IOS 9001

IOS 14001

How Xielifeng Works

The process of ordering custom machined parts at XIELIFENG machining is simple and straightforward, and from initial consultation to final delivery, we ensure professionalism, efficiency and transparency every step of the way.

Purchaser needs to be responsible: Steps 1 and 4

Producers need to take responsibility: Steps 2, 3, 5, 6

Contact Us

DFM Evaluation & Optimization

Get a Quote

Order Confirmation

Production & Quality Inspection

Packing &

Delivery

Step 1: Contact us

Some information to tell us

A.Drawing (Required)

2D: DXF | DWG | PDF 3D: STP | STEP | IGS | IGES | XT | SLDPRT

B. Material (Required)

C.Tolerance (Required)

D.Quantity (Required)

E.Finish (if needed)

F. Provide the address for delivery time (if needed)

Step 2: DFM Evaluation & Optimization

21 professional engineers are at your service online 24/7

Drawing Review

Engineers conduct a detailed review of the drawings provided by the purchaser, checking that all dimensions, tolerances, materials, and surface treatment requirements are clear and reasonable.

Process Analysis

Evaluate the geometry and complexity of the part to determine the appropriate machining processes.

Analyze whether the part requires unique fixtures or tools and identify any machining challenges.

Material Inspection

Please verify the availability and suitability of the required materials for the chosen machining processes.

Consider the machinability, cost, and delivery time of the materials.

Feasibility

Engineers summarize evaluation results and suggestions in a feasibility report.

If issues arise, they propose design modifications or solutions to the purchaser.

Cost Estimation

Estimate costs based on machining processes, material costs, and estimated machining time.

Assess cost optimization opportunities through design changes or process improvements.

Step 3: Get a Quote

You will receive a quote within 24H

Parts Price

Lead Time

Packing Specifications

Shipping Cost

Step 4: Order Confirmation

Confirm Drawings with Xielifeng

Confirm Quantity with Xielifeng

Confirm Delivery Date with Xielifeng

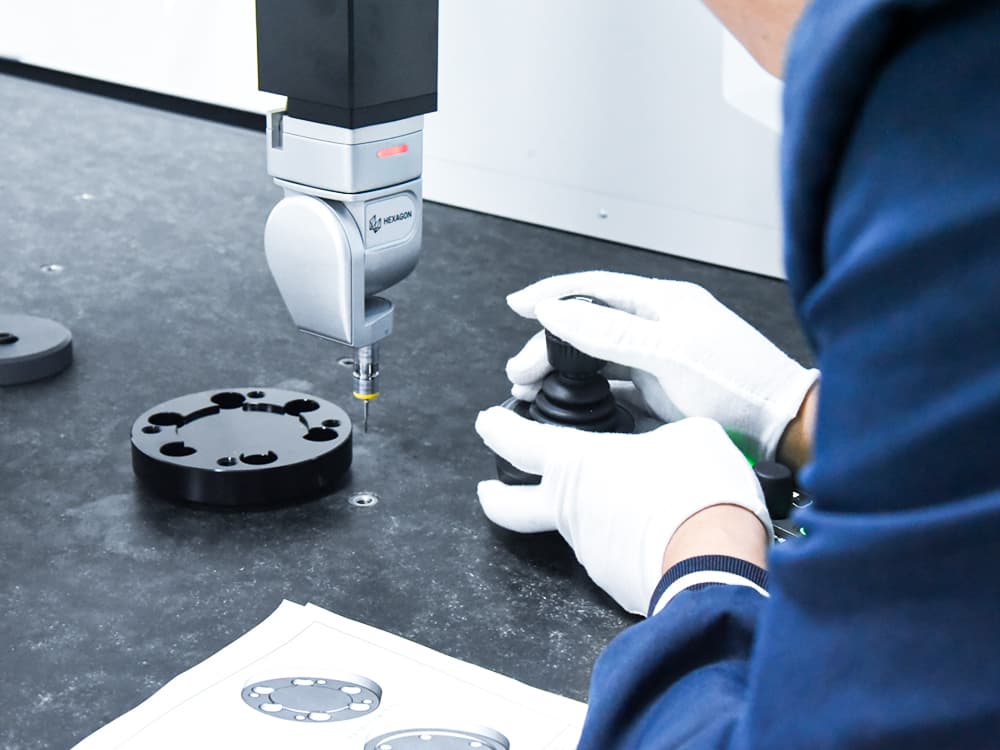

Step 5: Production & Quality Inspection

Sample Production & Mass Production

01 Sample Processing

Process samples according to the process plan.

02 Sample Inspection

Verify the processing results through measurement and testing.

03 Sample Video Confirmation

We send sample photos and videos to the purchaser for initial confirmation, followed by shipping the physical samples for their inspection and final approval.

04 Physical Sample Confirmation

Upon receiving the physical samples, the purchaser can request modifications if needed. Engineers will make adjustments based on the purchaser’s feedback.

05 Mass Production Planning

Once the purchaser approves the samples, we create a mass production plan, covering the timeline, material sourcing, and equipment scheduling.

