Delivering Accuracy, Speed, and Reliability in Every CNC Metal Part

Xielifeng CNC metal machining services bring together precision, expertise, and innovation. We offer end-to-end solutions, ensuring efficiency and exceptional results for every project.

All uploads are secure and confidential.* Learn More

IOS 9001

IOS 14001

CNC Machining Metal Materials List

Aluminum

Features: Lightweight, high strength, excellent thermal conductivity, corrosion resistance, and easy machinability.

Common Grades: 6061, 7075, 2024, 5052.

Applications: Aerospace, automotive components, electronic devices, medical equipment, and new energy parts.

- Precision Machining: With advanced 5-axis CNC machines and precision fixtures, we ensure aluminum parts achieve tolerances of ±0.01mm.

- Surface Finishing Capabilities: We offer anodizing, sandblasting, polishing, and other finishing options to meet high aesthetic and functional requirements.

- Efficiency and Cost Control: Optimized cutting processes minimize material waste, and our delivery cycles are 20% faster than the market average.

Stainless Steel

Features: High strength, excellent corrosion resistance, heat resistance, and easy maintenance.

Common Grades: 304, 316, 410, 17-4PH.

Applications: Food processing equipment, medical instruments, marine components, automotive parts, and household appliances.

- Overcoming Machining Challenges: With specialized cutting tools and advanced cooling techniques, we effectively address stainless steel's tendency for deformation and tool wear.

- Corrosion Resistance Assurance: Strict machining and surface treatment processes ensure parts achieve a 30% longer service life.

- Consistent Quality: 100% dimensional inspection and surface hardness testing guarantee a 99.8% acceptance rate for all parts.

Carbon Steel

Low Carbon Steel: Moderate strength, excellent ductility, ideal for light structural components.

Medium Carbon Steel: Higher strength and hardness, suitable for mechanical parts.

High Carbon Steel: High strength and hardness, ideal for tools and spring components.

Applications:Gears, shafts, structural parts, industrial machinery components, and mold.

- High Efficiency and Cost Control: Optimized cutting processes reduce material waste, lowering costs by 10%.

- Heat Treatment Capabilities: We offer quenching, tempering, and annealing processes to ensure stable part performance.

- Large-Scale Production: Capable of high-volume production, with an annual output of over 500,000 carbon steel parts and fast delivery times.

Alloy Steel

4140 Alloy Steel: High strength and wear resistance, ideal for heavy-load components.

4340 Alloy Steel: Combines toughness and hardness, suitable for aerospace and heavy industrial parts.

8620 Alloy Steel: Carburizing steel with a hard surface and tough core, ideal for gears and shafts.

- Specialized Tools and Parameter Optimization: Effectively address hardness and tool wear challenges during alloy steel machining.

- Performance Assurance: Carburizing and quenching processes extend part service life by 30%.

- Consistent Quality: 100% hardness and dimensional inspections ensure a 99.8% acceptance rate.

Tool Steel

Applications: Mold manufacturing, cutting tools, stamping dies, shafts, and wear-resistant components.

- Expertise in Difficult Materials: Extensive experience in tool steel machining ensures effective control of deformation and cracking issues.

- High Precision: Achieving machining accuracy of ±0.005mm, meeting the stringent requirements of molds and cutting tools.

Titanium

Features: High strength, low density, excellent corrosion resistance, and biocompatibility.

Common Grades:

Ti-6Al-4V: Widely used due to its strength and corrosion resistance.

Grade 2 Pure Titanium: Excellent formability and corrosion resistance.

Applications: Aerospace, medical implants, chemical processing equipment, and high-end automotive components.

- Solutions for Difficult-to-Machine Materials: We use specialized tools and optimized machining parameters to address titanium's hardness and tendency to deform.

- Optimized Surface Finishing: Offering sandblasting and oxidation treatments to enhance appearance and durability.

- High Precision and Reliability: Delivering aerospace-grade precision parts to meet the demands of high-performance industries.

Copper

C110 (Pure Copper): Exceptional electrical and thermal conductivity.

