5 Axis CNC Machining Services

Precision Complex Parts, Unmatched Efficiency

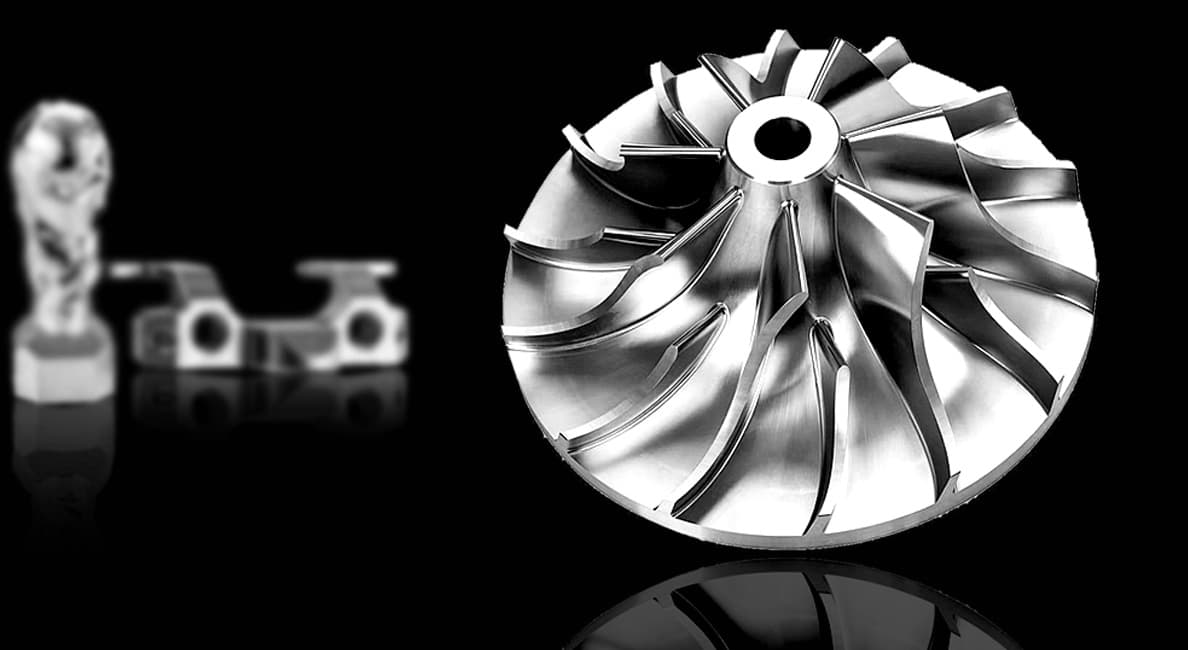

Turbine Blades

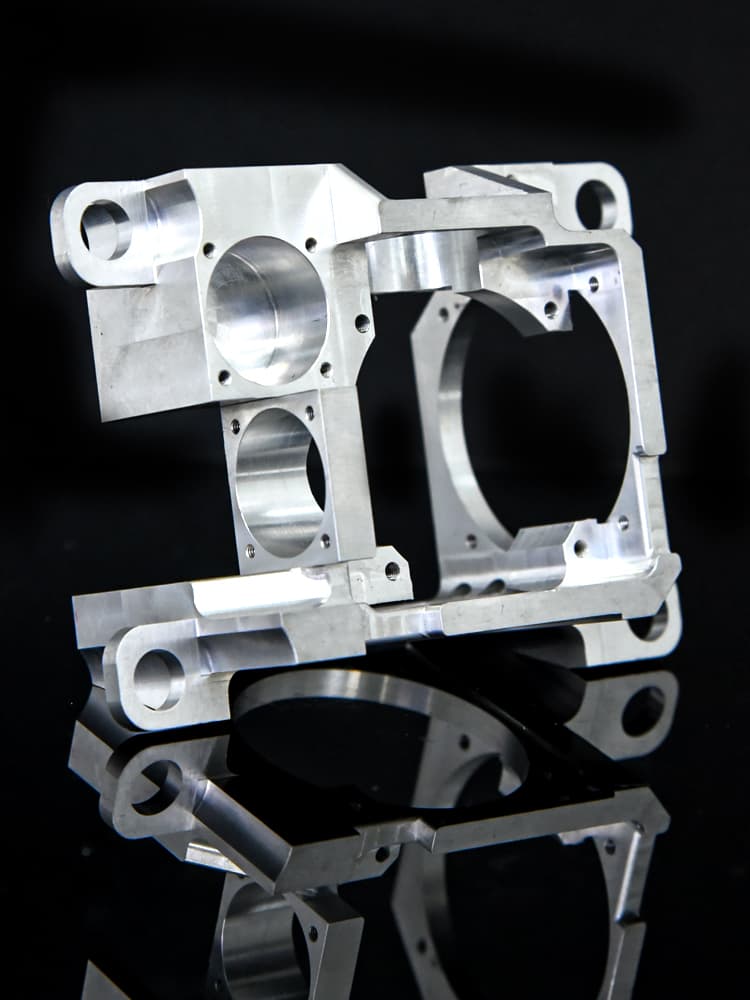

Aerospace Engine Components

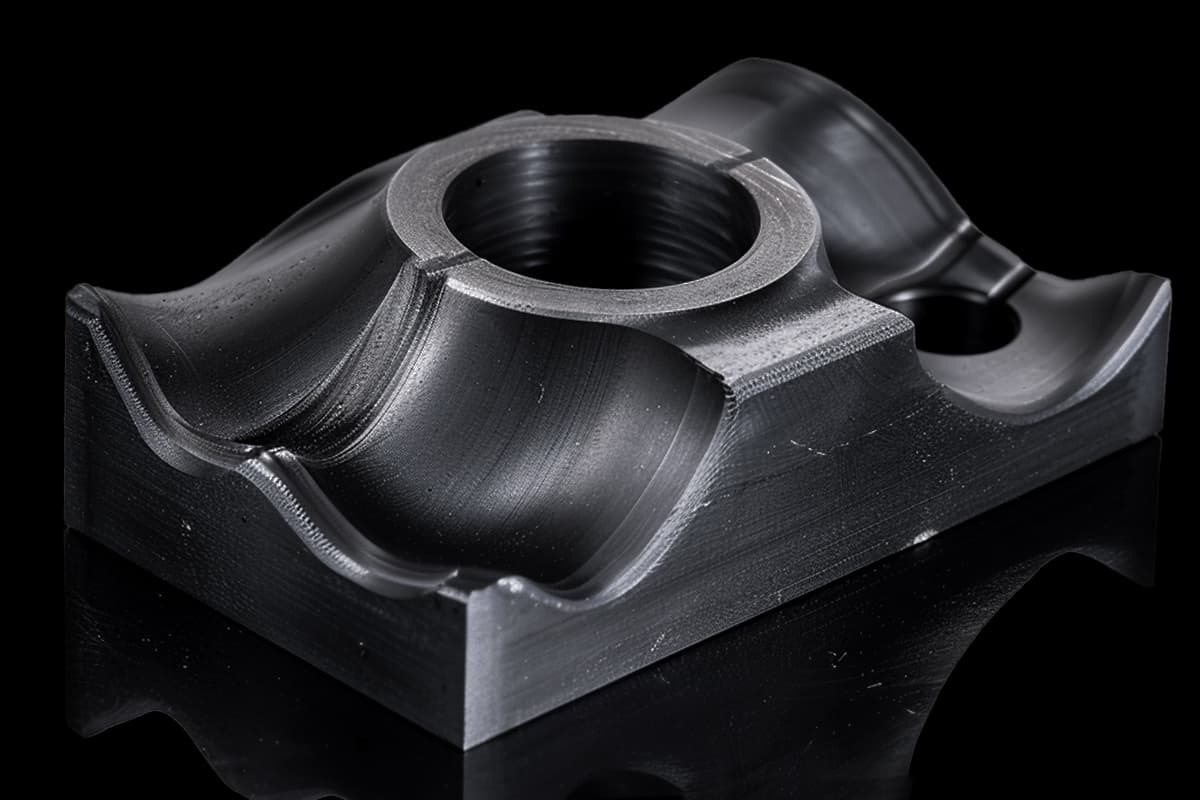

Engine Blocks and Cylinder Heads

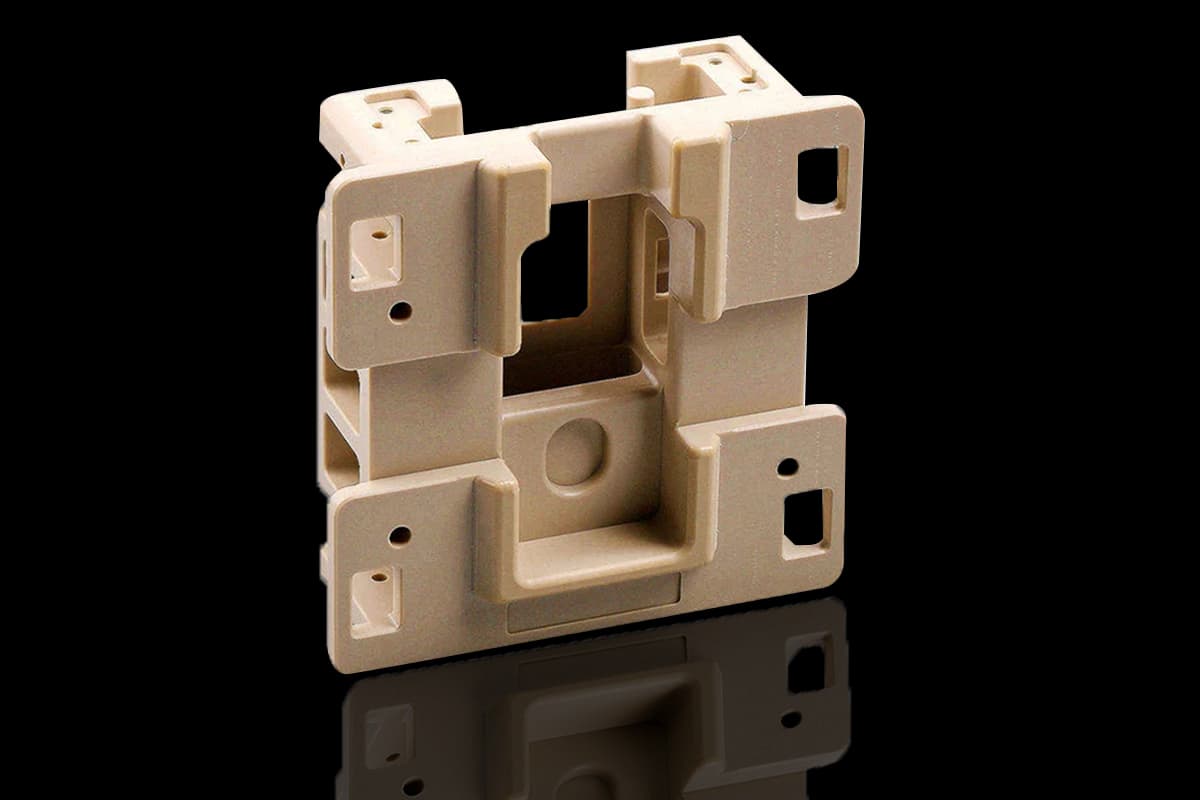

Precision Connectors

All uploads are secure and confidential.* Learn More

IOS 9001

IOS 14001

What is 5 Axis CNC Machining?

Traditional 3 Axis CNC machines are confined to linear X, Y, and Z axes,

5 Axis CNC Machining breaks these boundaries by introducing two additional axes: rotation on the X and Y axes, also known as A and B axes. This innovation empowers the cutting tool to access more workpiece areas from various angles, enhancing precision and versatility and ensuring both efficiency and accuracy.

| Axis | Working Manner |

|---|---|

| X-axis | Moves from left to right |

| Y-axis | Moves from front to back |

| Z--axis | Moves from top to bottom |

| A--axis | Rotates around the X-axis (tilts backward and forward) |

| B--axis | Rotates around the Y-axis (tilts from left to right) |

