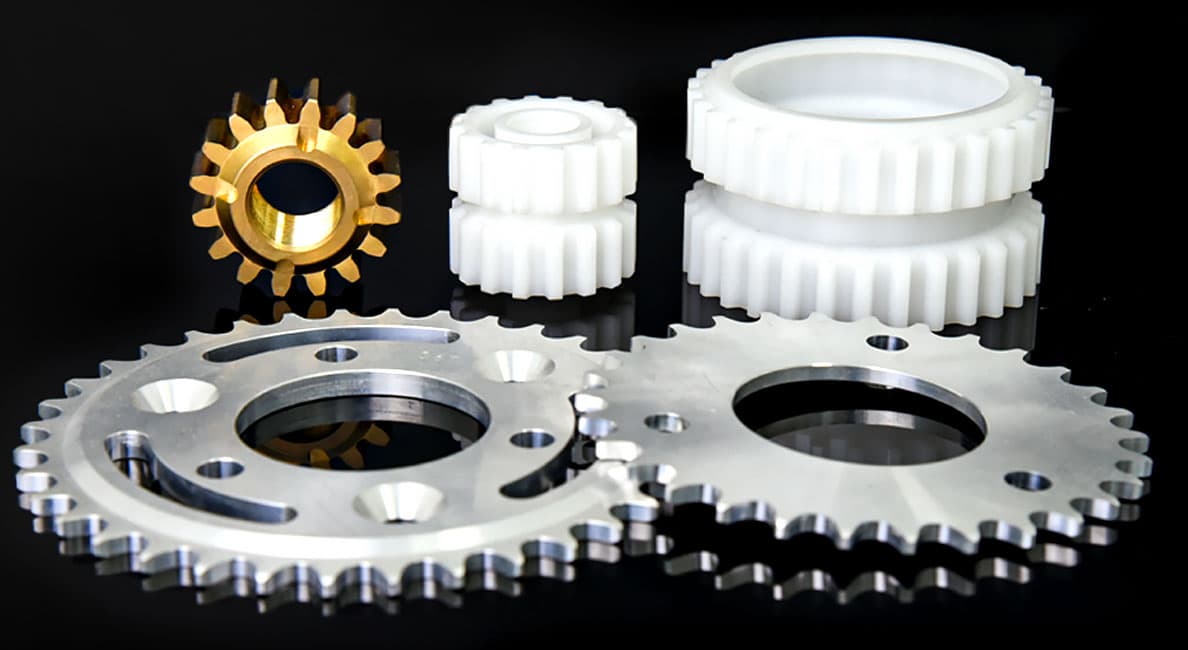

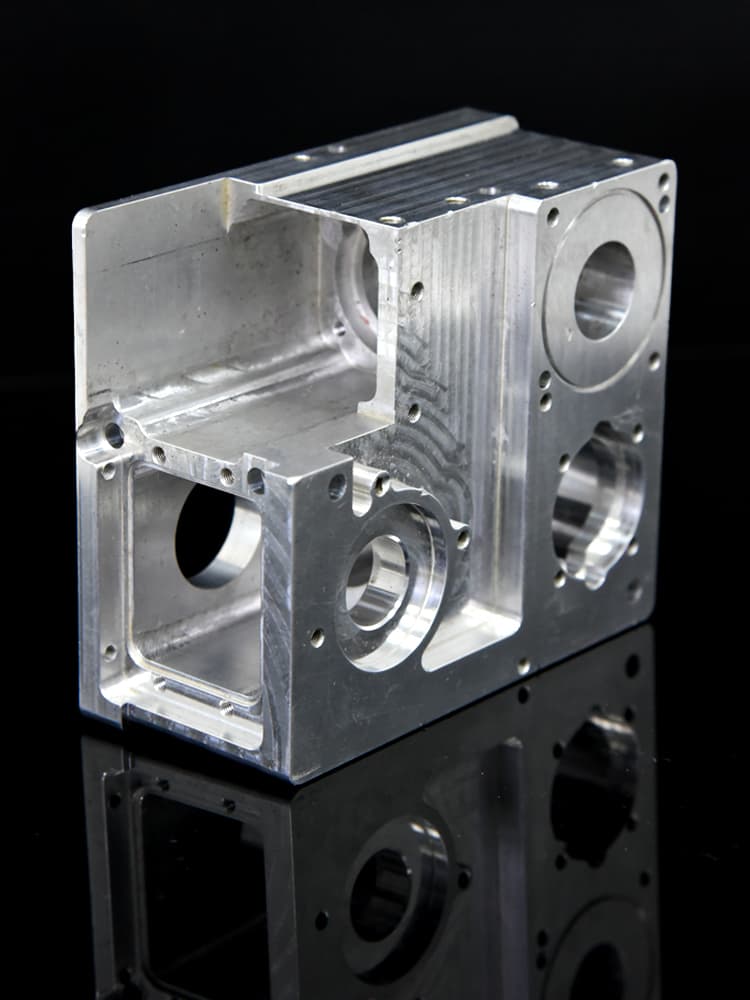

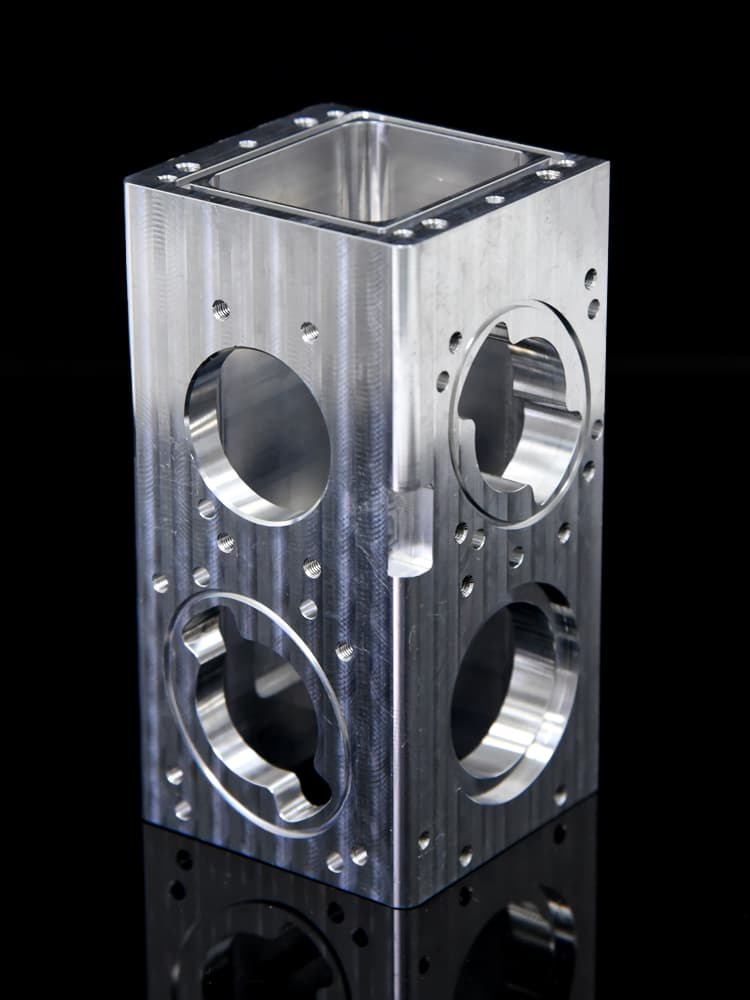

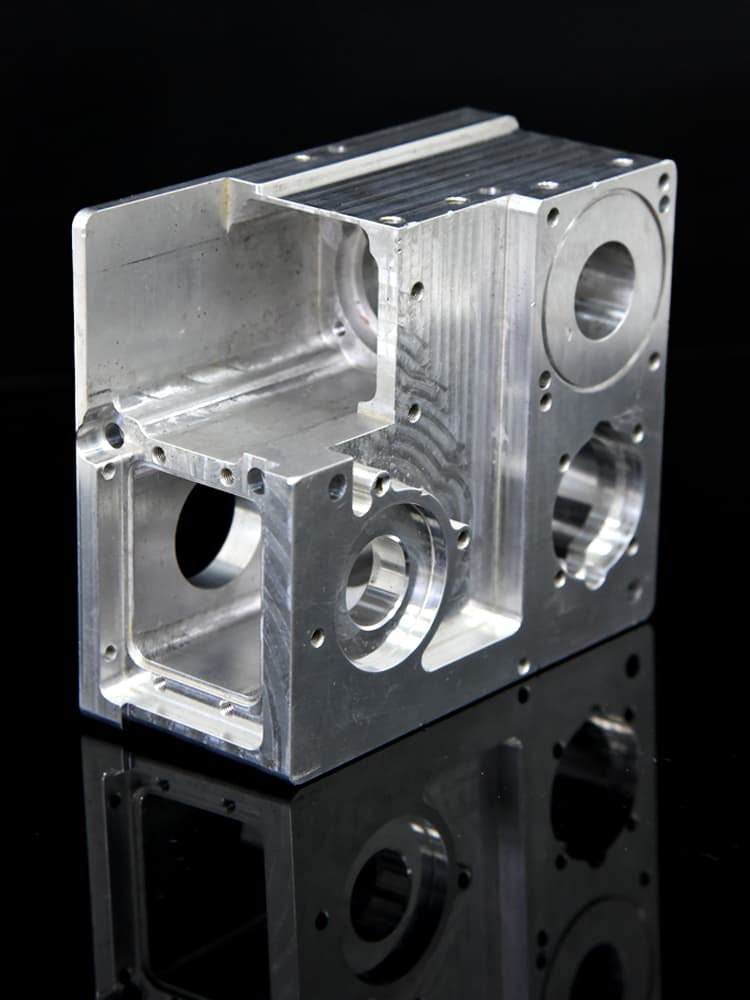

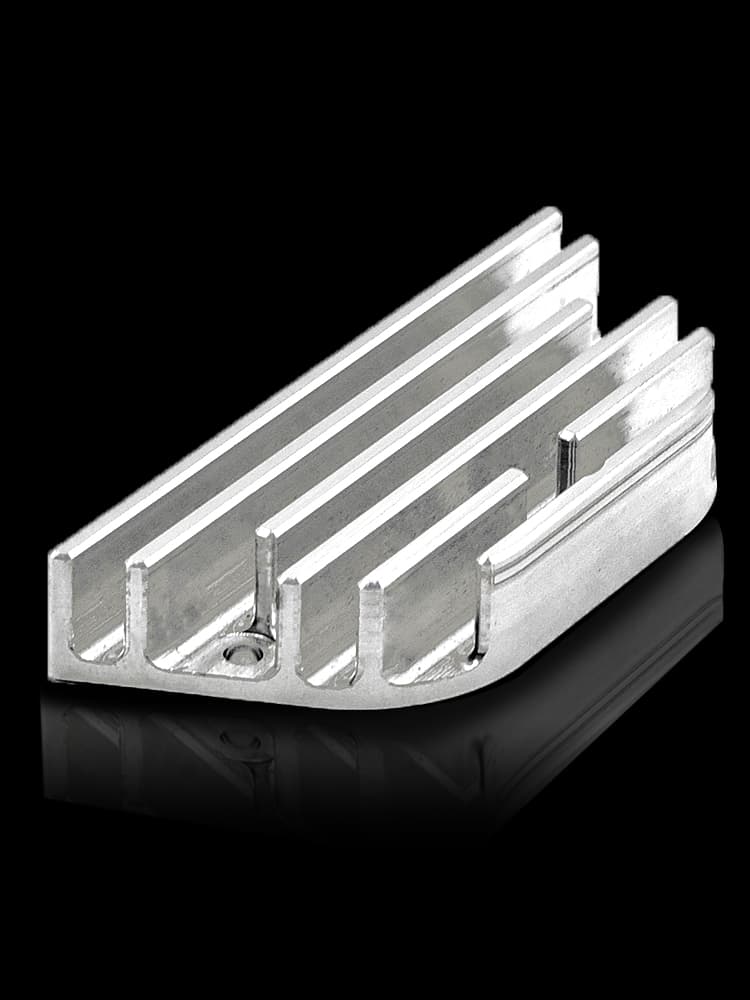

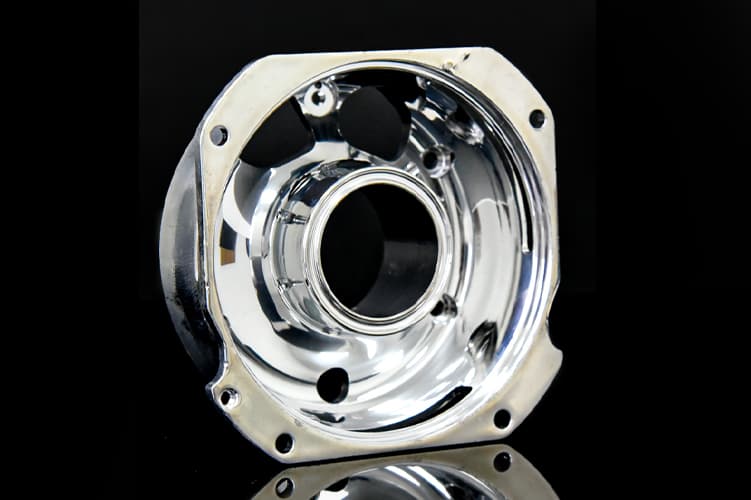

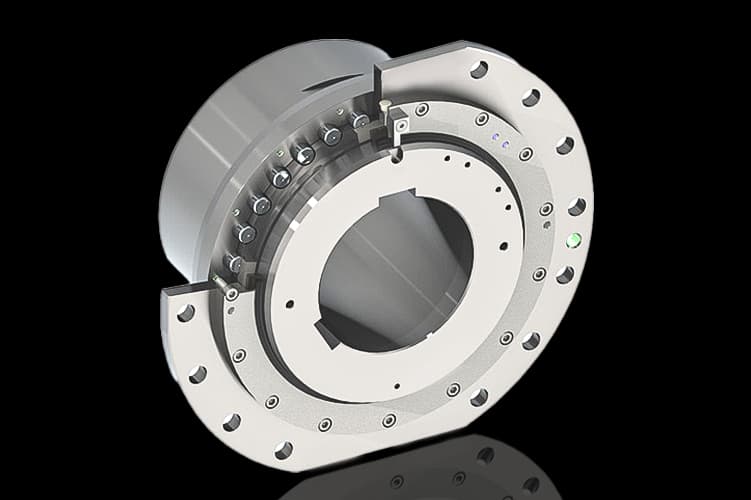

Achieving Stability and Strength in Every Part