C101 (Oxygen-Free Copper): Superior conductivity, ideal for high-end electronic applications.

Applications: Electrical connectors, electronic components, heat sinks.

- High-Precision Conductive Part Machining: Dimensional tolerances controlled to ±0.005mm, ensuring stable performance for critical applications.

- Surface Finish Assurance: Polishing and optical inspection guarantee a surface finish up to Ra0.4.

- Complex Part Machining: Advanced 5-axis machining capabilities efficiently produce intricate and detailed structures.

Brass

C360 (Free-Cutting Brass): Exceptional machinability, ideal for precision machining.

C272 (Brass): Excellent ductility, suitable for stamped and decorative components.

Applications: Plumbing components, valve parts, electronic connectors, and decorative hardware.

- High Surface Finish Quality: Achieving a surface finish of up to Ra0.4, meeting the requirements for decorative and precision connectors.

- High-Efficiency Machining: Optimized tools and machining parameters increase efficiency by 20%.

- Batch Production Stability: Capable of large-scale production with a quality consistency rate of 99.8%.

Super Alloys

Features: Exceptional strength and corrosion resistance in high-temperature environments.

Common Grades: Inconel 718, Hastelloy, Monel

Applications: Aerospace engines, turbine components, and chemical processing equipment.

- Expertise in Difficult-to-Machine Materials: Extensive experience in machining Inconel, Hastelloy, and other super alloys, effectively addressing challenges of high-temperature hardness.

- High Durability and Precision: Delivering parts that meet stringent performance requirements for high-temperature and corrosive environments, with an acceptance rate of 99.8%.