Maximizing Efficiency with 5-Axis Machining

5-axis machining easily handles parts with complex geometries, eliminating the need for multiple setups and significantly improving production efficiency.

Classification of 5-Axis Machining

| Machining Type | 5-Axis Machining with Two Rotational Axes | Simultaneous 5-Axis Machining | 3+2 Axis Machining (or 5-Sided Machining) | Positional 5-Axis Machining | Surface 5-Axis Machining |

|---|---|---|---|---|---|

| Working Method | Workpiece remains stationary while the cutting tool rotates to achieve different angles | Cutting tool and workpiece move simultaneously | Workpiece is positioned or supported for machining | Cutting tool moves to specific positions for machining | Cutting tool moves along the surface of the workpiece for cutting |

| Advantage | Handles complex geometric workpieces, allows for multi-angle cutting | Flexibility suitable for complex curves and 3D machining | Enables multi-surface machining, reducing re-clamping and setups | High-precision machining for fine details and surface finishing | Improves surface quality, reduces post-processing needs |

| Suitable Scenarios | Workpieces requiring multi-angle cutting | Complex curves and 3D machining | Workpieces requiring multi-surface machining | Workpieces requiring high precision and detailed machining | Workpieces requiring high surface quality and finish |

XIELIFENG 5-Axis Machining Equipment List

| Brand | Model | Travel (X/Y/Z) | Max Workpiece Size | Max. Load | Workpiece Type | Quantity |

|---|---|---|---|---|---|---|

| DMG | DMU 50 3rd Generation | 650 / 520 / 475 mm | Φ630 mm × 600 mm | 300 kg | Complex Surfaces, Molds, Precision Parts | 12 pcs |

| DMG | DMC 75 monoBLOCK | 750 / 650 / 560 mm | Φ630 mm × 500 mm | 600 kg | Medium-Sized Parts, Complex Parts | 10 pcs |

| Mazak | VARIAXIS i-300 AWC | 350 / 550 / 510 mm | Φ350 mm × 315 mm | 65 kg | Small Precision Parts, Complex Parts | 10 pcs |

| Mazak | VARIAXIS i-800T | 730 / 850 / 560 mm | Φ1000 mm × 375 mm | 1000 kg | Large-Sized Parts, Complex Parts | 10 pcs |

| Mazak | VARIAXIS i-600 | 510 / 910 / 510 mm | Φ700 mm × 450 mm | 500 kg | Medium-Sized Parts, Complex Parts | 6 pcs |

| Mazak | VARIAXIS j-500 | 350 / 550 / 510 mm | Φ500 mm × 350 mm | 200 kg | Complex Surfaces, Small Precision Parts | 4 pcs |

