Custom Precision Firefighting Components Engineered for Reliability in Critical Moments

Prototype to Production in 1-3 Days

99.9% Quality Pass Rate in Critical Applications

Fast Prototyping with 98% On-Time Delivery

All uploads are secure and confidential.* Learn More

IOS 9001

IOS 14001

About Our Capabilities

High-Pressure & Fatigue-Resistant Parts Safety

Precision Machining Ensures Reliable Performance

Rapid Response and Quick Custom Production

High-Pressure & Fatigue-Resistant Parts Safety

Machining impact-resistant components with 200,000 cycle tests showing no leakage.

Material fatigue resistance improved by 40%, ensuring greater stability.

upporting 50+ projects with a 99.8% zero-failure rate for parts.

Precision Machining Ensures Reliable Performance

Utilizing CNC machining with ±0.005mm tolerance.

Annually producing 100,000+ precision parts for firefighting equipment with a 99.9% pass rate.

Ensuring fault-free operation during critical moments.

Rapid Response and Quick Custom Production

Prototype manufacturing starts within 48 hours, small-batch production was completed in 2 weeks.

Serving 50+ firefighting equipment manufacturers, delivering 5,000+ parts annually.

On-time delivery rate exceeds 98%.

Application of Parts for Firefighting Industry

| Materials | Feature | Application Parts | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Aluminum | Lightweight, high strength, good corrosion resistance | Pump bodies, pump covers, connectors, supports, exterior parts | |||||||||||||

| Stainless Steel | High strength, corrosion, temperature resistance | Fire extinguisher bodies, valves, connectors, sealing parts | |||||||||||||

| Carbon Steel | High strength, wear resistance, low cost, weldable | Vehicle parts, supports, braking system components, chassis parts | |||||||||||||

| Copper & Copper Alloys | Good conductivity, corrosion, wear resistance | Connectors, valves, pipe fittings, transmission components | |||||||||||||

| Brass | Good conductivity, corrosion resistance, easy machining | Connectors, spray nozzles, electrical parts, adjustment valves | |||||||||||||

| Titanium Alloy | Lightweight, high strength, corrosion, heat resistance | Structural components, spray nozzles, connectors, fasteners | |||||||||||||

| PA | Wear resistance, heat resistance, chemical resistance | Valve bodies, gears, sliding parts, fasteners | |||||||||||||

| PET | High strength, chemical resistance, insulation | Pump bodies, filter components, insulating parts | |||||||||||||

| POM | High strength, low friction, chemical resistance | Valves, gears, connectors, fasteners | |||||||||||||

| PP | Lightweight, chemical resistance, good insulation | Pipe fittings, sealing parts, valve components | |||||||||||||

Surface Finishing for CNC Firefighting Parts

| Surface Treatment | Feature | Aupplication Parts | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Zinc Plating | Provides good corrosion resistance, cost-effective | Fire extinguisher bodies, pipe fittings, supports | ||||||||||||

| Anodizing | Enhances aluminum corrosion and hardness, dyeable | Aluminum exterior parts, pump bodies, nozzles | ||||||||||||

| Powder Coating | Provides corrosion and wear resistance, colors option | Exterior parts, supports, pipe fittings, handles | ||||||||||||

| Electrophoretic | Uniform coating, corrosion resistance good appearance | Valve covers, connectors, supports, sealing parts | ||||||||||||

| Phosphating | Increases corrosion resistance, improves adhesion | Steel exterior parts, supports, fasteners, screws, nuts | ||||||||||||

| PTFE Coating | Provides excellent corrosion resistance and low friction | Valve parts, sealing parts, connectors, pipe fittings | ||||||||||||

| Heat Treatment | Improves metal hardness and wear resistance | Gears, axles, fasteners, structural components | ||||||||||||

