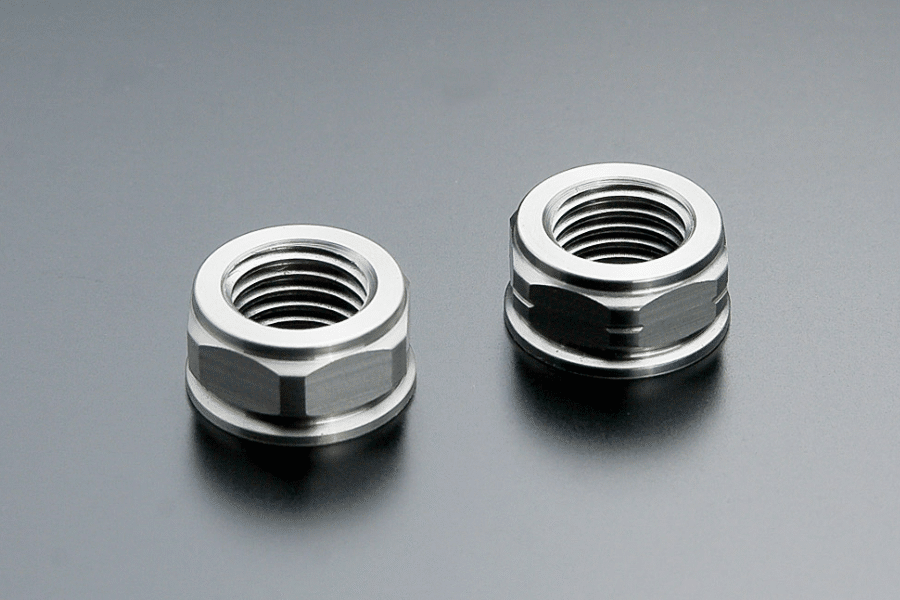

CNC machining titanium can be a challenging process due to the properties of the material. Titanium is a strong and lightweight metal that is highly resistant to corrosion, but it is also notoriously difficult to machine due to its low thermal conductivity and high chemical reactivity. However, with the right tools, techniques, and expertise, it is possible to achieve high-quality results when machining titanium using CNC technology.

Here are some tips for CNC machining titanium:

Use the right cutting tools: Carbide or diamond-coated cutting tools are typically used for machining titanium because they can withstand the high temperatures and pressures generated during the cutting process. It is important to choose the right type of cutting tool based on the specific application.

Use proper tool geometry: The geometry of the cutting tool is also critical for achieving high-quality results when machining titanium. A positive rake angle, large relief angle, and sharp cutting edge are typically recommended for machining titanium.

Use the right coolant: Using the right type of coolant is critical for controlling the heat generated during the cutting process. Water-based coolants are typically used for machining titanium because they provide good cooling and lubrication.

Optimize cutting parameters: Cutting speed, feed rate, and depth of cut are all important parameters that should be optimized for each specific application. High cutting speeds and low feed rates are typically recommended for machining titanium.

Minimize vibration: Vibration can cause poor surface finish and tool wear, so it is important to minimize vibration by using the right cutting parameters, rigidity of the machine, and tooling setup.

Use a rigid setup: A rigid setup is critical for achieving high-quality results when machining titanium. This includes using a rigid machine, tool holder, and workholding system.

By following these tips, you can achieve high-quality results when CNC machining titanium. However, it is important to note that machining titanium is a complex process that requires expertise and experience. If you are not familiar with the process, it is recommended to consult with a professional machinist who has experience in machining titanium.

Titanium vs. Aluminum

Titantium and aluminum are both widely used materials in various industries. Here are some differences between the two:

Strength: Titanium is much stronger than aluminum, which makes it an ideal material for aerospace and military applications where strength and durability are critical.

Weight: Aluminum is much lighter than titanium, which makes it an ideal material for applications where weight is a primary consideration, such as transportation and consumer electronics.

Corrosion resistance: Titanium is highly resistant to corrosion, making it an ideal material for marine and chemical applications. Aluminum, on the other hand, is susceptible to corrosion unless it is coated with a protective layer.

Cost: Titanium is much more expensive than aluminum, mainly because of its rarity and difficulty in processing.

Machinability: Aluminum is much easier to machine than titanium, which makes it an ideal material for high-volume production applications.

Ultimately, the choice between titanium and aluminum depends on the specific application, the required properties, and the budget.

Search terms of this article:

cnc machining titanium