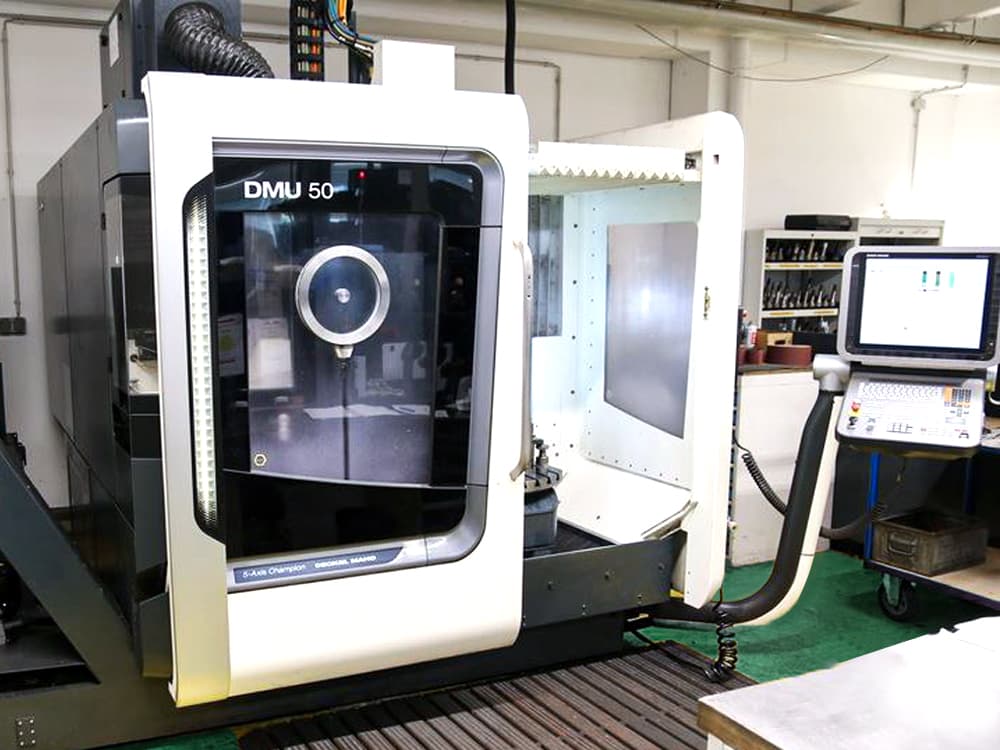

Xielifeng Machining Equipment

Our factory is equipped with advanced 5-axis machine tools, including DMG, Mazak, Haas, Okuma and Makino brands. These devices enable us to process complex parts with high accuracy and multiple angles, ensuring that each part is of the highest standard.

Xielifeng Factory in Dongguan, China

DMG 5 Axis Machining Equipment

Mazak 5 Axis Machining Equipment

MAKINO Machining Equipment

Xielifeng Professional Team

When you inquire with Xielifeng, a team of at least two experts will assist you throughout the process. Our experienced and skilled team offers flexible, efficient solutions to ensure high-quality, customized machining.

If you have preferred experts, let us know!

Rapid Prototyping Team

Business Manager: Stefen

Specializes in quick response and flexible order handling, 8 years of experience ensuring swift fulfillment of customer needs.

Engineer: Henry

Expert in rapid prototyping, skilled in advanced technologies to deliver efficient, high-quality outcomes.

Mass Customization Team

Business Manager: Peter

Over 10 years of experience specializing in handling large-volume orders, ensuring efficient production and timely delivery.

Engineer: Emily

Proficient in mass production processes and automated production line design, ensuring efficient and high-quality output.

5-Axis Machining Team

Business Manager: Crystal

Experienced in 5-axis projects, skilled in meeting customer needs, managing changes, and delivering quality solutions across industries.

Engineer: James

dept at handling the most challenging and intricate shapes with precision, committed to delivering top quality in every project.

Multi-Industry Team

Business Manager: Jenny

With 10 years of multi-industry sales experience, specializes in providing personalized solutions backed by extensive industry knowledge.

Engineer: Daniel

With 15 years of machining experience, broad expertise in handling diverse materials, and the ability to manage complex parts efficiently.

Surface Finishing Team

Business Manager: David

With 7 years of surface treatment experience, familiar with various processes to provide optimal solutions for clients.

Engineer: Benjamin

Proficient in anodizing, electroplating, and coating technologies, ensuring superior product appearance and performance.

Multi-Industry Team

Business Manager: Harry

Experienced in integrating various manufacturing processes to provide comprehensive solutions for clients.

Engineer: Sophia

Expert in sheet metal, die casting, plastic injection, ensuring seamless coordination with machining for efficient, integrated solutions.

Xielifeng Quality Control

Superior Quality Control Ensuring Precision and Reliability in Every Part

As a leader in the machining parts industry, our quality control board ensures that every product meets the highest standards. Every step, from raw materials to finished products, is meticulously monitored to guarantee consistently high quality.

Comprehensive Monitoring: Every production stage, from initial inspection to final packaging, is covered.