5 Axis CNC Machining Materials

Aluminum

Lightweight, moderately strong, corrosion-resistant, and easy to machine, with excellent thermal and electrical conductivity. Widely used in aerospace, automotive, and electronics.

Steel

High strength, wear resistance, hardness, and toughness, with good heat treatment adaptability. Widely used in heavy industry, construction, tools, and automotive parts.

Brass

Easy to machine, corrosion-resistant, with excellent electrical and thermal conductivity, and a bright appearance. Commonly used in valves, pipe fittings, electrical connectors, and decorative parts.

Copper

Exceptional electrical and thermal conductivity, corrosion-resistant, and easily formable. Widely used in electrical components, radiators, piping systems, and architectural decorations.

Titanium

High strength, lightweight, corrosion-resistant, heat-resistant, and biocompatible. Commonly used in aerospace, medical implants, high-end sports equipment, and chemical industries.

ABS

Good toughness, impact resistance, easy to process, lightweight, and cost-effective. Suitable for enclosures, structural parts, and consumer electronics.

POM (Polyacetal/Delrin)

High strength, low friction, wear-resistant, with excellent dimensional stability and chemical resistance. Commonly used for gears, bearings, sliders, and precision mechanical parts.

Nylon (PA)

High strength, excellent wear resistance, good chemical resistance, high toughness, and excellent fatigue resistance. Suitable for gears, pulleys, bushings, and transmission parts.

PEEK (Polyetheretherketone)

Exceptional high-temperature, chemical resistance, strength, rigidity, and wear resistance. Commonly used in aerospace, medical, semiconductor, and demanding applications.

5 Axis CNC Machining Parts Finishes

As machined

Color: Varies by material.

Finish Purpose: Creates decorative machining patterns, light surface scratches

Sand Blasting

Color: None (Textured Surface).

Finish Purpose: Uniform matte finish, enhances surface roughness.

Anodizing

Color: Various, e.g black, red.

Finish Purpose: Improve corrosion resistance, provide decorative effect.

Hardcoat anodizing

Color: Black, Gray.

Finish Purpose: Improve wear resistance and corrosion resistance.

Electroplating

Color: Various, e.g sliver, golden.

Finish Purpose: Improve appearance, increase corrosion resistance and decorativeness.

Polishing

Color: depends on material.

Finish Purpose: Improve the smoothness of the workpiece surface.

Brushing

Color: Silver, Matte finish.

Finish Purpose: Create decorative effect, enhance appearance.

Powder Coating

Color: Various, e.g white, black.

Finish Purpose: Provide protective coating, improve appearance.