Custom FireProof Parts Case Study

About the Parts We've Made

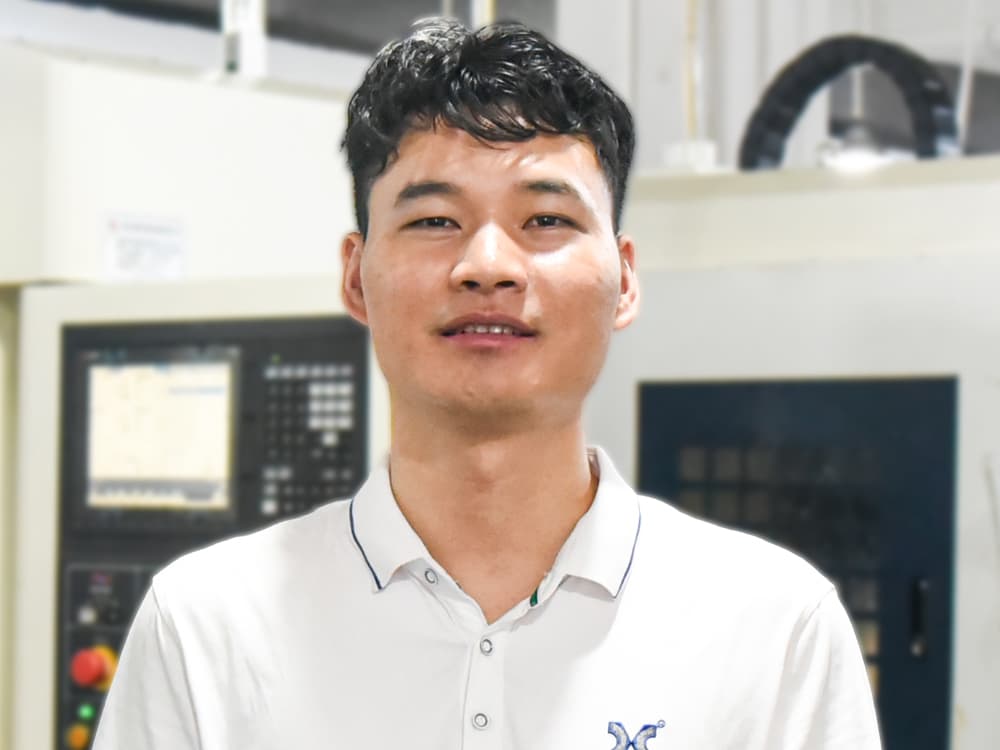

Firefighting Equipment Industry Engineer Benjamin from Xielifeng Has Something to Say

Senior Engineer Benjamin, 10 years of experience in machining high-strength, precision components for firefighting equipment. Specializes in critical components such as valves, fittings, and nozzles that require high durability and reliability to function under extreme conditions.

What materials are ideal for firefighting components to withstand high temperatures and corrosion?

For high-temperature and corrosive environments, we recommend stainless steel and brass for their excellent corrosion resistance. Aluminum alloys are also used for lightweight components, particularly in portable equipment. In addition, bronze fittings are preferred in marine firefighting applications due to their high resistance to seawater corrosion.

How do you ensure the precision of critical firefighting components like valves and nozzles?

We use 5-axis CNC machines to machine these critical parts with tight tolerances, ensuring optimal flow control and sealing. Post-machining inspections with coordinate measuring machines (CMMs) validate dimensions, and we perform leakage and flow tests to ensure that the components function reliably in the field.

How do you address the challenge of machining components that require both strength and precision?

We use high-strength materials like stainless steel and employ specialized cutting tools to maintain precision without compromising material integrity. During machining, we carefully control cutting parameters to minimize stress on the material, and we use heat treatment processes where necessary to enhance the mechanical properties of the final components.

How do you ensure that firefighting components meet industry safety standards?

We follow NFPA (National Fire Protection Association) and other international standards throughout production. Every part undergoes pressure and stress testing to ensure it can withstand extreme conditions. We also conduct material traceability checks to guarantee that all components meet the required safety and performance specifications.

How do you prevent corrosion in firefighting components exposed to harsh environments?

We apply anodizing, powder coating, and electroplating processes to protect metal surfaces from corrosion. For components used in marine or chemical environments, we use PTFE coatings to provide additional resistance. Our quality control team conducts salt spray testing to validate the corrosion resistance of these treatments.

How do you ensure traceability and accountability in firefighting component production?

We maintain a comprehensive documentation system that tracks each component from raw material procurement to final delivery. Every part is assigned a unique serial number, allowing us to trace its production history, material sources, and testing results. This ensures full accountability and simplifies post-production audits or recalls if necessary.

How Xielifeng Works

From quotation to delivery, we provide efficient, high-quality services, making manufacturing more convenient.

01

Upload drawing

CAD files: 2D: DXF | DWG | PDF 3D: STP | STEP |IGS | IGES| X_T | SLDPRT

02

DFM Evaluation & Quote

- Drawing review

- Process analysis

- Material inspection

- Feasibility proposal

- Cost estimation

03

Order Confirmtion & Production

- Sample processing

- Sample quality inspection

- Customer confirmation

- Mass production plan

04

Quality Inspection & Delivery

- Raw material inspection

- First piece inspection

- Process inspection

- Final inspection

- Inspection report