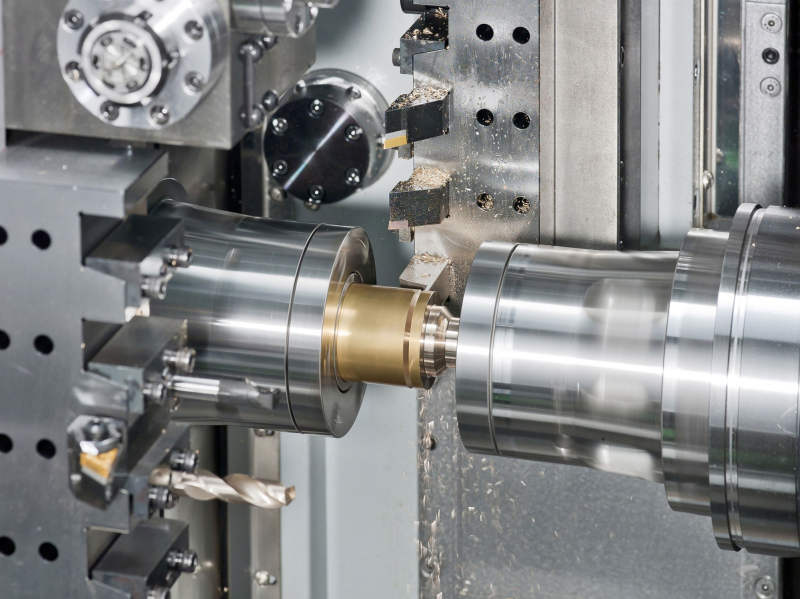

This article will show you some applications of CNC machining

The degree of numerical control of machine tools can reflect the degree of scientific and technological progress of a country. At present, many CNC technologies have been fully integrated into the machine tool equipment, which has comprehensively improved the quality and efficiency of processing. From the perspective of the currently used machine tools, CNC lathes, CNC milling machines, CNC grinding machines and machining centers all use CNC technology. The success of technology. Through computer program instructions, a wide variety of components can be fully machined, especially many irregular-shaped parts. The computer has designed the application program. Through certain parameter settings, including the parameter design of material consumption, spindle speed, process application, tool selection, etc. in the cnc machining fabrication process, a good operation program is established, and the equipment can be in the specified program. It operates, controls the processing process, and can also make adjustments according to different products.

Programming has a greater impact on machine tool equipment, which fully guarantees manufacturing accuracy and flexibility. The computer system is in command of the overall situation, and there is basically no error in the processing process, which greatly ensures the quality of the product. The computer can test each program, revise the unreasonable programs found, and transmit signals in time for errors found in the processing process, prompting the background technicians to pay attention, and make timely adjustments to the materials to avoid losses and improve processing. speed.

1. Industrial Processing Applications

The development of society is inseparable from the processing industry, which meets the needs of social life and production through processing. In the actual production process, the processing industry has played an important role. Through the transformation of numerical control technology, the speed and scale of processing can be improved, and the high-efficiency advantages of numerical control technology can be fully utilized. In the process of industrial processing, the combination of digital technology and processing technology has improved the production speed of mechanical parts assembly line, and played a role in promoting large-scale integrated production. CNC machining technology has played a role in various industries and can improve its production scale, especially in processing places with harsh environments, and can play an important role, such as food processing, chemical production, printing and paper, electrical appliances, etc. numerical technology. Through the effective use of numerical control technology, the speed and efficiency of production can be greatly improved, and manual processing and production can be completely replaced, so that the output of the operation is more. CNC machining can also ensure the safety of production, so that products that are impossible to produce can be processed by automatic equipment, ensuring the level of precision.

2.Application of CNC machining technology in piston machining

The piston is the power device for the operation of the equipment, which requires more precise processing and production, especially in terms of tolerance fit and measurement technology, so that it can form a precise fit with the bearing. CNC equipment can play a good role in piston processing and make the piston more fine. The traditional piston processing method in our country is relatively backward, and the precision of its processing is not high, and there are often large errors, which affect the operation of the equipment. However, through the application of numerical control technology, it can be well corrected in the piston processing and improve the performance of the piston. Fineness of piston machining. Piston machining is a high-precision machining process, which has a very important impact on instruments and equipment. In order to manufacture such precision instruments, it is necessary to make full use of computer programming to make piston manufacturing more convenient and reduce costs.

3. Automotive Manufacturing Applications

Cars are an inseparable tool in people’s lives, and the utilization rate is high, and people rely more on cars to travel. Whether the production level of automobiles is high or not depends entirely on the manufacturing equipment. In particular, the precision of each part of the car is very high, and the mutual cooperation must be scientific and reasonable to ensure the safety and stability of the car. Traditional automobile production requires a large amount of manual work, and mechanical processing methods are completely incompetent for the high requirements and high standards of parts. Nowadays, in the process of producing automobiles in modern enterprises, numerical control technology is fully used, which further improves the precision of automobile parts production. It can be said that CNC technology undertakes the task of machining complex parts. Numerical control technology can be designed on the computer, so that the part model can be constructed more accurately, and other parts can be connected after processing. The use of numerical control technology makes complex processes simple, promotes the development of automation and intelligence in assembly line engineering, and also reflects high flexibility and efficiency. For some small-scale production, the application of numerical control technology can improve production efficiency, ensure the speed of replacement of automotive products, and promote the continuous improvement of the automotive industry. CNC machining also promotes the development of virtual manufacturing technology and flexible manufacturing technology, making automobile production methods more advanced and modern.

4. Coal mining applications

Coal plays a very important role in economic construction and social development, but coal mining is extremely dangerous. A little carelessness will lead to dangerous accidents, resulting in casualties. Therefore, the comprehensive application of numerical control technology in coal mining can significantly improve safety. Modern scientific and technological mining technology has brought new vitality to the coal mining industry. The tools and environment of coal mining are very important. If the tools are unreasonable, the workload will increase; if the environment is unsafe, accidents will occur. The application of numerical control technology solves these problems and promotes the process of automation and intelligence in the coal mining industry.

5. Weapon Development and Application

Weapons are related to national defense and security. Only by comprehensively improving the quality of production can the quality of weapons be ensured. Through the combination of numerical control processing technology and traditional weapon manufacturing technology, the production quality of processing has been comprehensively improved, and the needs of national defense and training have been fully met. The processing of various parts and components also greatly reduces errors, improves the accuracy of processing, and improves the modernization development speed of my country’s weapon equipment manufacturing.

Related keywords: cnc machining aluminum parts, machine parts cnc machining parts, lathe cnc machining, cnc machining fabrication, customized cnc machining