Powering Automotive Progress with Custom Auto Parts

Serving 10+ automotive manufacturers

Machined 1,000+ complex automotive parts

30% faster than the industry average

All uploads are secure and confidential.* Learn More

About Our Capabilities

Strict Quality Control and Standard Compliance

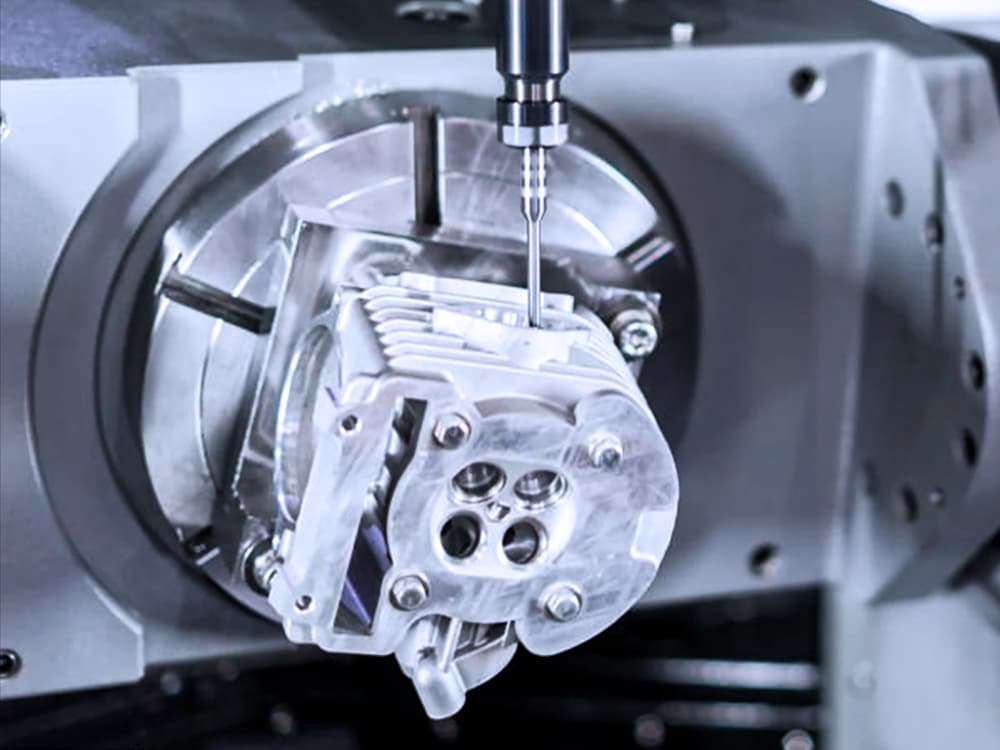

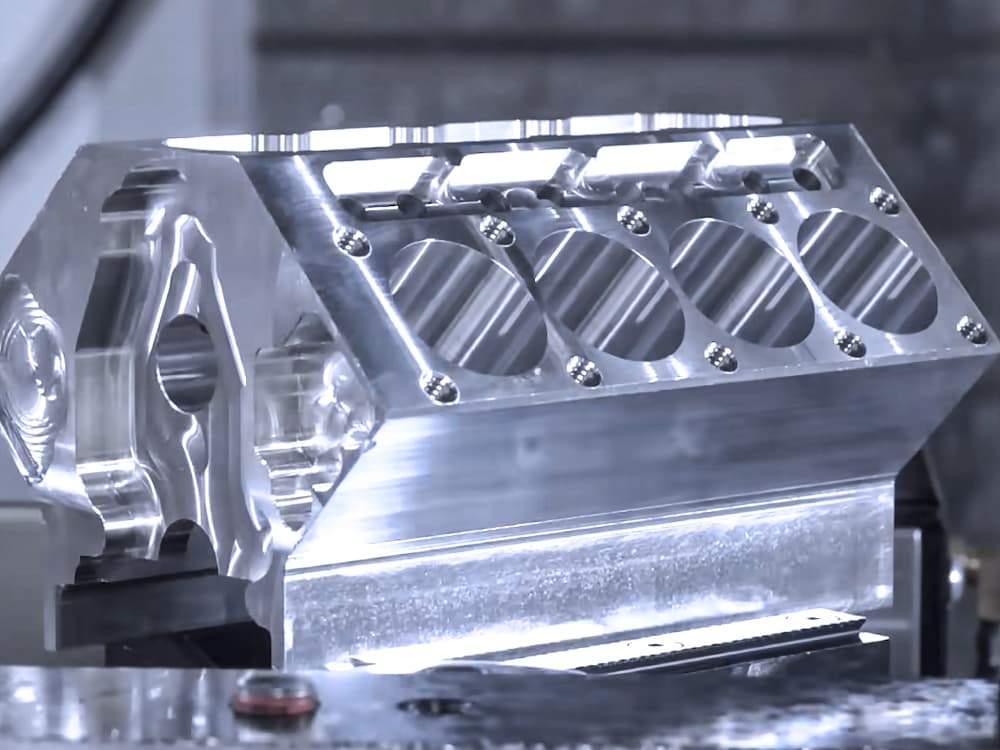