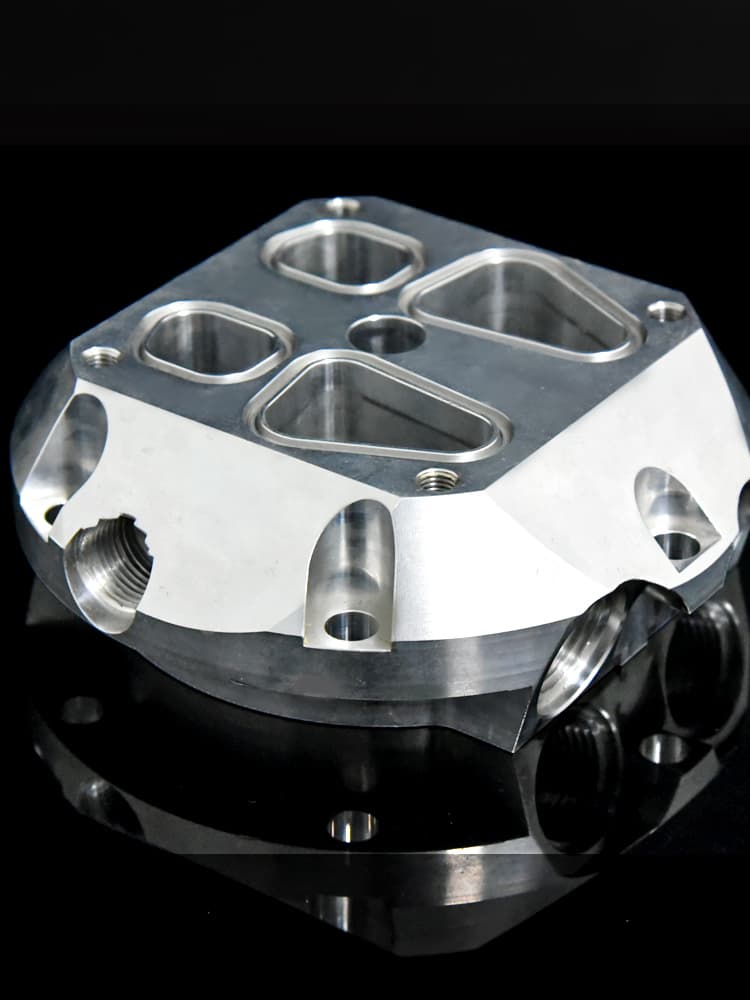

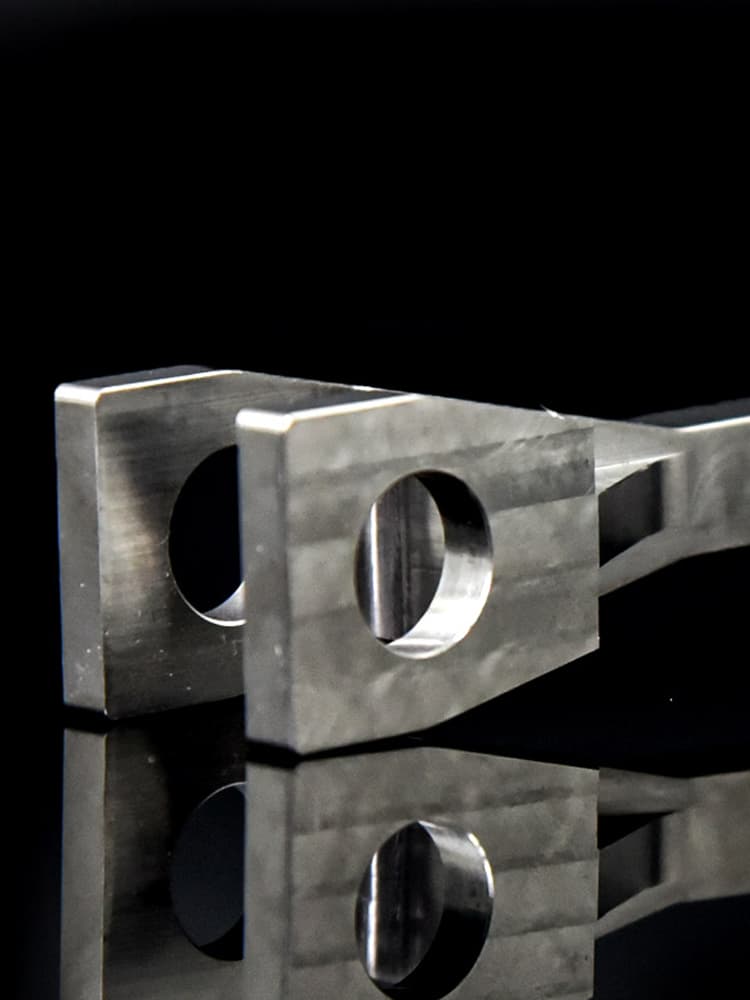

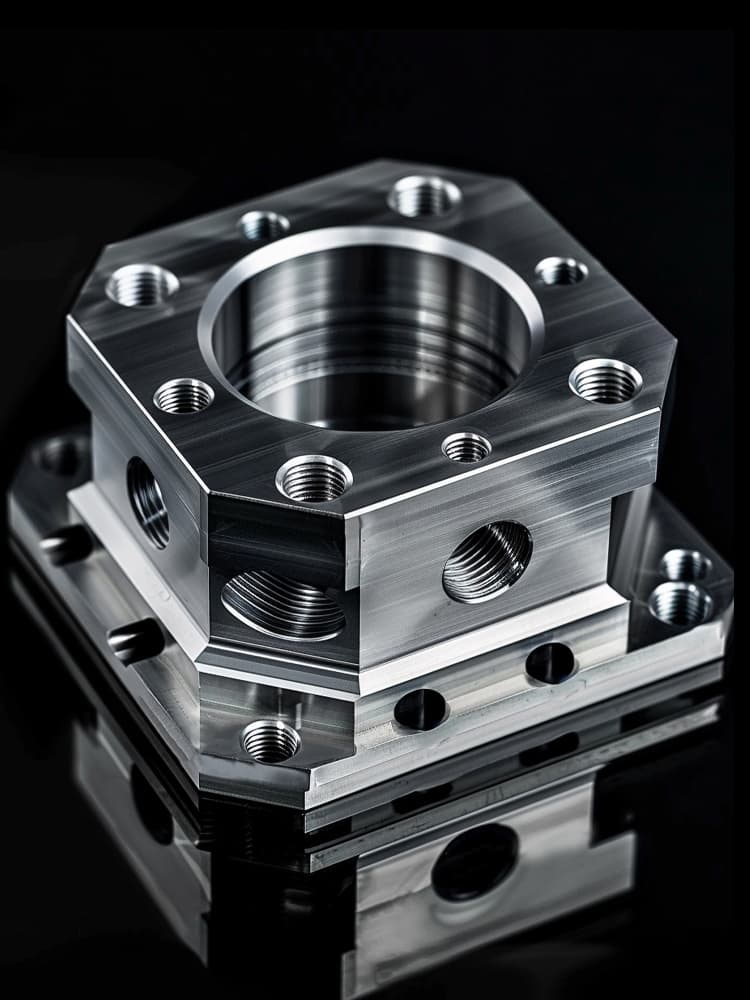

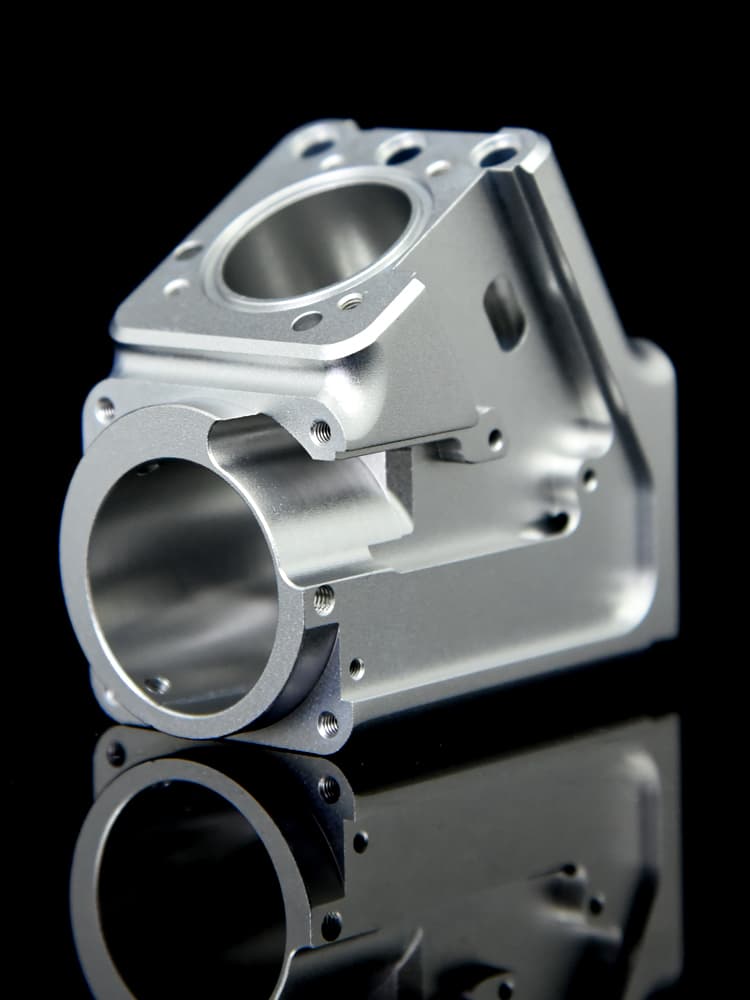

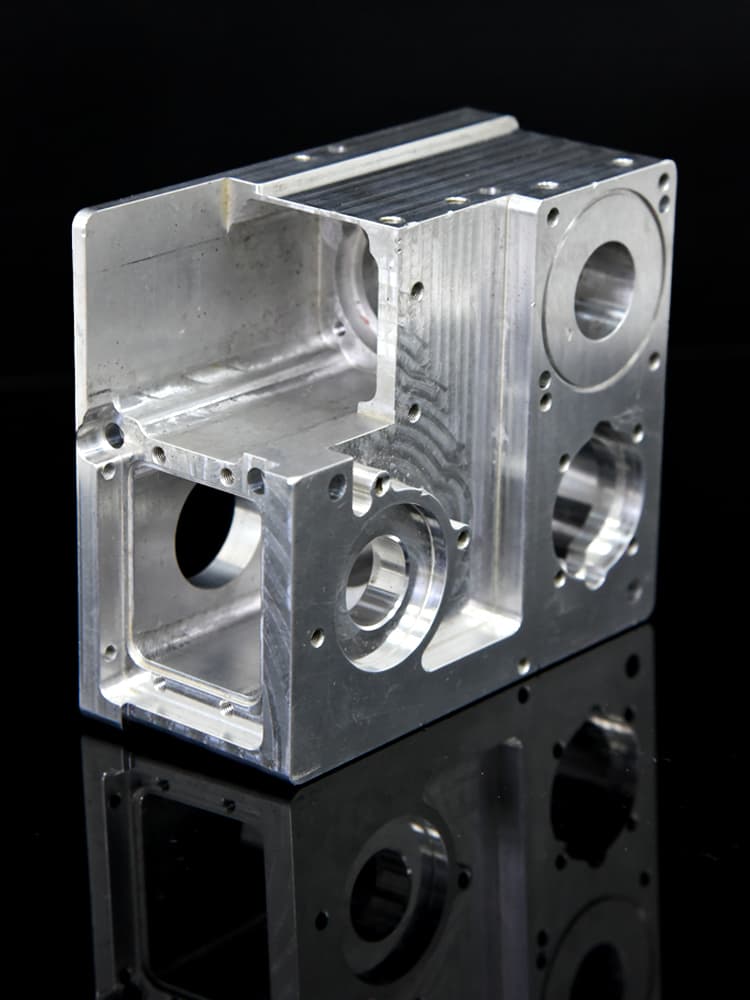

Xielifeng CNC Metals Parts Case Studies

| Features | CNC Milling Parts | CNC Turning Parts | ||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Maximum Part Size | 236" x 118" x 24" (6,000 x 3,000 x 610 mm) | 62" Length x 32" Diameter (1,575 mm Length x 813 mm Diameter) |

||||||||||||||||||||

| Minimum Feature Size | 0.020″ (0.50 mm) | 0.020″ (0.50 mm) | ||||||||||||||||||||

| Estimated Delivery Time | 3-7 working days | 3-7 working days | ||||||||||||||||||||

| Standard Tolerance | ISO 2768 MK | ISO 2768 MK | ||||||||||||||||||||

| Precision Tolerance | ±0.0002" (±0.005mm) | ±0.0002" (±0.005mm) | ||||||||||||||||||||

| Threads and Threaded Holes | Standard threads and holes available, also customizable. | Standard threads and holes available, also customizable. | ||||||||||||||||||||

| Edge Conditions | Deburring by default. | Deburring by default. | ||||||||||||||||||||

| Surface Smooth | Ra 0.4 - 1.6μm | Ra 0.4 - 1.6μm | ||||||||||||||||||||

200+

Advanced Equipment

Over 200 high-end machines, including 5-axis machining centers, supporting a wide range of metal processing.

98.9%

Quality Assurance: Comprehensive

quality inspection throughout the process, achieving a project success rate of 98.9%.

15-30%

Optimized processes and automated equipment reduce lead times by 15-30%.

5-10%

Cost Control

Process optimization and precision cutting minimize material waste, saving overall costs by 5-10%.

