Aluminum alloy laser welding used in die casting parts

Lightweight increases the amount of aluminum alloy, following the trend, the size of aluminum alloy die castings is getting bigger and bigger. However, due to the characteristics of high thermal expansion coefficient, low melting point, and easy oxidation of aluminum alloys, problems such as deformation, pores, and low welded joint coefficients caused by excessive heat input in the traditional stamping and welding process are magnified, and the cost of aluminum alloys under the old process High efficiency is low, and integrated die-casting comes into being. Aluminum alloy integrated die-casting redesigns multiple independent parts that originally needed to be assembled in large-scale structural parts, and uses a super-large die-casting machine to form one-time die-casting to directly obtain complete parts, greatly reducing stamping and welding processes, and optimizing structural parts performance, is expected to accelerate the penetration of aluminum alloys.

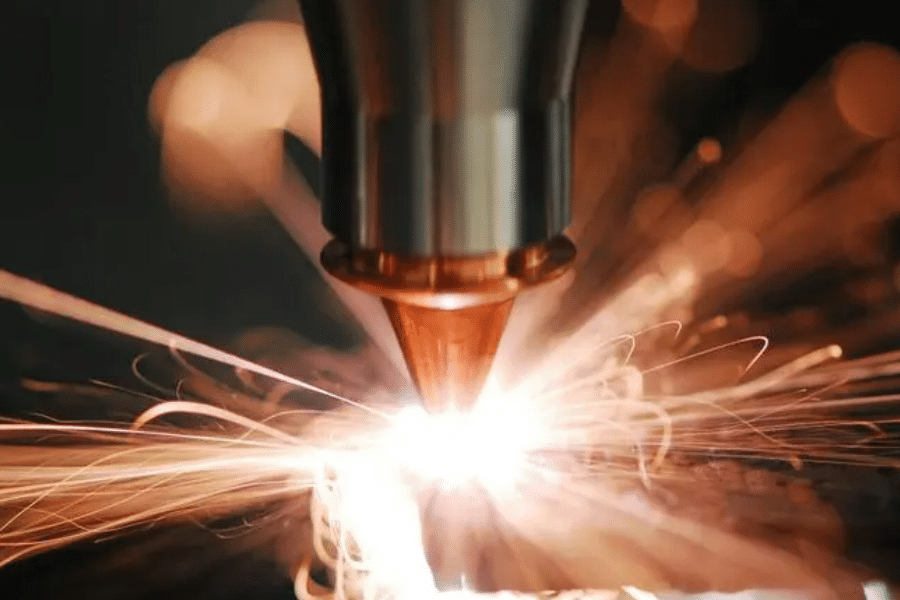

In the subsequent production process, laser welding is often used, and its aluminum die castings will encounter various problems during laser welding, mainly because its aluminum alloy is a non-ferrous metal, which will All kinds of light have strong reflectivity. As a more intense beam, laser light is more likely to cause reflection on the surface of aluminum alloy.

When laser welding aluminum alloy, you must strictly pay attention to the operation and increase the power density of the laser to prevent it from being reflected or transmitted, and try to weld the aluminum alloy with a high density in a short time, so that you can Avoid problems such as reflexivity.

Advantages of laser welding machine

Aluminum alloy laser welding lasers are divided into two types: pulsed lasers and continuous lasers. The pulsed laser beam is very concentrated and focused when the wavelength of the pulsed laser is 1064nm, and the pulse single-point energy is larger than that of the continuous laser. The advantage of the laser welding machine is that it has very concentrated energy, fast welding speed, small weld width, small heat-affected zone and deformation, no air holes, less pollution, flat and beautiful welding area, after welding Just simple processing. It is especially suitable for products with high requirements on welding seam, and does not require solder, accurate positioning, high degree of automation, and mass production can be realized.

How to use aluminum alloy laser welding machine?

The use method of aluminum alloy laser welding machine is relatively simple, but it is also necessary to master the basic operation method. First of all, for novices, it is best to familiarize yourself with the operation video or the operation manual in order to better grasp the operation method. Secondly, in the actual operation process, pay attention to observe the working status of the aluminum alloy laser welding machine, and deal with it in time if any abnormal situation is found. Proper use of aluminum alloy laser welding machine can not only improve work efficiency, but also prolong the service life of the equipment.