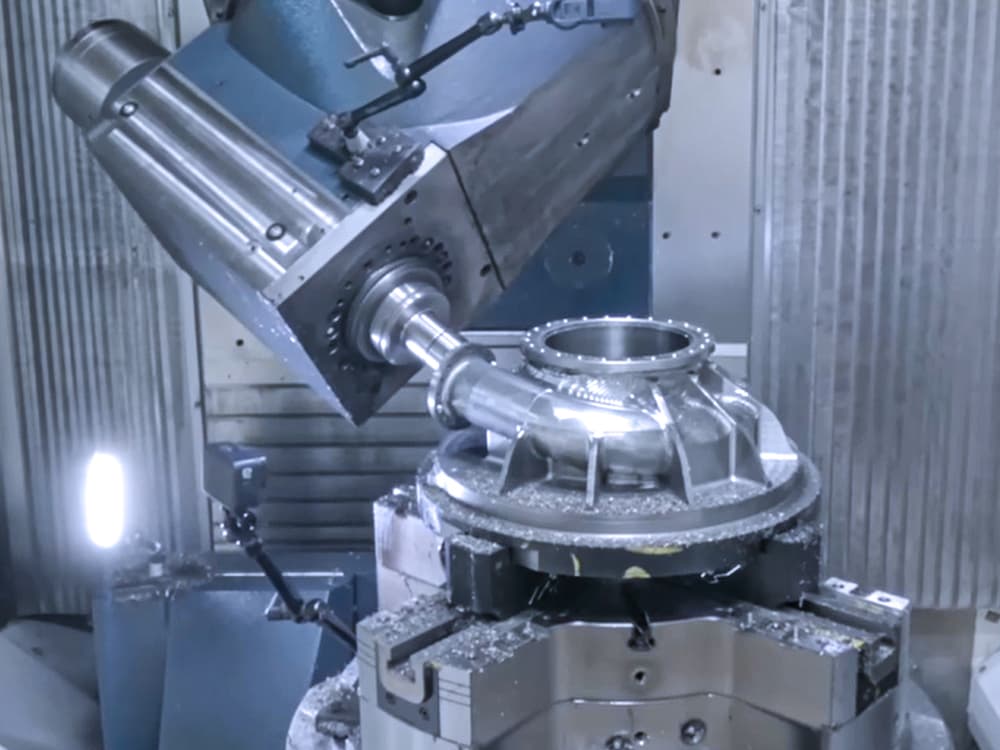

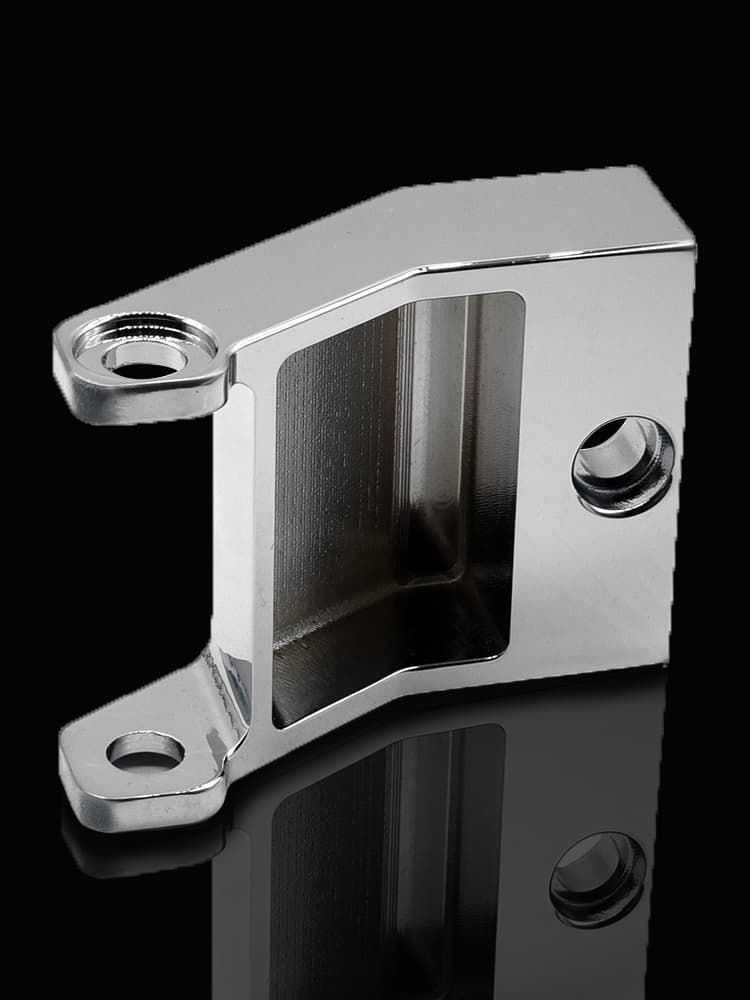

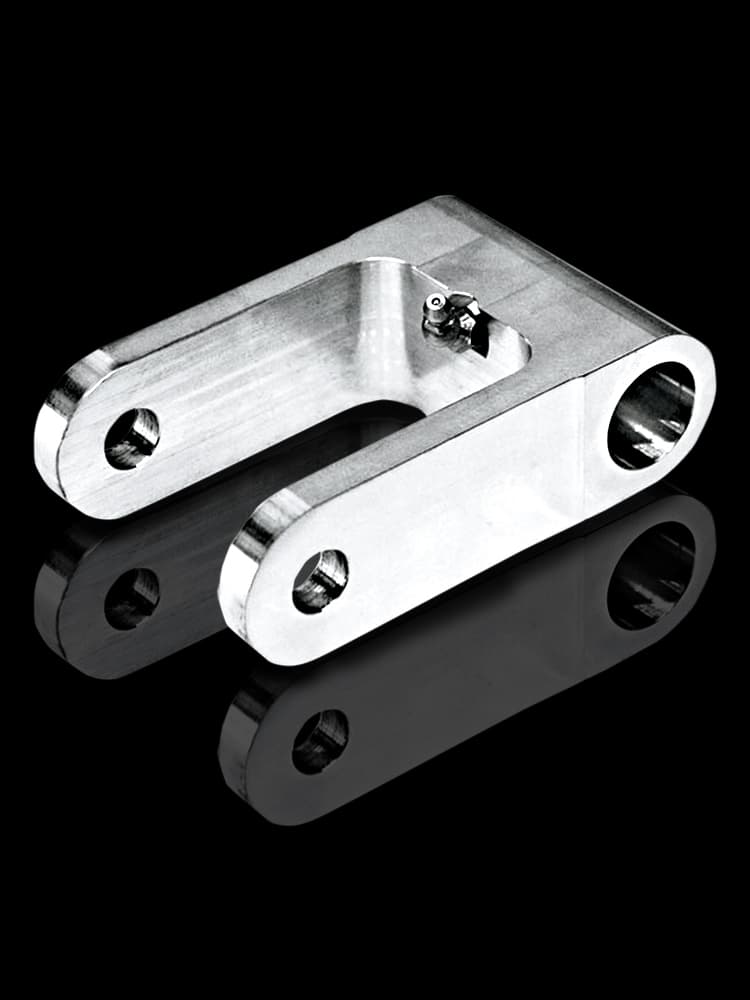

High Precision and Complex Shape Machining Capability

Custom Machining

and Fast Delivery

Strict Quality Control and Industry Standard Compliance

ISO/TS 16949 certified with 24 years of experience in automotive parts machining.