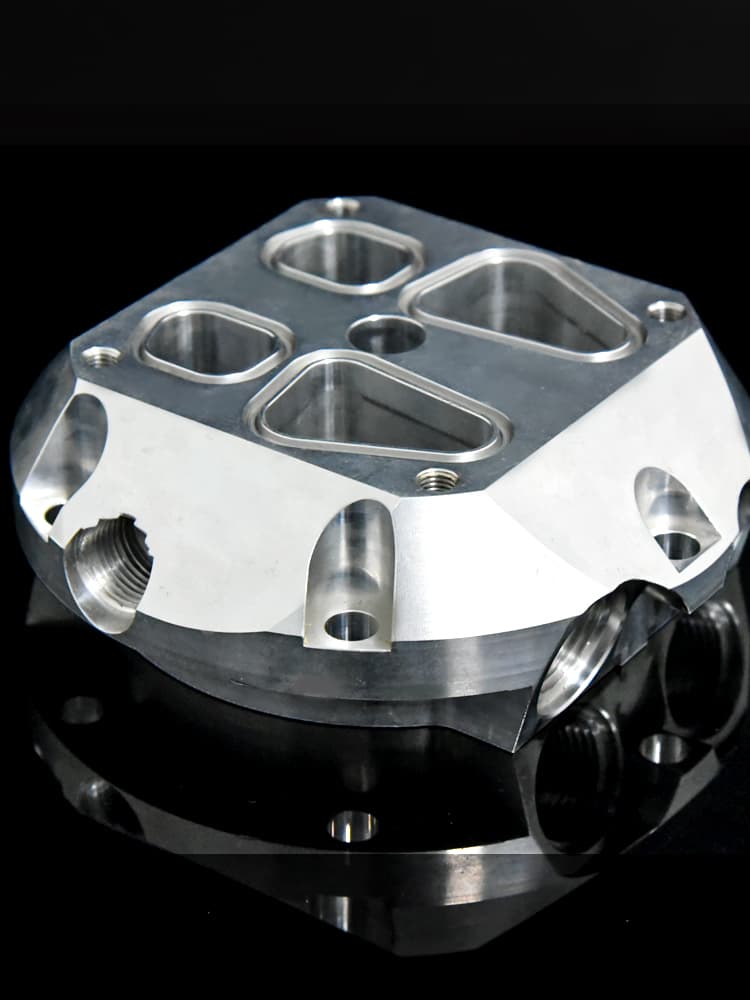

Specializing in pump bodies, bearing housings, and gear systems.

100,000+ parts annually, ensuring stability under high load and frequency.

All uploads are secure and confidential.* Learn More

IOS 9001

IOS 14001

About Our Capabilities

Rapid Response and Custom Production

Consistency in Mass Production

Cost Optimization and Enhanced Competitiveness

