What is Wire EDM

Wire EDM, or Electric Discharge Machining, is a machining process that uses a thin electrically conductive wire to cut or shape objects. It is commonly used to create complex shapes and features in hard or difficult-to-machine materials such as aerospace alloys, tool steels, and titanium.

The wire EDM process involves submerging the workpiece and the wire electrode in a dielectric fluid, usually deionized water, while applying a voltage between them. As the voltage is applied, electrical sparks or discharges occur between the wire and the workpiece, melting and vaporizing small portions of the material. These discharges create a small crater, known as a spark crater, on the surface of the workpiece. The wire is constantly moved along the desired cutting path, following a pre-programmed computer-aided design (CAD) file or instruction.

Since the wire used in wire EDM is very thin (typically between 0.1 to 0.3 mm in diameter), it allows for very precise and intricate cuts with tolerances as small as a few micrometers. It can also cut through materials with a hardness of up to 65 HRC (Rockwell hardness scale), making it ideal for cutting hardened tool steels and other exotic materials.

The advantages of wire EDM include high precision, excellent surface finish, and the ability to cut complex shapes and intricate details. It can also be used to create very small features and narrow slots that may be impractical or impossible to achieve using other machining methods.

However, wire EDM is relatively slow compared to other machining processes, and it may not be suitable for large-scale production due to its slow cutting speed. It also requires careful setup and programming, as well as skilled operators to ensure optimal results.

Overall, wire EDM is a specialized machining process that is widely used in industries such as aerospace, automotive, mold and die making, and electronics for its ability to cut hard and difficult-to-machine materials with high precision and intricate detail.

How is Wire EDM Working

Wire EDM (Electrical Discharge Machining) is a non-traditional machining process used to cut intricate shapes in electrically conductive materials. Here is a simplified explanation of how it works:

- Setup: The material to be machined is mounted on a worktable, and a thin, electrically conductive wire electrode is also attached to the worktable. The wire and the workpiece are submerged in a dielectric fluid (such as deionized water) to promote efficient electrical discharge and cooling.

- Generators: The Wire EDM machine has two generators: power and control generator. The power generator provides a high voltage, high-frequency electrical current to the wire electrode, creating an electrical potential difference between the wire and the workpiece. The control generator controls the power and timing of electrical discharges.

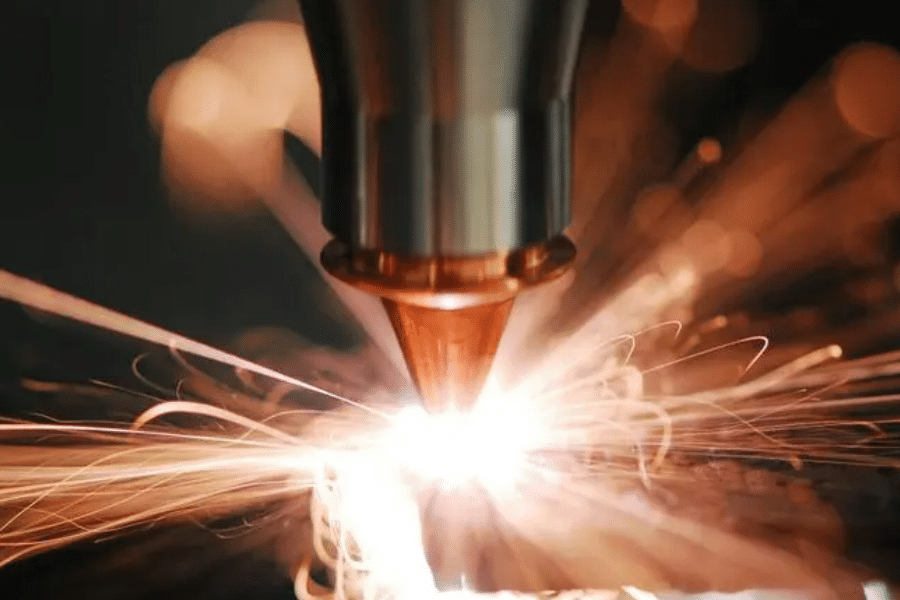

- Electrical Discharge: When the wire electrode approaches the workpiece, a small gap (spark gap) is maintained between them in the dielectic fluid. The control generator then sends short bursts of electrical pulses (known as sparks) to jump the gap.

- Spark Erosion: The sparks, or electrical discharges, cause controlled micro-explosions at the gap, vaporizing and melting a small portion of the workpiece. This process is called spark erosion. The dielectric fluid cools the electrode, workpiece, and removes the debris created during spark erosion.

- Wire Feed and Motion: As the wire electrode continuously moves along the desired cutting path, the wire feed mechanism feeds fresh wire from a spool to maintain a consistent wire diameter. The worktable can also move in multiple axes to achieve complex shapes.

- Kerf: The spark erosion continues as the wire electrode cuts through the material, creating a narrow slot known as the kerf. The wire electrode does not physically touch the workpiece, and erosion occurs solely through the electrical discharges.

- Finishing: Once the desired shape is cut, the Wire EDM process can provide smooth surface finishes. This is achieved by using fine wire diameters, precise control of electrical discharges, and appropriate dielectric fluid with additives.

Wire EDM offers several advantages, such as high precision, no mechanical forces applied to the material, and the ability to cut intricate shapes and hard materials. However, it is a relatively slower process compared to traditional machining methods.