Serving 20+ automotive manufacturers with a return rate of less than 0.09%.

Full-process data monitoring and 100% dimensional inspection to ensure consistency.

High Precision and Complex Shape Machining Capability

5-axis machining equipment with precision up to ±0.005mm.

Successfully machined over 1,000 types of complex automotive parts.

High-precision machining reduces assembly time and enhances overall vehicle fitment.

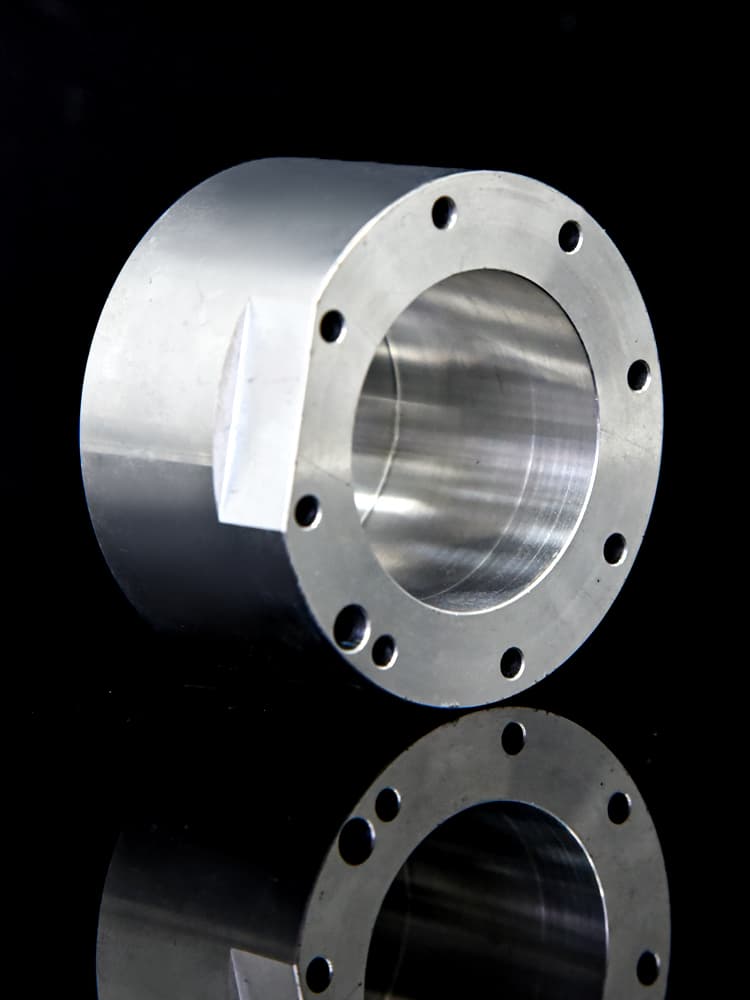

Custom Machining and Fast Delivery

Equipped with 200 machines, with an annual production exceeding 5 million pieces.

50 tons of stocked materials, enabling production to start within 48 hours.

Average delivery time for custom parts is 10 days, 30% faster than the industry average.