Rapid Response and Custom Production

Prototype manufacturing starts within 48 hours, and small-batch production is completed within 2 weeks. We deliver over 5,000 style customized parts annually, enabling clients to achieve design validation and market launch quickly.

Consistency in Mass Production

With strict quality control processes, we ensure 99.9% consistency in mass-produced parts, reducing assembly errors and enhancing overall equipment performance.

Cost Optimization and Enhanced Competitiveness

Through lean manufacturing and optimized machining processes, we help clients reduce production costs by an average of 15% while maintaining high quality and long part life.

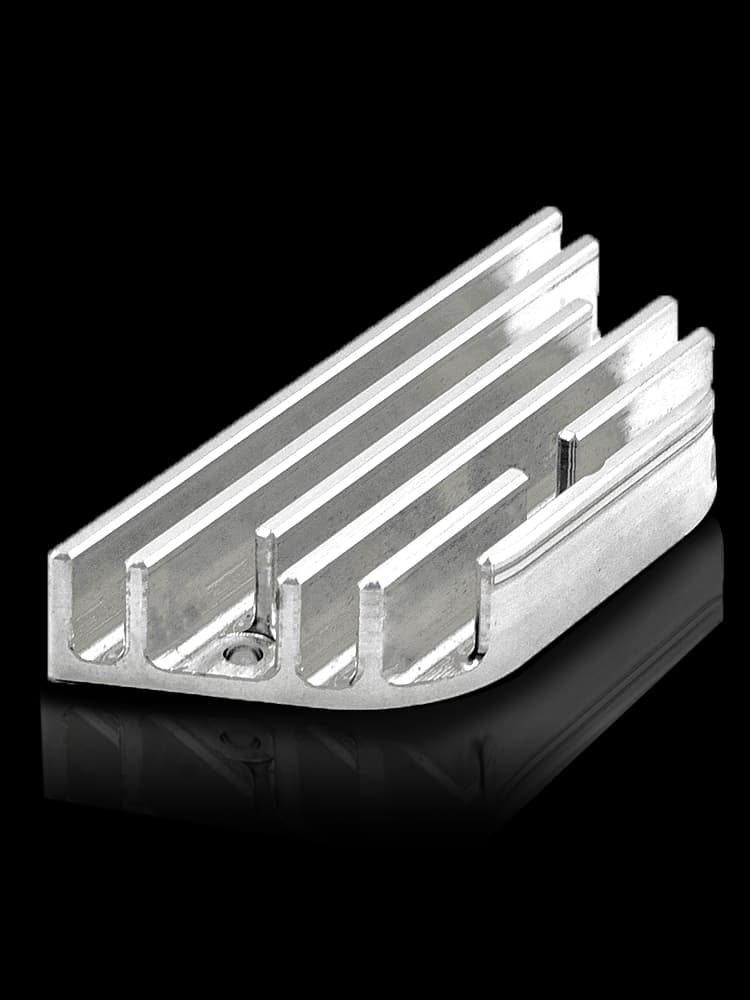

Application of parts for Industrial machinery

| Materials | Feature | Applicable Parts | Surface Treatment | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Aluminum | Lightweight, high strength, corrosion resistance | Exterior parts, connectors, supports, and frames | Anodizing, Powder Coating, Polishing | ||||||||||||