06 Mass Production Quality Inspection

Monitor tool wear, adjust parameters, and check equipment while Continuously improving the process with real-time data analysis and feedback.

Quality Inspection

01

Raw Material Inspection

All raw materials are strictly inspected for composition, performance, and appearance to meet specifications.

02

First Part Inspection

Before mass production, initial parts are produced to ensure the production process and equipment settings are correct.

03

In-Process Inspection

Random inspections are conducted at regular intervals during production to ensure product quality.

04

Final Inspection

After production, each batch undergoes a comprehensive inspection to ensure all products meet customer requirements.

05

Pre-Packaging Inspection

Before packaging, a final inspection is conducted to ensure the parts will not be damaged during transport.

06

Factory Inspection Report

Before shipment, a detailed factory inspection report is provided for the purchaser’s reference.

Step 6: Packing & Delivery

01-08 Packaging Solutions for Different Types of Parts

01 Small and Durable Parts (Lightweight)

Inner Packaging:

Plastic Bag: Suitable for dust and moisture protection.

Bubble Wrap: Provides essential shock protection.

Outer Packaging:

Cardboard Box: Economic and practical for short-distance transportation and storage.

Foam Peanuts: Add foam peanuts inside the box to prevent movement.

02 Small, Fragile Parts

(Lightweight)

Inner Packaging:

Bubble Wrap: Wraps the entire part, providing good shock protection.

Foam Lining: Custom foam lining shaped to fit the part.

Outer Packaging:

Corrugated Box: Sturdy and durable, it provides extra protection.

Double-Layer Box: Adds layer for extra cushioning.

03 Medium-Sized Parts

(Moderate Weight)

Inner Packaging:

Bubble Wrap or Foam Lining: Provides shock and scratch protection.

Anti-Rust Paper: Wraps metal parts prone to rust.

Outer Packaging:

Corrugated Box: Suitable for most medium-sized parts.

Plastic Box: More durable, ideal for long-distance transport and reuse.

Fillers (e.g., Foam Peanuts or Paper Shreds): Prevents parts from moving inside the box.

04 Large Parts

(Heavier Weight)

Inner Packaging:

Custom Foam Lining: Shaped to fit the part, ensuring it is secure and protected.

Anti-Rust Paper or Bags: Protects metal parts from corrosion.

Outer Packaging:

Wooden Crate: Sturdy and durable, suitable for heavy parts and long-distance transport.

Metal Crate: Provides more robust protection for high-value and high-precision parts.

Stretch Wrap: Secures parts on oversized pallets with stretch wrap.

05 High-Precision and High-Value Parts

Inner Packaging:

Custom Foam Lining: Conforms perfectly to the part’s shape, providing comprehensive protection.

Vacuum Bag: Prevents oxidation and corrosion.

Outer Packaging:

Metal or Flight Case: Provides top protection, ideal for long-distance and international transport.

Multi-Layer Packaging: Inner layer with foam and anti-rust materials; outer layer with a sturdy wooden or metal case.

06 Moisture and Dust Resistant Parts

Inner Packaging:

Plastic or Vacuum Bag: Seals parts to prevent moisture and dust entry.

Desiccant: Adds desiccant packets inside the packaging to absorb residual moisture.

Outer Packaging:

Sealed Plastic Box: Provides better moisture resistance and is suitable for long-term storage.

Double-Layer Cardboard Box: Adds an extra layer to prevent moisture entry further.

07 Corrosion-Prone Metal Parts

Inner Packaging:

Anti-Rust Paper or Bags: Wrap parts to prevent oxidation and corrosion.

Vacuum Packaging: Vacuum seal to reduce air exposure.

Outer Packaging:

Plastic or Metal Box: Provides additional protection and long-term storage capability.

Waterproof Coated Wooden Crate: Use a wooden crate with a waterproof coating for more significant parts.

08 Assembled Parts or Kits

Inner Packaging:

Divided Foam Lining: Custom foam dividers will fit each part separately.

Plastic Dividers: Separate parts to prevent contact.

Outer Packaging:

Corrugated or Plastic Box: Suitable for most assembled parts or kits.

Pallet with Stretch Wrap: Use pallets and stretch wrap for larger quantities.

Shipping Methods: Via Express, Air, or Sea

| Region | Representative Countries | Courier (DHL, FedEx, UPS) | Air Freight | Sea Freight | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| North America | USA, Canada | 3-5 business days | 7-10 business days | 25-35 days | |||||||||

| Europe | Germany, UK, Spain, Sweden | 3-5 business days | 7-10 business days | 30-40 days | |||||||||

| South America | Brazil, Argentina | 5-7 business days | 9-12 business days | 40-50 days | |||||||||

| Middle East | Israel, UAE, Saudi Arabia | 3-5 business days | 7-10 business days | 25-35 days | |||||||||

| Asia | Japan, Korea, India, Thailand, Philippines | 2-4 business days | 5-8 business days | 15-25 days | |||||||||

| Oceania | Australia, New Zealand | 3-5 business days | 7-10 business days | 25-35 days | |||||||||