Application of Custom Automotive Parts

Engine and Related Parts

Cylinder Block

Cylinder Head

Crankshaft

Camshaft

Connecting Rod

Piston

Drivetrain Components

Transmission Housing

Gears

Bearings

Clutch Components

Drive Shaft

Braking System Components

Brake Disc

Brake Drum

Brake Caliper

Brake Pump

ABS Components

Chassis and Suspension System

Axle

Components

Steering Knuckle

Control Arm

Shock Absorber Bracket

Body Structure Components

Door Handle

Dashboard Bracket

Bumper Bracket

Interior & Exterior Trim

Components

Seat Frame Components

Door Panel Frame

Trim Strips

Electrical & Electronic System

Components

Battery Housing

Connectors

Sensor Housing

Fuel System and Exhaust System

Components

Fuel Injector Housing

Fuel Pump Components

Exhaust Pipe

Muffler

Materials for CNC automobile parts

| Name | Feature | Application Parts | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Aluminum | Good strength, lightweight, corrosion resistance, good thermal conductivity | Body structure, engine components, wheels, drivetrain components | |||||||||||||

| Stainless Steel | Good corrosion resistance, high strength, good machinability | Exhaust pipes, screws, brake discs, door handles, trim | |||||||||||||

| Steel | High strength, good formability, good machinability | Body structure, engine components, chassis systems, drivetrain systems | |||||||||||||

| Titanium | High strength, excellent corrosion resistance, low density, good high-temperature stability | Engine components, exhaust systems, starters, drivetrain systems | |||||||||||||

| PC (Polycarbonate) | High impact resistance, transparency, good chemical resistance | Buttons, headlights, rearview mirrors | |||||||||||||

| PP (Polypropylene) | Lightweight, good chemical resistance, good impact resistance | Bumpers, door panels, dashboards, air deflectors | |||||||||||||

| PE (Polyethylene) | Good wear resistance, good heat resistance, low cost | Body structure, interior components, protective covers | |||||||||||||

| PA (Nylon) | High strength, good wear resistance, good chemical resistance | Air filter housings, oil tanks, brake components, brake fluid reservoirs | |||||||||||||

CNC Automotive Parts Post-Processing Capabilities

| Surface Treatment | Characteristics | Automotive Parts | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Electroplating | Improves corrosion resistance and wear resistance of parts | Hardware parts, screws, body trim, exhaust pipes | ||||||||||||

| Anodizing | Improves hardness and corrosion resistance of aluminum | Body structure, wheels, engine components, exhaust system parts | ||||||||||||

| Painting | Offers colored coatings with corrosion protection and preservation | Body paint, interior parts, exterior trim | ||||||||||||

| Sand blasting | Produces rough surfaces, beneficial for paint adhesion | Body surface treatment, rust surface treatment | ||||||||||||

| Bead Blasting | Removes oxide layers, cleans surfaces, improves surface finish | Engine components, braking system parts, chassis parts | ||||||||||||

| Zinc plating | Enhances corrosion resistance of parts | Screws, nuts, body structure parts | ||||||||||||

| Chrome Plating | Provides good visual effects and corrosion resistance | Door handles, grilles, exhaust pipes | ||||||||||||