| Stainless Steel | Corrosion resistance, high strength | Shafts, valve components, frames, bearings | Polishing, Nickel Plating, Brushing, Nitriding | ||||||||||||

| Steel | High strength, wear resistance | Bearings, shafts, gears, transmission shafts | Chrome Plating, Heat Treatment | ||||||||||||

| Brass | Good electrical conductivity, corrosion resistance | Valve components, connectors | Nickel Plating, Polishing | ||||||||||||

| Copper | Good electrical conductivity, corrosion resistance | Tubing and fittings | Tin Plating, Nickel Plating, Polishing | ||||||||||||

| Titanium Alloy | Lightweight, high strength, corrosion resistance, high temperature resistance | Frames, shafts and joints, transmission shafts | Anodizing, Polishing | ||||||||||||

| ABS | Good strength and rigidity, easy to process | Housings, battery housings, connectors | No Surface Treatment | ||||||||||||

| POM | High rigidity, high strength, low friction coefficient | Insulating parts, electrical terminal housings | No Surface Treatment | ||||||||||||

| PC | High strength, impact resistance, transparency | Protective covers, exterior parts, connectors | No Surface Treatment | ||||||||||||

| PTFE | Low friction, high temperature resistance, chemical resistance | Seals, gaskets, sliding bearings | No Surface Treatment | ||||||||||||

| PP | Chemical resistance, fatigue resistance, good elasticity | Tubing, valves, liners | No Surface Treatment | ||||||||||||

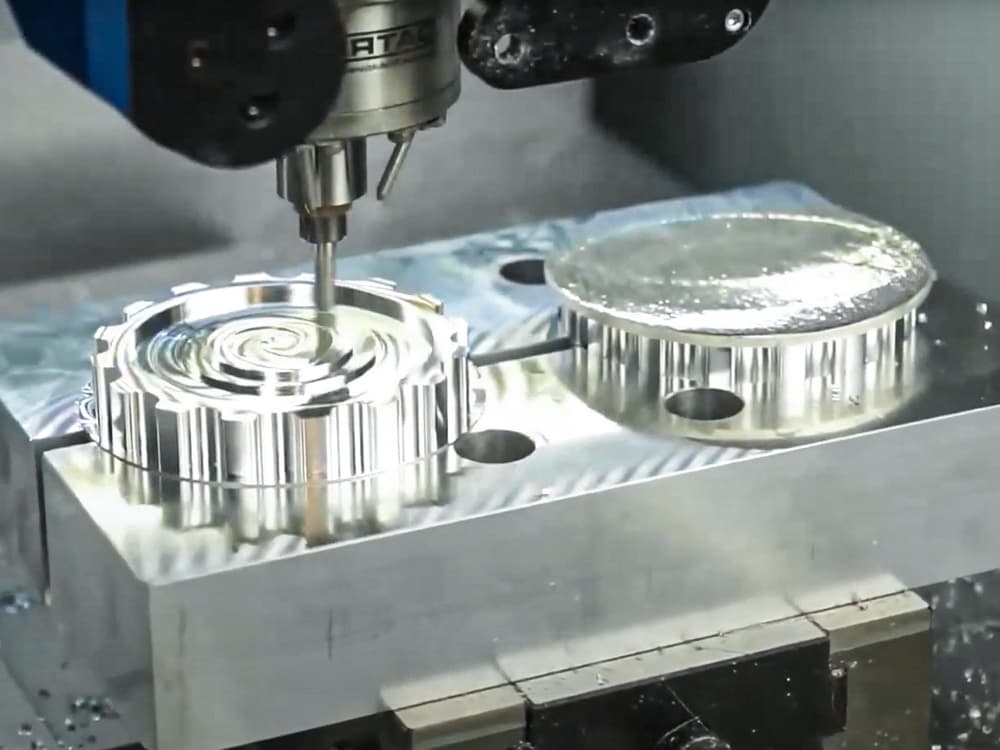

CNC Industrial & Mechanical Parts Case Study

Our Partners

and mechanical companies annually, delivering more than 2,000,000 parts each year

with an on-time delivery rate of over 98%, helping our clients stay competitive in demanding market environments.