Accurate Testing: Utilizing advanced testing equipment and technology to ensure every part’s dimensions and tolerances meet strict standards.

Reliable Assurance: Each batch undergoes multiple quality checks, ensuring the long-term stability and reliability of the parts.

Color Difference Meter

Purpose: Measures color difference to ensure consistency.

Rockwell Hardness Tester

Purpose: Measures material hardness, especially for metals.

2.5D Measuring Instrument

Purpose: Measures 2D dimensions, checking flatness and accuracy.

CMM - Coordinate Measuring Machine

Purpose: Precisely measures 3D dimensions and shapes of parts.

Digital Height Gauge

Purpose: Measures height and verticality of parts.

Coating Thickness Gauge

Purpose: Measures surface coating thickness.

Digital Roughness Tester

Purpose: Measures surface roughness of parts.

Superior Quality Control Ensuring Precision and Reliability in Every Part

As a leader in the machining parts industry, our quality control board ensures that every product meets the highest standards. From raw materials to finished products, every step is meticulously monitored to guarantee consistent high quality.

Comprehensive Monitoring: Every production stage, from initial inspection to final packaging, is covered.

Accurate Testing: Utilizing advanced testing equipment and technology to ensure every part’s dimensions and tolerances meet strict standards.

Reliable Assurance: Each batch undergoes multiple quality checks, ensuring long-term stability and reliability of the parts.