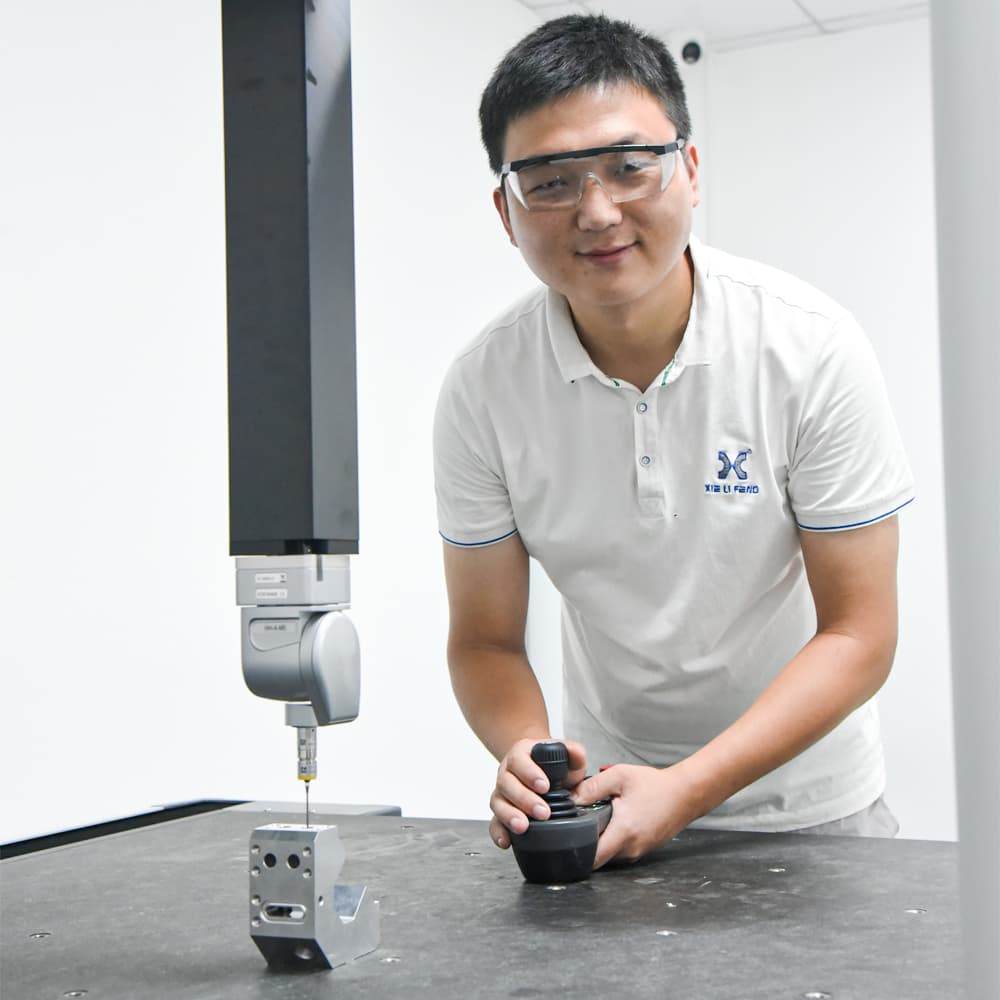

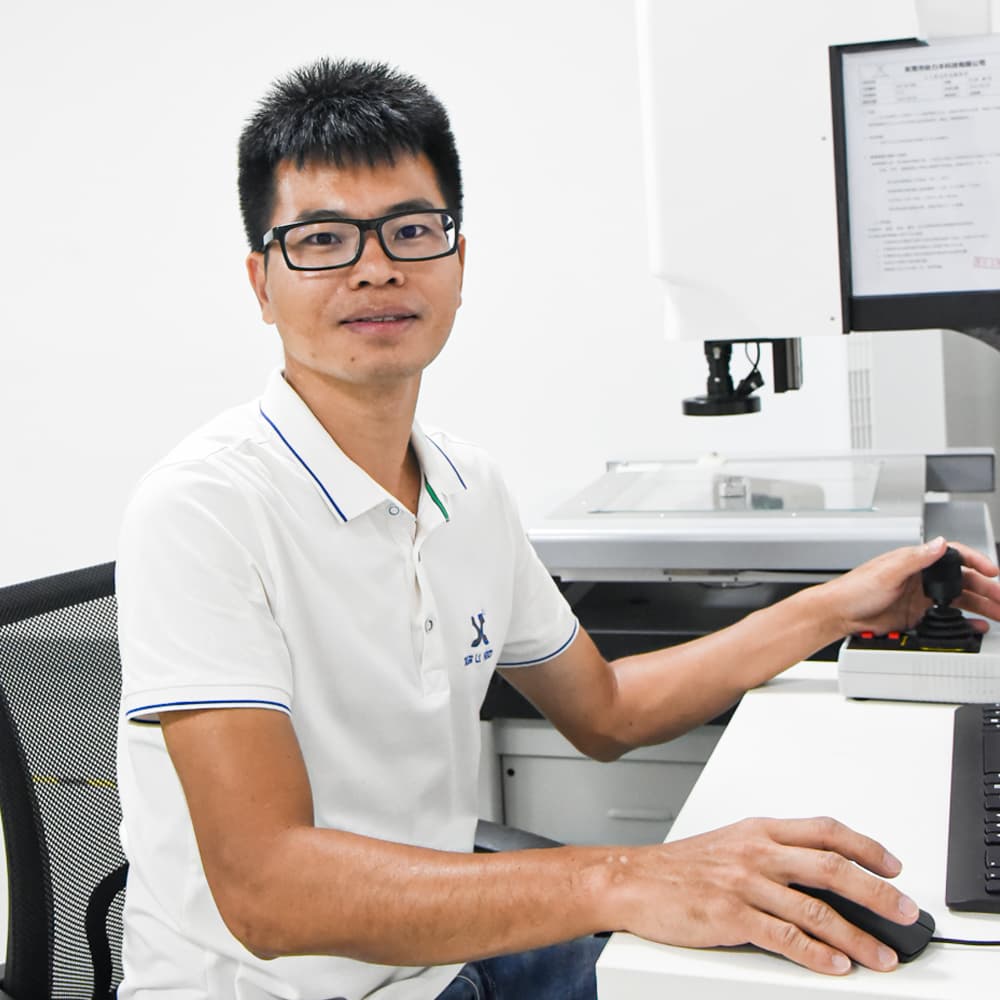

Xielifeng Professional Testing Team and Testing Equipment

At Xielifeng, our expert testing team and advanced equipment ensure top-quality machined parts. Using precision tools like CMMs, hardness testers, and surface roughness gauges, we rigorously inspect every stage—from raw material to final product—guaranteeing unmatched accuracy and reliability.

Jason | (QM) |

Quality Manager

Develops quality plans, analyzes results, and coordinates audits to ensure compliance.

Anthony | (ME) |

Material Engineer

Implements material testing, resolves performance issues, and drives material R&D.

Maria | (IQC) |

Incoming Quality Control

Inspects incoming materials, enforces quality procedures, and maintains traceable records.

Aisley | (CE) |

Calibration Engineer

Calibrates equipment, performs testing, and ensures data accuracy and equipment reliability.

Callie | (QE) |

Quality Engineerr

Conducts routine testing, ensures lab safety, and supports material analysis.

Spectrometer

Hardness Tester

CMM

Tensile Testing Machine

Ultrasonic Flaw Detector

Comprehensive Material Quality Control Process

Our six-step process ensures all raw materials meet strict quality standards before production. From supplier management and procurement to thorough inspections, testing, and data analysis, we guarantee reliable and consistent materials for precision manufacturing.

01 Material Supplier Management

We maintain strict supplier management with regular audits to ensure a steady supply of high-quality raw materials.

02 Material Procurement

We collaborate exclusively with trusted suppliers to guarantee the stability and reliability of our material sources.

03 Incoming Material Inspection

Materials are thoroughly inspected upon arrival by engineers and inspectors to verify their appearance and basic specifications.

04 Material Testing

Each batch of materials is sampled and tested using spectrometers, hardness testers, ultrasonic flaw detectors, X-ray analyzers, and CMMs.

05 Data Recording & Analysis

Inspection data is meticulously recorded and analyzed by quality inspectors to confirm compliance with required standards.

06 Results Review & Archiving

Approved materials are archived and moved into production, while non-compliant materials are returned to suppliers for corrective action.

How Xielifeng Works

From quotation to delivery, we provide efficient, high-quality services, making manufacturing more convenient.

01

Upload drawing

02

DFM Evaluation & Quote

03

Order Confirmtion & Production

04

Quality Inspection & Delivery