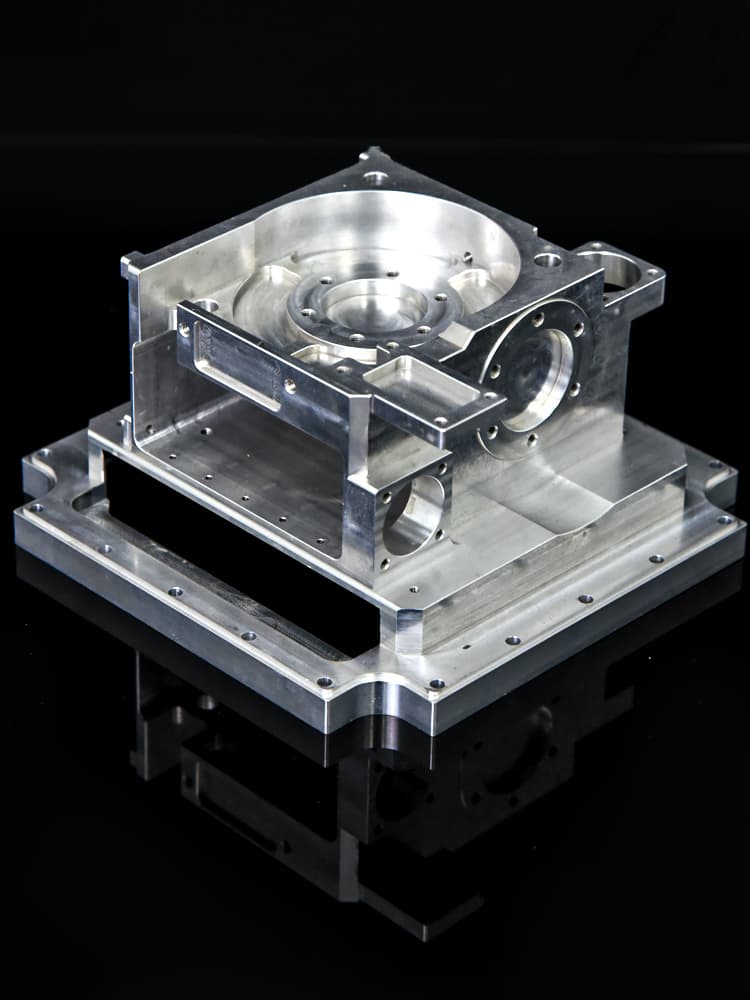

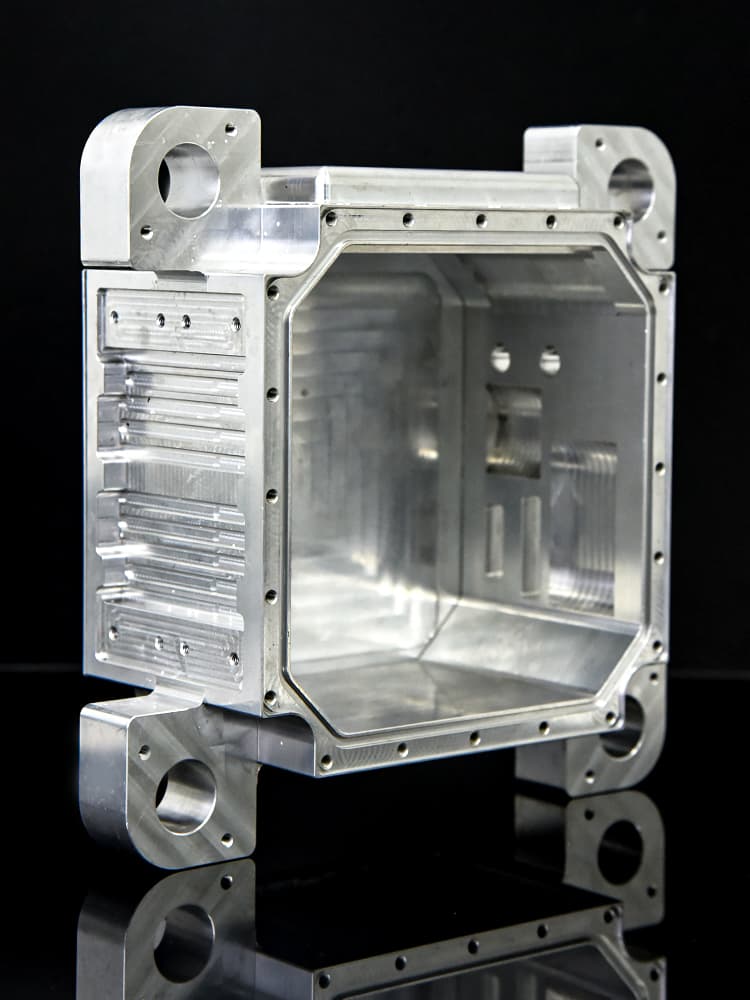

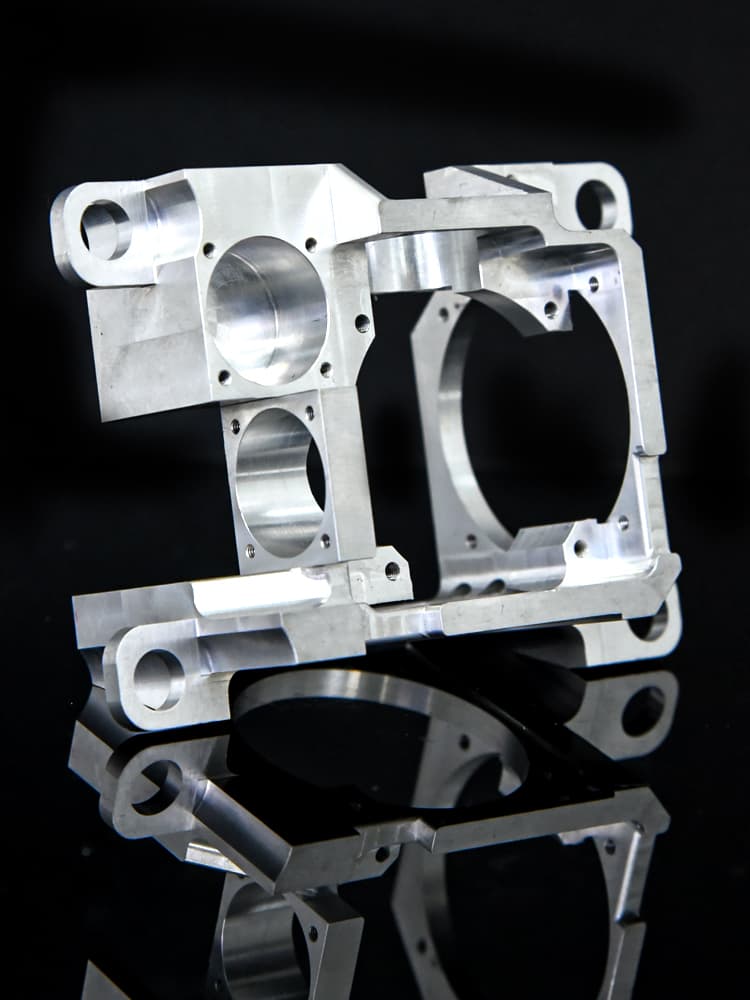

Xielifeng 5 Axis Complex Parts Case Studies

5 Axis CNC Machining Parts Tolerances & Standards ISO2768

In the machining parts industry, tolerances are crucial for ensuring that parts meet design requirements and are reliable in their applications. The ISO 2768 standard provides detailed guidelines for general tolerances, helping customers specify dimensional and geometric tolerances for parts when no specific tolerance requirements are given.

| Permissible deviations in mm for ranges in nominal lengths | Tolerance class designation (description) | ||||