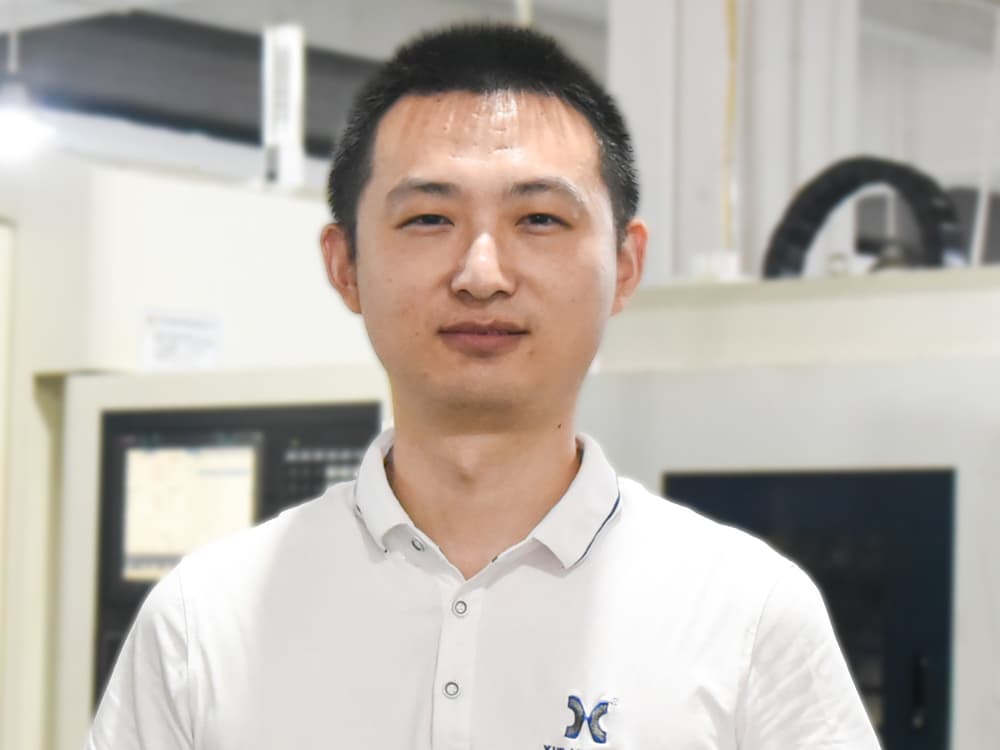

Industrial & Mechanical Industry Engineer Joseph from Xielifeng has something to say

Senior Engineer Joseph, 9 years of experience in machining high-strength and durable components for industrial machinery. Specialized in producing parts such as gears, shafts, and housings for heavy-duty applications, ensuring long-term reliability under harsh operating conditions.

What are the biggest challenges when machining components for heavy-duty industrial machinery?