Custom Automotive Parts Case Study

Our Partners

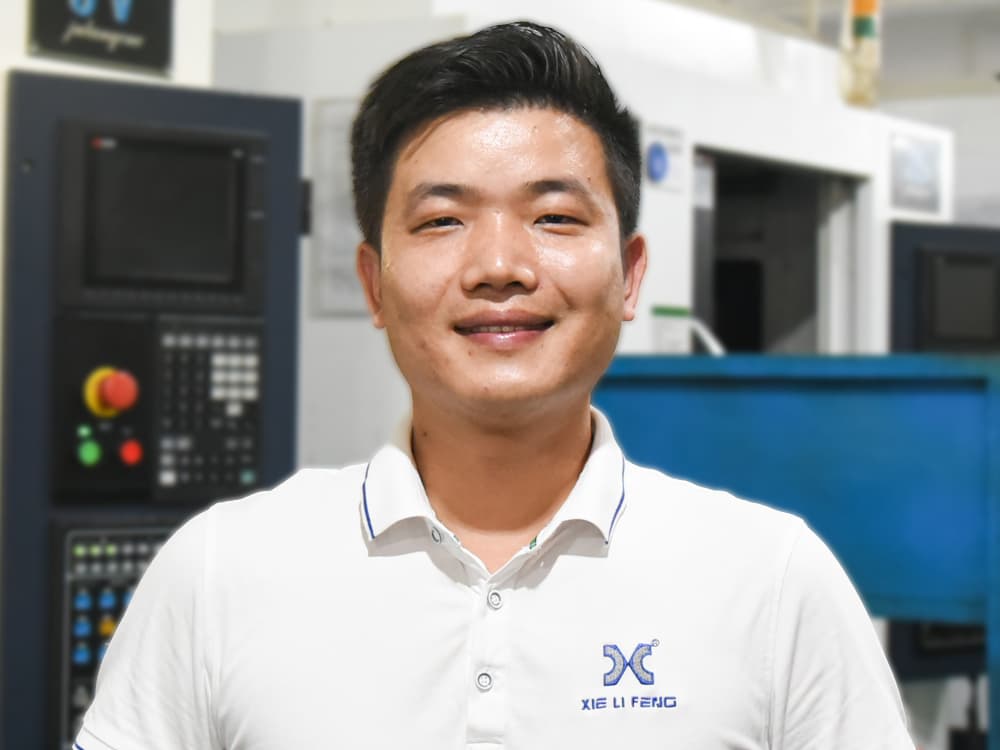

Automotive Parts Engineer Henry from Xielifeng Has Something to Say

Senior Engineer Henry, 15 years of experience in the automotive industry, specializing in precision parts for engines, transmissions, and suspension systems. Familiar with ISO/TS 16949 standards and automotive industry quality requirements, ensuring compliance with strict tolerance and safety standards. Henry sorted out relevant industry knowledge for your reference

How do you ensure compliance with automotive industry standards during machining?

We strictly adhere to ISO/TS 16949 and customer-specific standards throughout the production process. Our quality control team conducts in-line inspections and final inspections to ensure every part meets the required specifications. Additionally, Statistical Process Control (SPC) methods help us monitor and maintain quality throughout production.

What materials do you recommend for automotive components requiring high strength and heat resistance?

For components like engine blocks and brake systems, we recommend aluminum alloys (6061, 7075) or stainless steel for their high strength-to-weight ratios. Titanium alloys are ideal for high-performance applications due to their exceptional heat resistance.

How do you handle the machining of complex geometries in automotive parts?

We use 5-axis CNC machines to accurately machine complex geometries with tight tolerances. Our engineers also develop custom toolpaths and simulate machining processes to ensure efficient material removal while maintaining precision.

What challenges arise when machining engine components, and how do you address them?

Engine components demand high precision and dimensional stability, especially under extreme temperatures and stress. We use high-strength materials like stainless steel and conduct thermal testing to ensure dimensional stability. Furthermore, our real-time monitoring systems detect tool wear early, ensuring consistent quality.

How do you manage large production orders while maintaining quality?

We implement lean manufacturing principles to optimize workflow and reduce waste. Our modular production lines allow us to quickly adjust to different product specifications. Additionally, we conduct random sample testing throughout the process to ensure that quality remains consistent.

How do you ensure proper fit for automotive components during assembly?

We collaborate closely with clients to align with their assembly requirements and CAD models. Our pre-assembly inspections focus on critical dimensions, such as bearing seats and shaft alignments, ensuring a precise fit. We also conduct functional tests to validate performance before final delivery.

How Xielifeng Works

From quotation to delivery, we provide efficient, high-quality services, making manufacturing more convenient.

01

Upload drawing

CAD files: 2D: DXF | DWG | PDF 3D: STP | STEP |IGS | IGES| X_T | SLDPRT

02

DFM Evaluation & Quote

- Drawing review

- Process analysis

- Material inspection

- Feasibility proposal

- Cost estimation

03

Order Confirmtion & Production

- Sample processing

- Sample quality inspection

- Customer confirmation

- Mass production plan

04

Quality Inspection & Delivery

- Raw material inspection

- First piece inspection

- Process inspection

- Final inspection

- Inspection report