|---|---|---|---|---|---|

| f (fine) | m (medium) | c (coarse) | v (very coarse) | ||

| 0.5 up to 3 | ±0.05 | ±0.1 | ±0.2 | - | |

| over 3 up to 6 | ±0.05 | ±0.1 | ±0.3 | ±0.5 | |

| over 6 up to 30 | ±0.1 | ±0.2 | ±0.5 | ±1.0 | |

| over 30 up to 120 | ±0.15 | ±0.3 | ±0.8 | ±1.5 | |

| over 120 up to 400 | ±0.2 | ±0.5 | ±1.2 | ±2.5 | |

| over 400 up to 1000 | ±0.3 | ±0.8 | ±2.0 | ±4.0 | |

| over 1000 up to 2000 | ±0.5 | ±1.2 | ±3.0 | ±6.0 | |

| over 2000 up to 4000 | - | ±2.0 | ±4.0 | ±8.0 | |

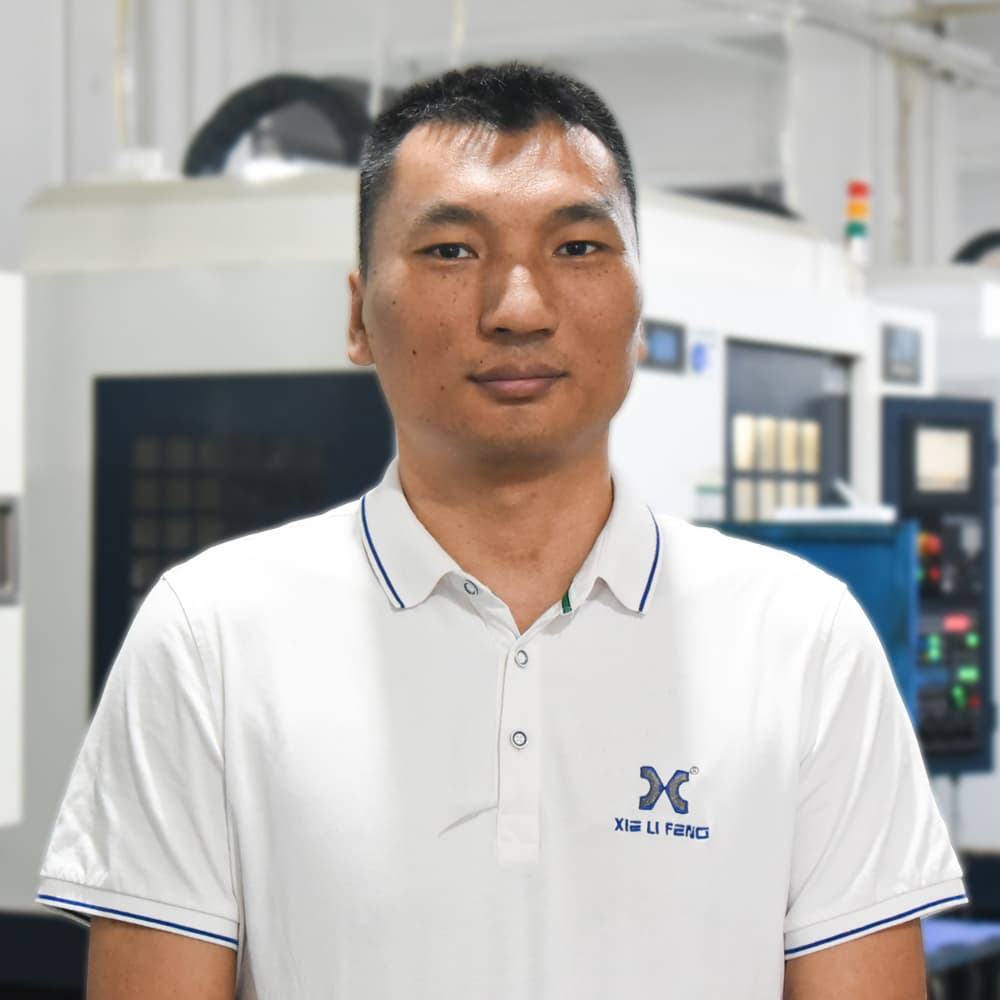

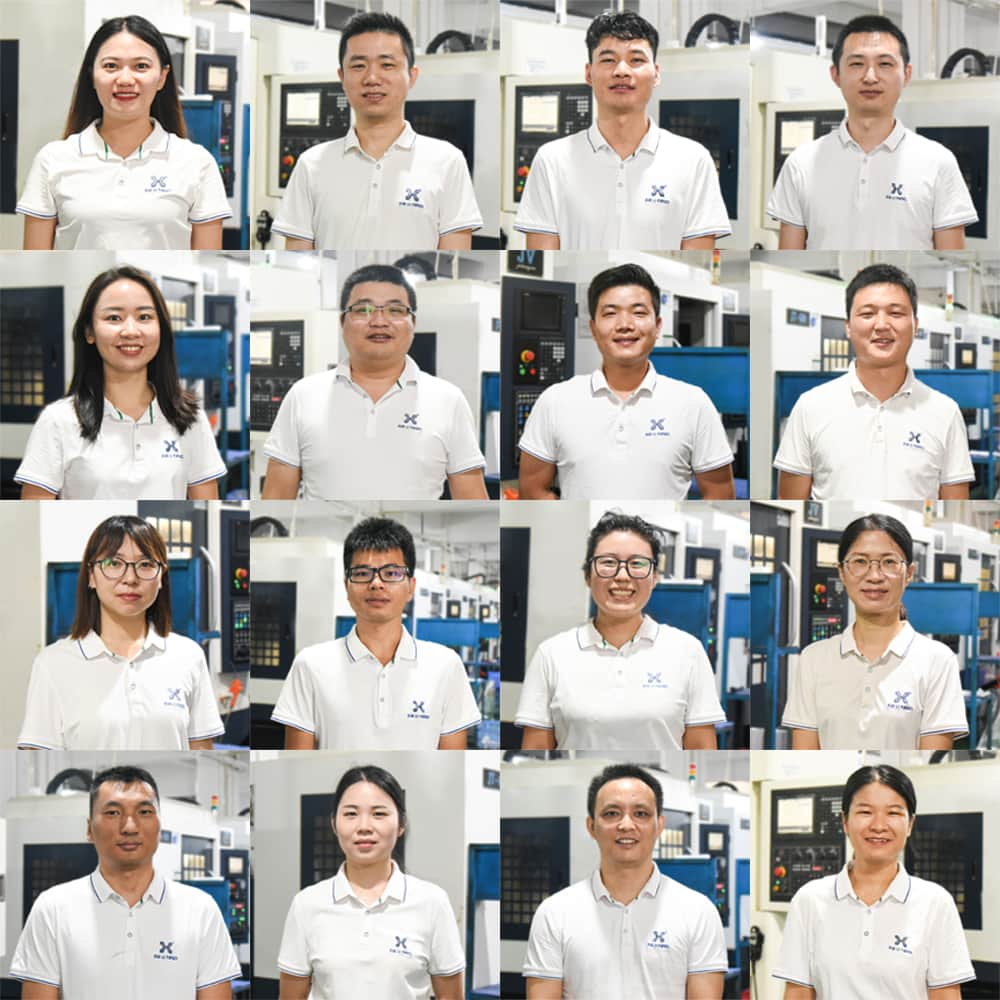

Professional Five-Axis Engineer Team

Brandon Hu

Experience: 7 years

Expertise: 5-Axis Programming

Specializing in high-precision program writing and path optimization, ensuring both part accuracy and surface quality while improving efficiency.

William Luo

Experience: 6 years

Expertise: 5-Axis Process Development

Focusing on crafting machining solutions for complex parts and optimizing processes to enhance production efficiency and part quality.

Joseph Zhang

Experience: 9 years

Expertise: 5-Axis Machine Operation

Excelling at ensuring efficient equipment performance, quick fault resolution, and continuous production flow.

Daisy Li

Experience: 10 years

Expertise: 5-Axis Quality Control

Specializing in setting strict inspection standards and using advanced equipment to ensure all parts meet the highest quality requirements.

Claire Huang

Experience: 15 years

Expertise: 5-Axis Efficiency Optimization

Focused on optimizing machining efficiency and productivity by refining parameters and processes, significantly boosting output while reducing costs.