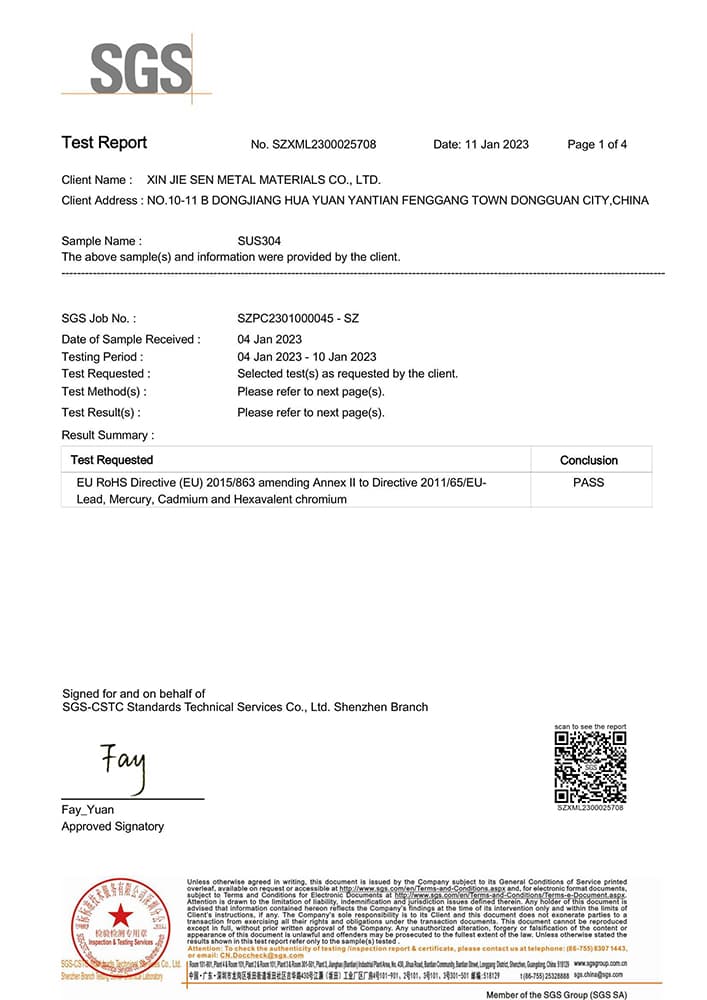

ISO 9001

ISO 14001

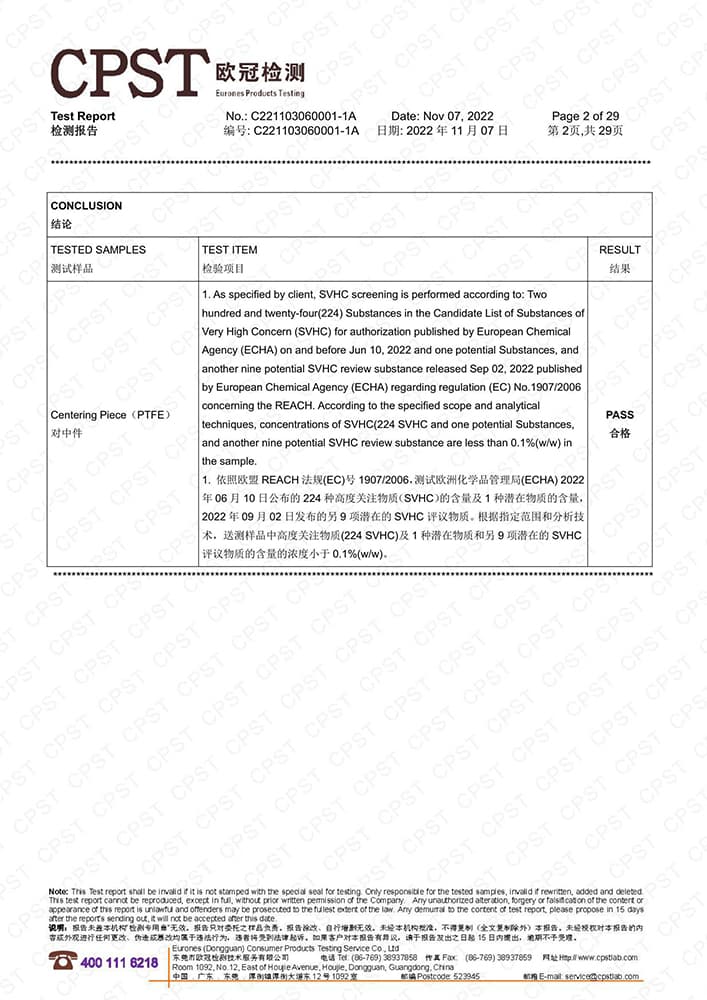

Reach

RoHs

Xielifeng Quality Control Process for CNC Parts

Xielifeng’s quality control process covers every stage from customer order to receipt of goods, ensuring each part meets the highest quality standards.

Order Confirmation

Customer Requirement Confirmation

Our team collaborates with customers to finalize needs and quality requirements, considering every detail.

Technical Evaluation and Confirmation

QE reviews drawings, confirms feasibility, and develops the initial quality control plan.

Supplier Management & Incoming Inspection

Material Supplier Evaluation

SQE evaluates and selects qualified raw material suppliers to ensure stable supply and material quality.

Incoming Material Inspection

IQC conducts chemical analysis and mechanical tests on incoming materials to ensure they meet standards.

In-Process Quality Control

Process Development & First Inspection

QE designs process flows and inspects first-article prarts, covering dimensions, shape, surface, and performance.

Process Monitoring and SPC

PQC monitors real-time data and applies Statistical Process Control (SPC) to ensure stability and consistency.

Final Parts Inspection and Packaging

Final Inspection

Performs final inspections on finished products, checking dimensions, surface, function, and performance etc.

Packaging Compliance Inspection

PQC sets packaging specs and inspects materials for compliance with standards and customer requirements.

Pre-shipment inspection and delivery

Pre-shipment Inspection

OQC conducts random checks before packaging, following standards to ensure quality during transport.

Shipment Preparation

SA Confirms shipment details with the customer to ensure timely, accurate, and safe product delivery.

Customer Feedback and Continuous Improvement

Customer Feedback Processing

SA gathers customer feedback on product quality and quickly resolves complaints and issues.

Quality Improvement

QM leads projects, analyzes data, implements improvements, and boosts quality and satisfaction.

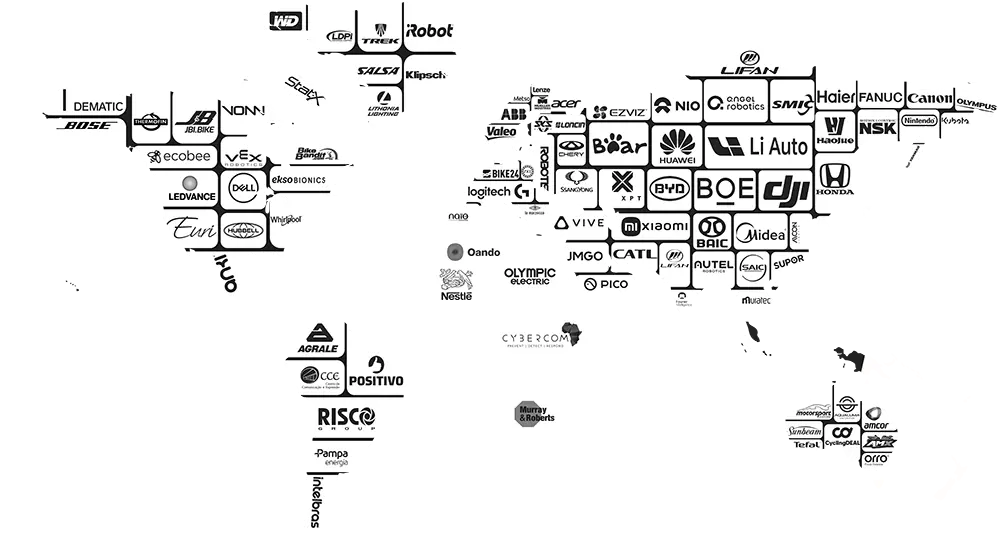

Global Partners: Trusted by Over 7,800 Clients Worldwide

What Our Customers Say

Area

Manager

Manager

Manager

Sustainable Development

How Xielifeng Works

From quotation to delivery, we provide efficient and high-quality services, making manufacturing more convenient.

01

Upload drawing

02

DFM Evaluation & Quote

03

Order Confirmtion & Production

04

Quality Inspection & Delivery