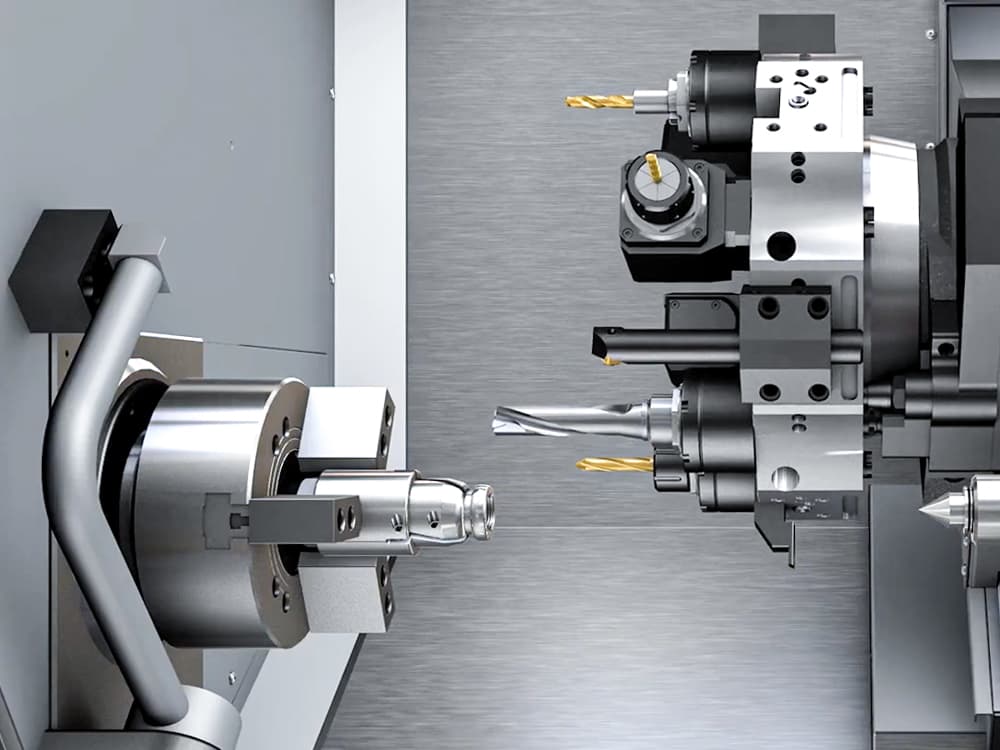

The main challenge is balancing strength and precision. Industrial machinery components are often subject to high stress and wear, so we use high-strength materials like alloy steels and titanium. At the same time, tight tolerances must be maintained to ensure proper function. We use specialized CNC machines capable of handling large parts without compromising accuracy.

How do you ensure long-term durability for components used in industrial machinery?

To ensure durability, we select wear-resistant materials such as hardened steels and apply surface treatments like heat treating or nitriding to improve the hardness and wear resistance of components. We also conduct fatigue testing to verify the parts can endure long-term mechanical stress. These processes help extend the lifespan of the components in tough industrial environments.

How do you handle the machining of oversized industrial components with complex geometries?

For oversized components, we use large-capacity CNC machines capable of machining parts with both size and precision. We also utilize custom fixtures and tool paths to ensure accurate machining of complex geometries. During production, in-process inspections are carried out to monitor accuracy and make adjustments as needed to ensure precision at every stage.

How do you ensure smooth operation of mechanical parts in continuous-use environments?

We ensure smooth operation by machining components with tight concentricity and alignment tolerances. For rotating parts, such as shafts, we use dynamic balancing equipment to detect and eliminate imbalances. In addition, we recommend using self-lubricating materials and designing integrated lubrication channels to reduce friction and wear over extended periods of use.

How do you meet the requirements for precision alignment during the installation of industrial components?

We provide precision machining services to ensure that components meet tight dimensional tolerances, minimizing alignment issues during installation. Our engineers also create custom alignment fixtures to assist in the assembly process, ensuring proper fit. Furthermore, we offer on-site support for critical installations, helping clients achieve optimal alignment and functionality.

How do you ensure cost efficiency in the production of industrial parts without compromising quality?

We ensure cost efficiency through lean manufacturing practices, optimizing material usage and reducing waste. By leveraging automated CNC machining, we can run high-volume production while maintaining precision and minimizing human error. Additionally, we work closely with clients during the design phase to identify cost-saving opportunities without sacrificing functionality or durability.

How Xielifeng Works

From quotation to delivery, we provide efficient, high-quality services, making manufacturing more convenient.

01

Upload drawing

CAD files: 2D: DXF | DWG | PDF 3D: STP | STEP |IGS | IGES| X_T | SLDPRT

02

DFM Evaluation & Quote

- Drawing review

- Process analysis

- Material inspection

- Feasibility proposal

- Cost estimation

03

Order Confirmtion & Production

- Sample processing

- Sample quality inspection

- Customer confirmation

- Mass production plan

04

Quality Inspection & Delivery

- Raw material inspection

- First piece inspection

- Process inspection

- Final inspection

- Inspection report