Xielifeng equips itself with a diverse team of technical experts, forming a solid support system that covers programming, process development, maintenance, and quality control, ensuring efficient and high-quality project execution.

Specific 5-Axis Machined Parts Case Studies

Processing Requirements:

Turn-milling part, dimensional tolerance according to ISO2768-FH.

Processing Challenges:

Precision parts with complex structure, requiring milling slots at various angles and deep drilling of angled holes after turning.

Processing Solution:

We utilize 5-axis simultaneous machining, combined with precise turning and milling techniques, to meet the high-precision requirements for milling slots at various angles and deep drilling of angled holes. By carefully planning tool paths and controlling parameters strictly, we optimize the machining process and minimize errors. Customized fixtures and high-rigidity clamping solutions are used to ensure stable part positioning during machining, ensuring that each surface remains within tolerance for high-precision and efficient results.

Processing Requirements:

Milled parts requiring assembly with precise fit, dimensional tolerance according to ISO2768-F standard, flatness within 0.03mm, perpendicularity and positional tolerance within 0.02mm.

Processing Challenges:

The part has a complex structure, requiring high precision in fit and functionality. Even small errors can affect the assembly and performance.

Processing Solution:

We use 5-axis multi-directional machining to minimize clamping errors, ensuring high precision. By reducing clamping time, we enhance processing efficiency, ensuring both quality and delivery time.

Processing Requirements:

Turn-milled parts with dimensional tolerance according to ISO2768-F, concentricity, and positional tolerance within 0.02mm.

Processing Challenges:

The part is a precision component with a complex structure, requiring milling of slots and drilling from various angles after turning, ensuring accuracy in all areas.

Processing Solution:

We use 5-axis machining to minimize clamping errors, ensuring high precision. By reducing clamping time, we enhance overall efficiency, ensuring timely delivery and consistent quality.

Processing Requirements:

Curved thin plate with a special structure, dimensional tolerance according to ISO2768-FH.

Processing Challenges:

Each processing feature has vertical undercuts, requiring 5-axis simultaneous machining.

Clamping and positioning are difficult, as conventional vices and suction cups cannot secure the part effectively.

Processing Solution:

We use 5-axis simultaneous machining for precise processing and design a custom fixture system to securely clamp the part, ensuring accuracy and efficiency.

Processing Requirements:

Milled parts with dimensional tolerance according to ISO2768-F, flatness of 0.02, surface roughness Ra0.4 or less, with surfaces smooth enough to be aligned and attracted to each other.

Processing Challenges:

The part is a precision component with high surface finish requirements, large size, thin thickness, and prone to deformation during processing.

Processing Solution:

We use 5-axis machining to precisely control flatness and roughness, ensuring surface quality and dimensional stability. By optimizing the process and clamping methods, we minimize the risk of deformation.

Processing Requirements:

Turn-milling part, dimensional tolerance according to ISO2768-FH.

Processing Challenges:

Precision parts with complex structure, requiring milling slots at various angles and deep drilling of angled holes after turning.

Processing Solution:

We utilize 5-axis simultaneous machining, combined with precise turning and milling techniques, to meet the high-precision requirements for milling slots at various angles and deep drilling of angled holes. By carefully planning tool paths and controlling parameters strictly, we optimize the machining process and minimize errors. Customized fixtures and high-rigidity clamping solutions are used to ensure stable part positioning during machining, ensuring that each surface remains within tolerance for high-precision and efficient results.

Processing Requirements:

Milled parts requiring assembly with precise fit, dimensional tolerance according to ISO2768-F standard, flatness within 0.03mm, perpendicularity and positional tolerance within 0.02mm.

Processing Challenges:

The part has a complex structure, requiring high precision in fit and functionality. Even small errors can affect the assembly and performance.

Processing Solution:

We use 5-axis multi-directional machining to minimize clamping errors, ensuring high precision. By reducing clamping time, we enhance processing efficiency, ensuring both quality and delivery time.

Why Choose Xielifeng for 5 Axis CNC Machined Parts?

Fast Ddelivery:

Production starts within 24 hours, lead time reduced by 30%, 98% on-time delivery, small batch orders completed within 7 days, and year-round support ensures you stay ahead in the market.

Redesign Optimization:

By fine-tuning designs, we improve efficiency, reduce costs, and ensure quality and reliability. We offer material, process, and surface treatment recommendations to provide cost-effective solutions for our clients.

Project Management System

With 14 specialized teams, each led by a project manager and engineer, we provide dedicated support, real-time tracking, and one-stop service from design to delivery, ensuring high standards throughout.

Quality Assurance

Strictly adhering to ISO 9001 and ISO 14001 standards to ensure the stability and consistency of machined parts. Equipped with CMM and other tools to guarantee stable and precise quality.